An openable and tightened back door lock capable of ensuring meshing performance and an assembly method

A back door and meshing technology, applied in the field of openable and tight back door locks and assembly, can solve the problems of increasing working hours, wasting manpower, and risking quality assurance, and achieving the effects of reducing difficulty, improving efficiency, and reducing man-hours for adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

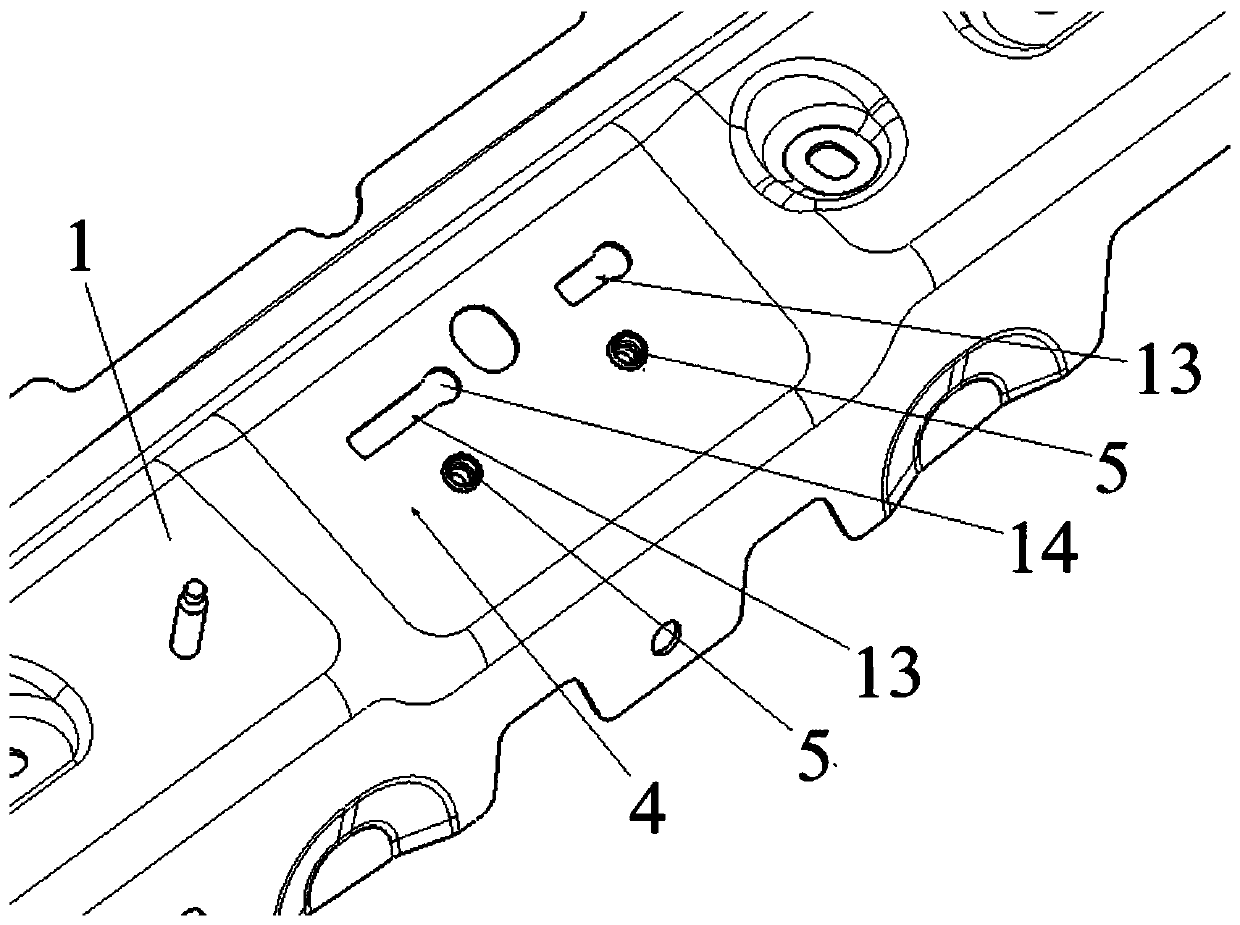

