Hanging bracket of shot blasting machine

The technology of shot blasting machine and hanger is applied in the field of hanger of shot blasting machine to achieve the effect of improving utilization rate, improving operation efficiency and reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

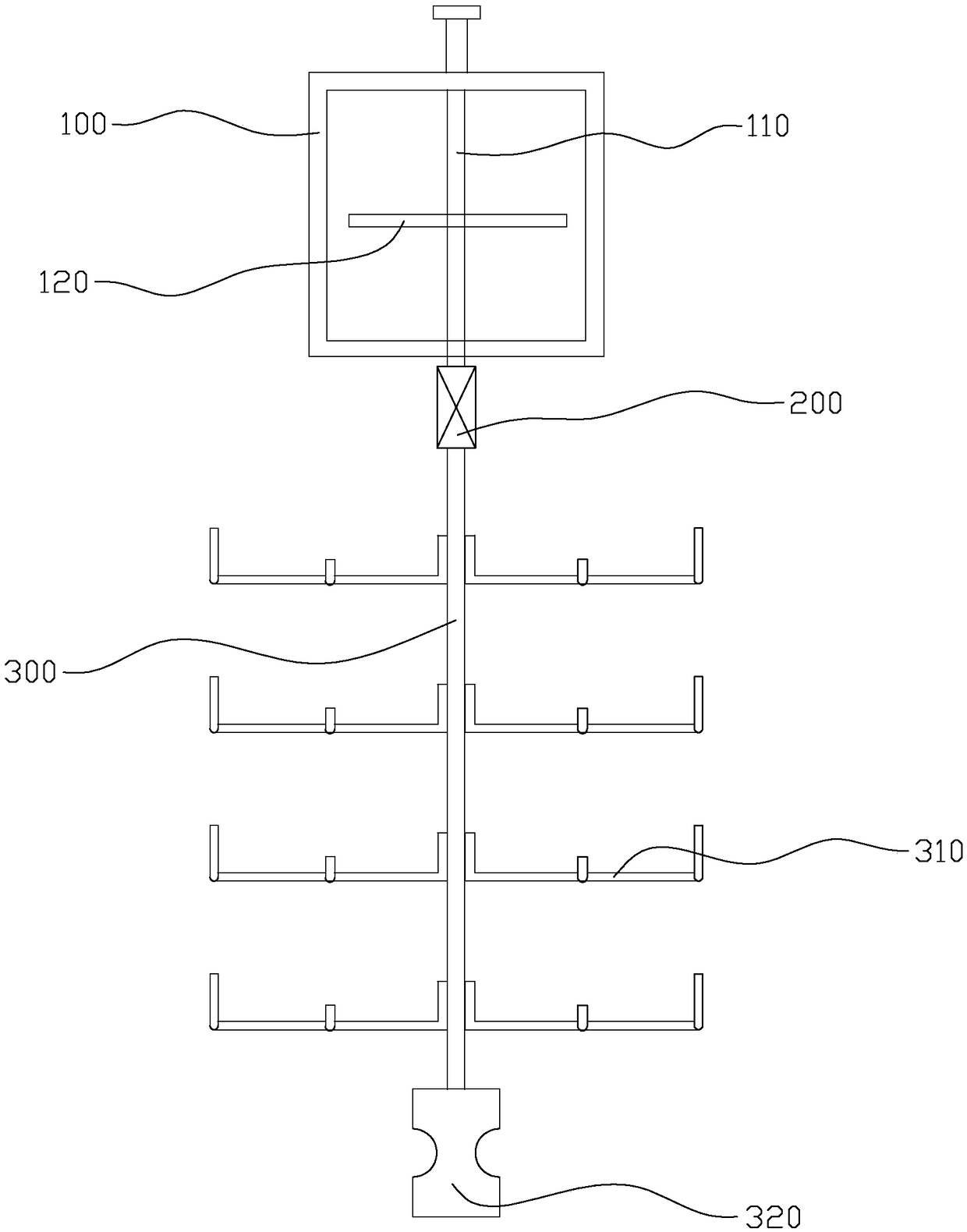

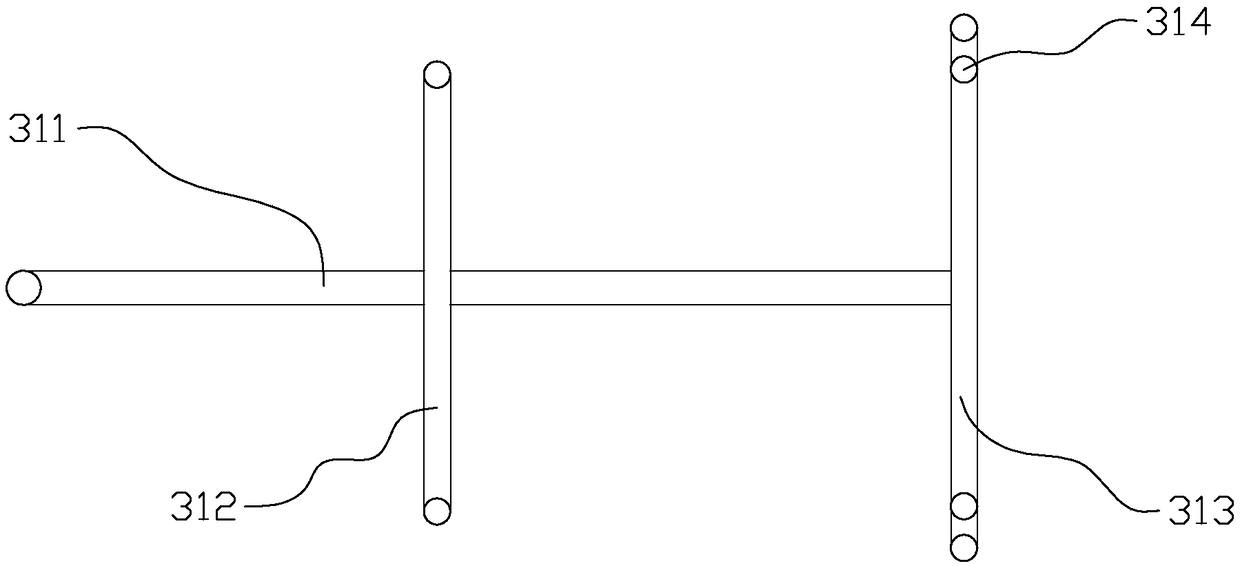

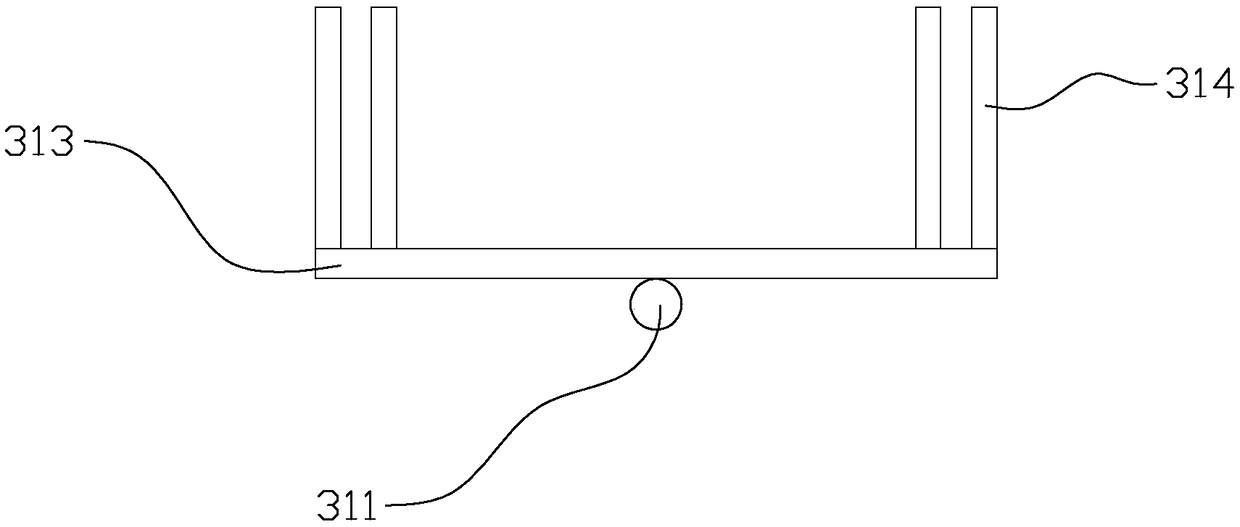

[0017] refer to Figure 1 ~ Figure 4 One embodiment of the present invention provides a hanger for a shot blasting machine, including an upper rotating frame 100, a shock-absorbing connection seat 200, and a main rod 300. A rotating rod 110 is arranged inside the upper rotating frame 100, and the The lower end of the rotating rod 110 is connected to the shock-absorbing connection seat 200, and the main rod 300 is connected to the lower end of the shock-absorbing connection seat 200, and the shaking is reduced through the shock-absorbing connection seat 200 to prevent the cylinder head workpieces from colliding with each other; Four layers of sub-supports 310 are connected to the main pole 300, and each layer of sub-supports 310 is provided with four, and adjacent two-layer sub-supports 310 are staggered from each other; The first longitudinal bar 312 and the second longitudinal bar 313 on the top, the first longitudinal bar 312 is fixed in the middle of the horizontal bar 311,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com