Wood-plastic composite material added with Chinese fan palm leaf fiber and application thereof

A technology of wood-plastic composite materials and palm leaves, which is applied in the field of wood-plastic profiles, can solve problems such as limitations in applicability, and achieve the effects of wide source of raw materials, low cost, and simple and convenient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment relates to a wood-plastic composite material added with palmetto leaf fibers and a preparation method thereof. The wood-plastic composite material is composed of the following raw materials in parts by weight:

[0046] Polyvinyl chloride resin powder SG-472 parts;

[0047] 12 parts of hydroxypropyl methacrylate;

[0048] 34 parts palm leaf fiber;

[0049] 10 parts of niobium yttrium tailings powder;

[0050] 3 parts of nanometer bismuth vanate powders;

[0051] 2 parts of JYM-087B rubber powder;

[0052] 1.5 parts of tributoxyethyl phosphate;

[0053] 1 part of compound dispersant:

[0054] 1 part of compound coupling agent;

[0055] 2 parts of compound foaming agent;

[0056] 1.5 parts of antioxidant antioxidant.

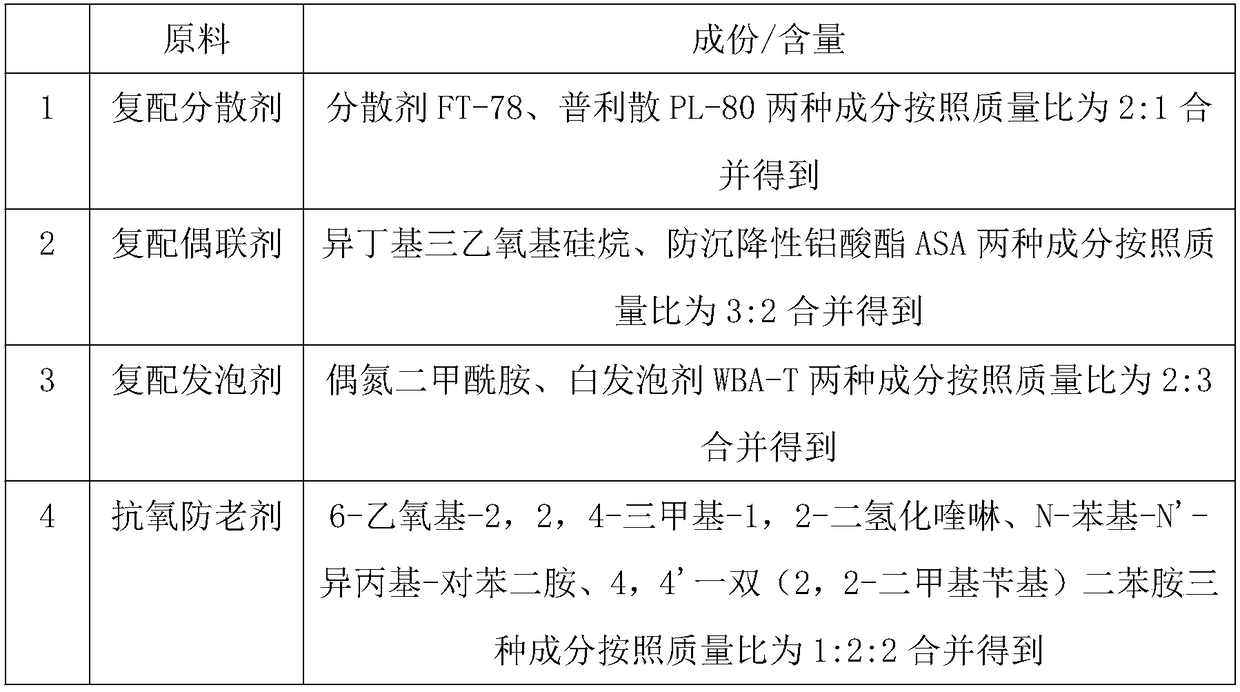

[0057] The selection and preparation of the compound dispersant, compound coupling agent, compound foaming agent and antioxidant anti-aging agent in this embodiment are shown in Table 1 below:

[0058] Table 1

[0059]

[0060] The...

