A kind of spider silk-like polymer fiber based on polystyrene porous microspheres and preparation method thereof

A technology of porous microspheres and polystyrene, applied in the field of chemical bionics, can solve the problems of weak interaction between additives and fiber matrix and low cost, and achieve the effects of low cost, weakened influence, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

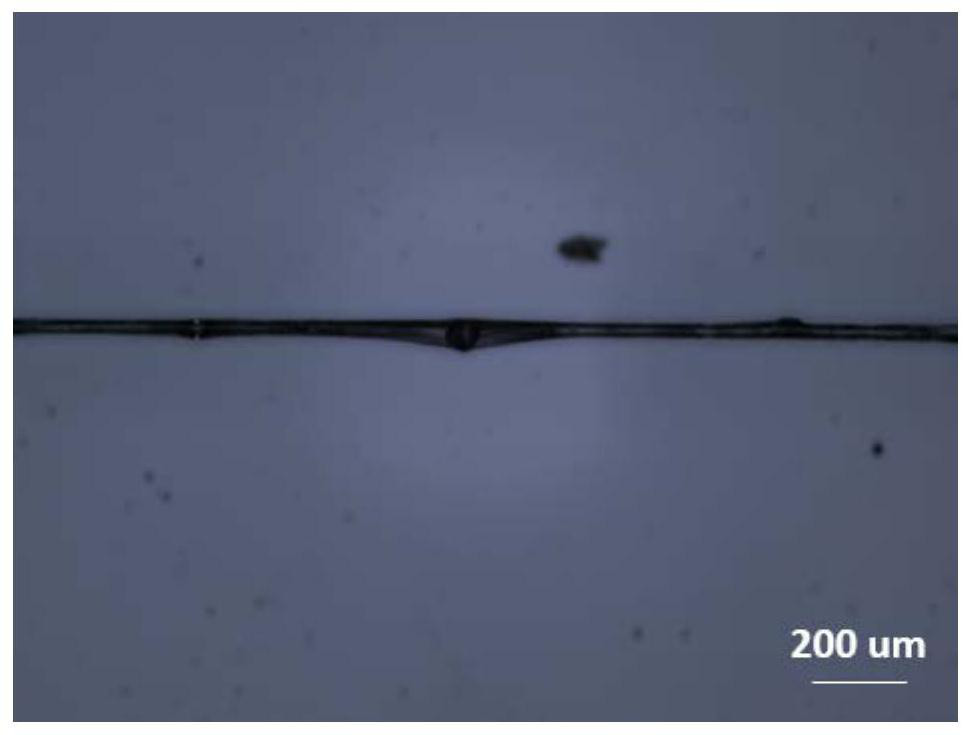

Embodiment 1

[0051] 7 grams of polyvinyl alcohol (PVA 1799, Aladdin, degree of polymerization 1700, degree of alcoholysis 99%), 1.05 grams of polystyrene porous microspheres (IPE-PST30, purchased from the National Biochemical Engineering Technology Research Center, average particle size) diameter of 30 microns, pore diameter of 20 to 120 nanometers, porosity of 20 to 50%), dispersed in 43 grams of 1,4-dioxane (DMSO), heated and stirred at 80 degrees Celsius for 2 hours to obtain a uniform spinning dope. At room temperature, the above spinning dope was extruded into methanol through a peristaltic pump for spinning: the actual extrusion rate was 0.02 ml per minute, the spinneret model was 25G (260 microns in diameter), and the take-up rate was 0.1 m per minute The fibers were kept in the coagulation bath for at least 5 minutes; after being fully dried and collected, the primary fibers were obtained; and the spider silk-like fibers were obtained by thermal drawing at 180 degrees Celsius to 10...

Embodiment 2

[0060] 7 grams of polyvinyl alcohol (PVA 1799, Aladdin, degree of polymerization 1700, degree of alcoholysis 99%), 2.1 grams of polystyrene porous microspheres (IPE-PST30, purchased from the National Biochemical Engineering Technology Research Center, average particle size) diameter of 30 microns, pore diameter of 20 to 120 nanometers, porosity of 20 to 50%), dispersed in 43 grams of 1,4-dioxane (DMSO), heated and stirred at 80 degrees Celsius for 2 hours to obtain a uniform spinning dope. At room temperature, the above spinning dope was extruded into methanol through a peristaltic pump for spinning: the actual extrusion rate was 0.02 ml per minute, the spinneret model was 25G (260 microns in diameter), and the take-up rate was 0.1 m per minute The fibers were kept in the coagulation bath for at least 5 minutes; after being fully dried and collected, the primary fibers were obtained; and the spider silk-like fibers were obtained by hot drawing at 180 degrees Celsius to 8 times...

Embodiment 3

[0062]6 grams of polyvinyl alcohol (PVA 2499, Aladdin, degree of polymerization 2400, degree of alcoholysis 99%), 0.9 grams of polystyrene porous microspheres (IPE-PST30, purchased from the National Biochemical Engineering Technology Research Center, average particle size) diameter of 30 microns, pore diameter of 20 to 120 nanometers, porosity of 20 to 50%) was dispersed in 44 grams of 1,4-dioxane (DMSO), heated and stirred at 80 degrees Celsius for 3 hours to obtain a uniform spinning dope. At room temperature, the spinning dope was extruded into methanol through a peristaltic pump for spinning: the actual extrusion rate was 0.02 ml per minute, the size of the spinneret was 25G (260 microns in diameter), and the take-up rate was 0.1 m per minute. The fibers were kept in the coagulation bath for at least 5 minutes; after being fully dried and collected, the primary fibers were obtained; and the spider silk-like fibers were obtained by hot drawing at 180 degrees Celsius to 8 ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com