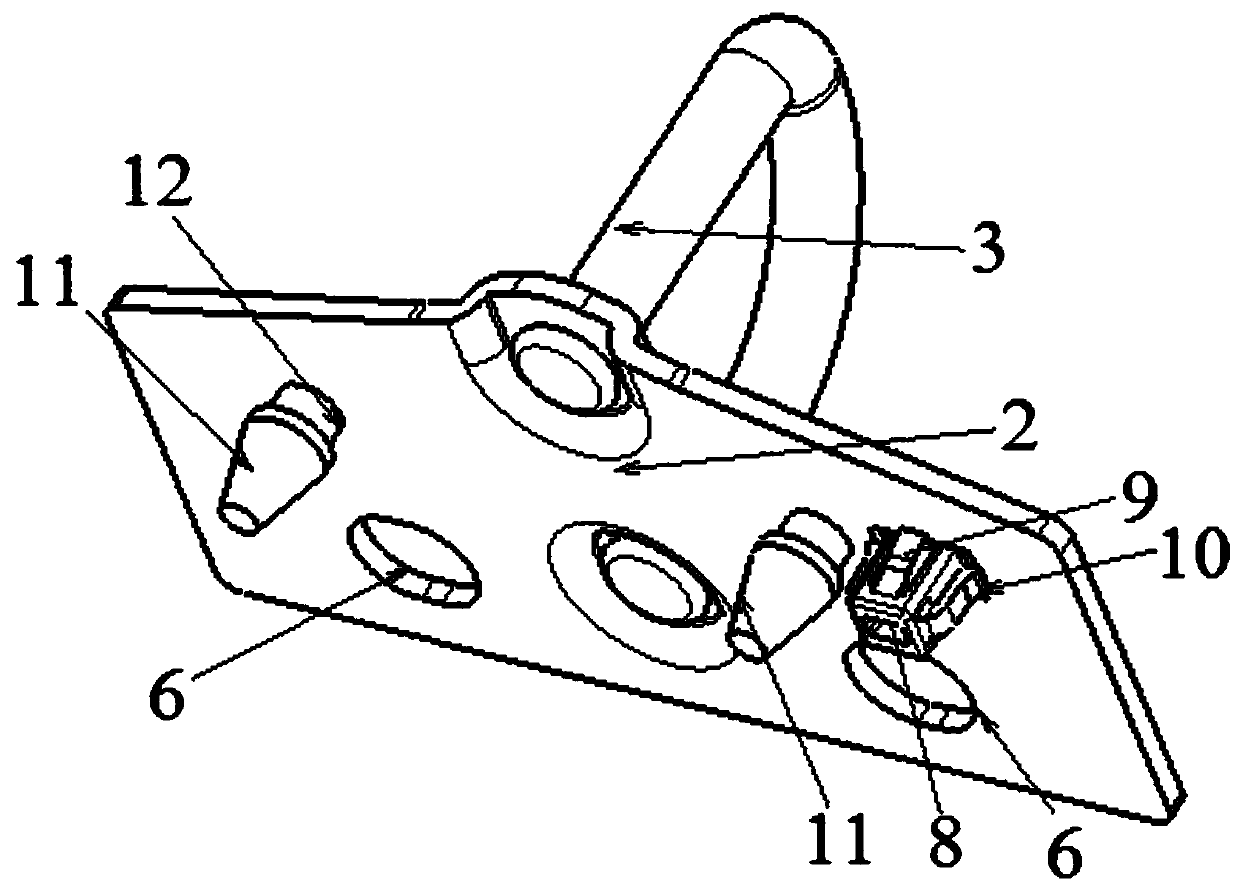

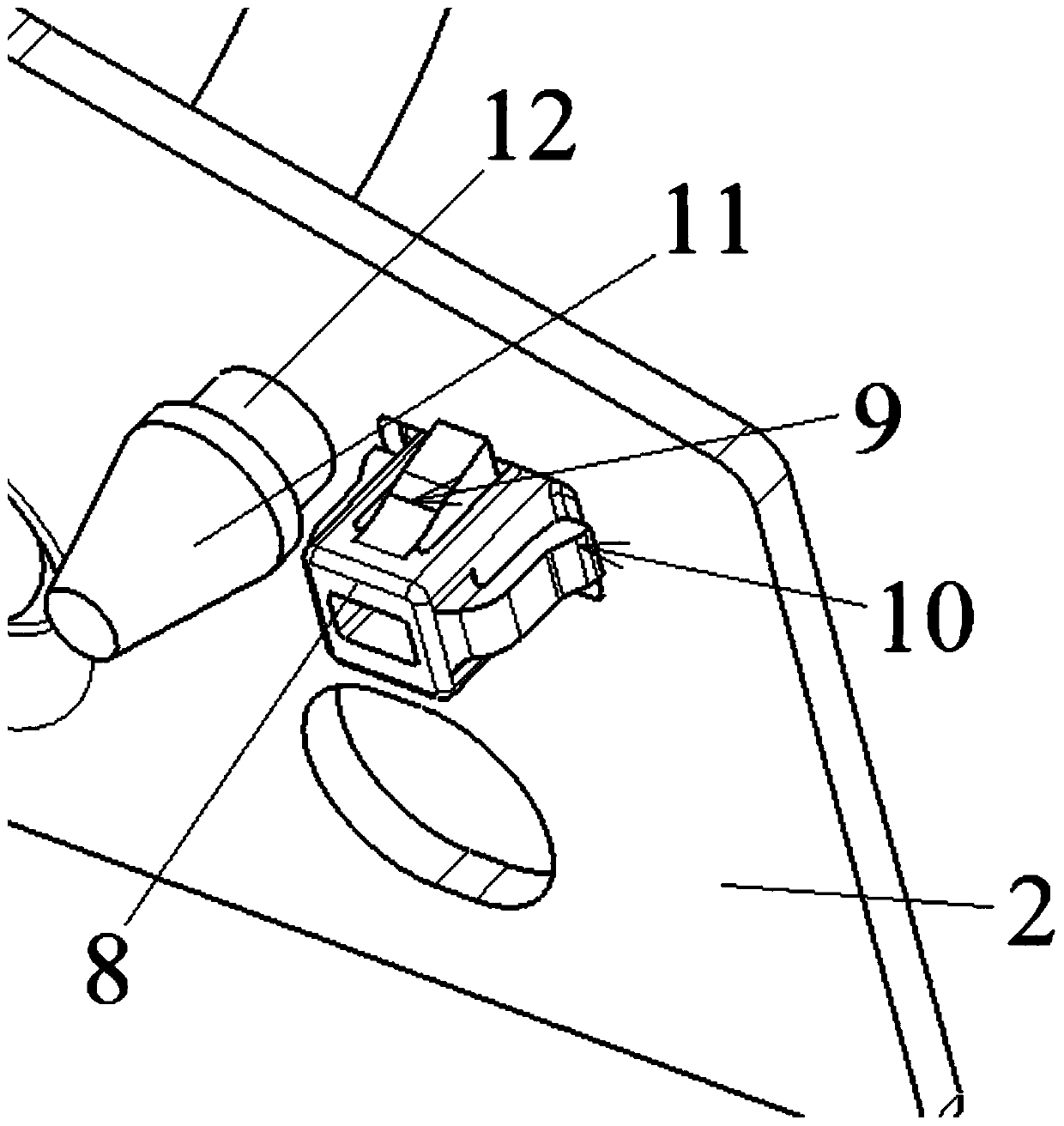

[0026] Such as Figure 1~5 , an openable and tightening back door lock that guarantees meshing performance, including a rear panel 1 and a lock, the lock of this embodiment forms a locking structure of the back door with the lock of the back door after assembly is completed, the lock Including the bottom plate 2 and the lock pin 3, after the lock catch is assembled, the lock on the back door is engaged with the lock pin 3. The base plate 2 of this embodiment is fixed on the rear panel 1 by locking bolts after the lock buckle assembly is completed.

[0027] A tightening surface 4 corresponding to the base plate 2 is provided in the middle of the back panel 1, and a first through hole 5 for fastening the base plate 2 is provided on the tightening surface 4, such as Figure 2~3 As shown, the base plate 2 is provided with a second throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com