Embodiment 2

[0065] This embodiment relates to a wood-plastic composite material added with palmetto leaf fibers and a preparation method thereof. The wood-plastic composite material is composed of the following raw materials in parts by weight:

[0066] Polyvinyl chloride resin powder SG-476 parts;

[0067] 13 parts of hydroxypropyl methacrylate;

[0068] 36 parts palm leaf fiber;

[0069] 12 parts of niobium yttrium tailings powder;

[0070] 3.5 parts of nanometer bismuth vanate powder;

[0071] JYM-087B rubber powder 2.3 parts;

[0072] 1.7 parts of tributoxyethyl phosphate;

[0073] 1.2 parts of compound dispersant:

[0074] 1.4 parts of compound coupling agent;

[0075] 2.5 parts of compound blowing agent;

[0076] Antioxidant antiaging agent 2 parts.

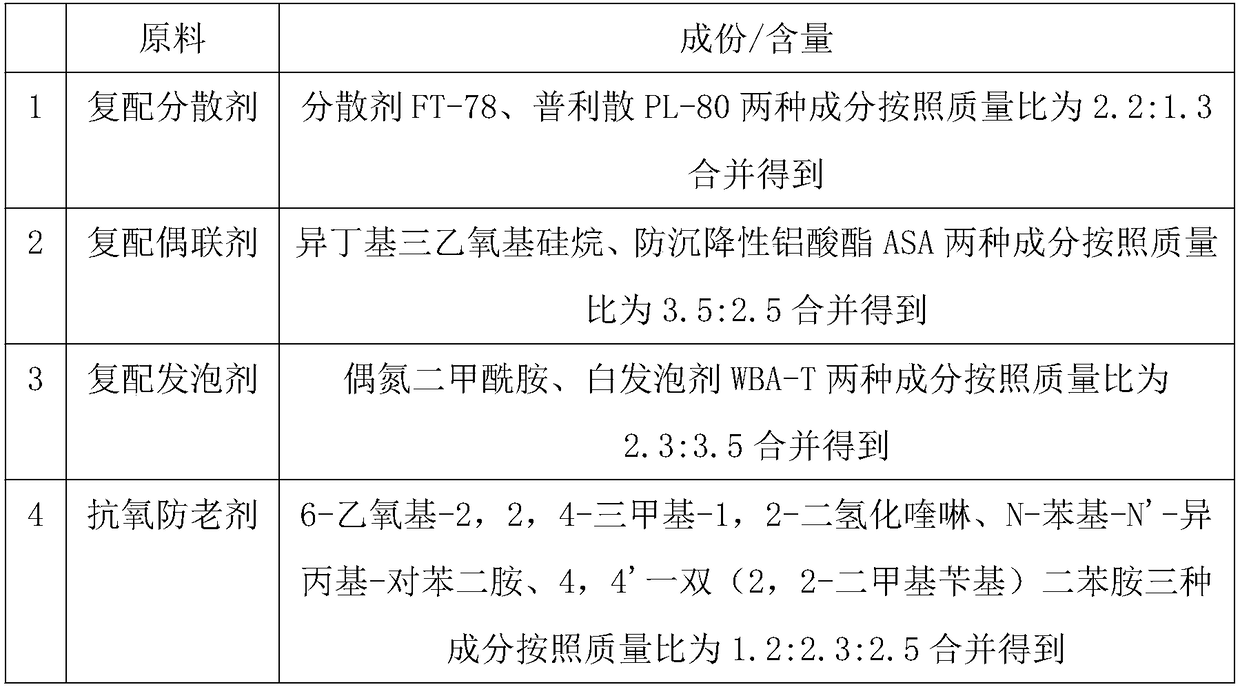

[0077] The selection and preparation of compound dispersant, compound coupling agent, compound foaming agent and anti-oxidant anti-aging agent in this embodiment are shown in Table 2 below:

[0078] Table 2

[0079]

[008...

Embodiment 3

[0085] This embodiment relates to a wood-plastic composite material added with palmetto leaf fibers and a preparation method thereof. The wood-plastic composite material is composed of the following raw materials in parts by weight:

[0086] Polyvinyl chloride resin powder SG-479 parts;

[0087] 14 parts of hydroxypropyl methacrylate;

[0088] 38 parts palm leaf fiber;

[0089] 13 parts of niobium yttrium tailings powder;

[0090] 4 parts of nanometer bismuth vanate powders;

[0091] JYM-087B rubber powder 2.5 parts;

[0092] 2 parts of tributoxyethyl phosphate;

[0093] 1.6 parts of compound dispersant:

[0094] 1.5 parts of compound coupling agent;

[0095] 2.8 parts of compound blowing agent;

[0096] 2.3 parts of antioxidant antioxidant.

[0097] The selection and preparation of compound dispersant, compound coupling agent, compound foaming agent and anti-oxidant anti-aging agent in this embodiment are shown in Table 3 below:

[0098] table 3

[0099]

[0100]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com