Inner rail bender under vertical shaft of logistics track

A technology of shafts and rails, which is applied to the hydraulic equipment used to operate the switch or the circuit breaker, the electrical equipment used to operate the switch or the circuit breaker, and the parts of the railway car body, etc. cost, increase the construction space of the shaft, and occupy the unsightly space, etc., to achieve the effect of beautiful indoor environment, reducing engineering expenses, and simplifying the indoor environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

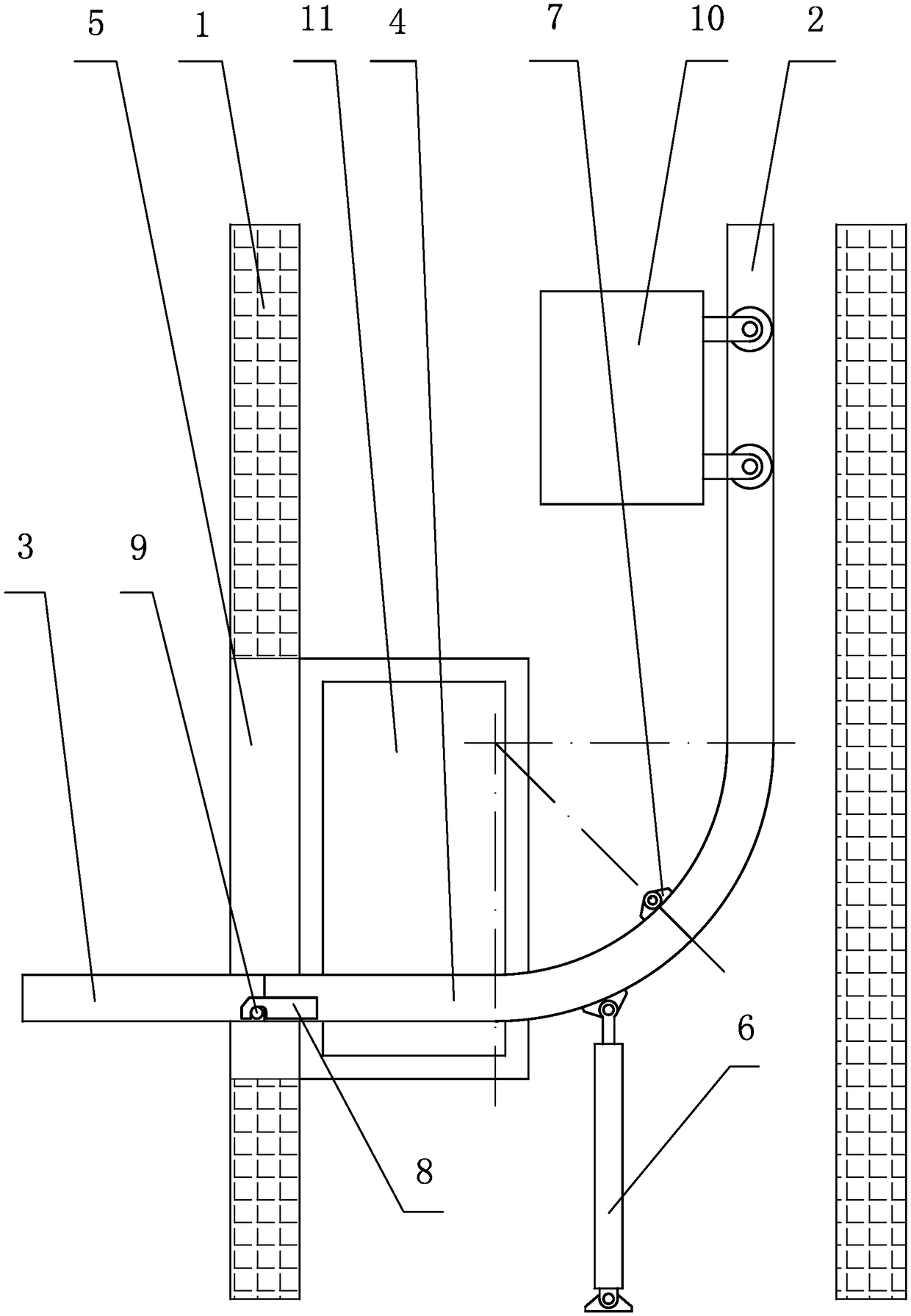

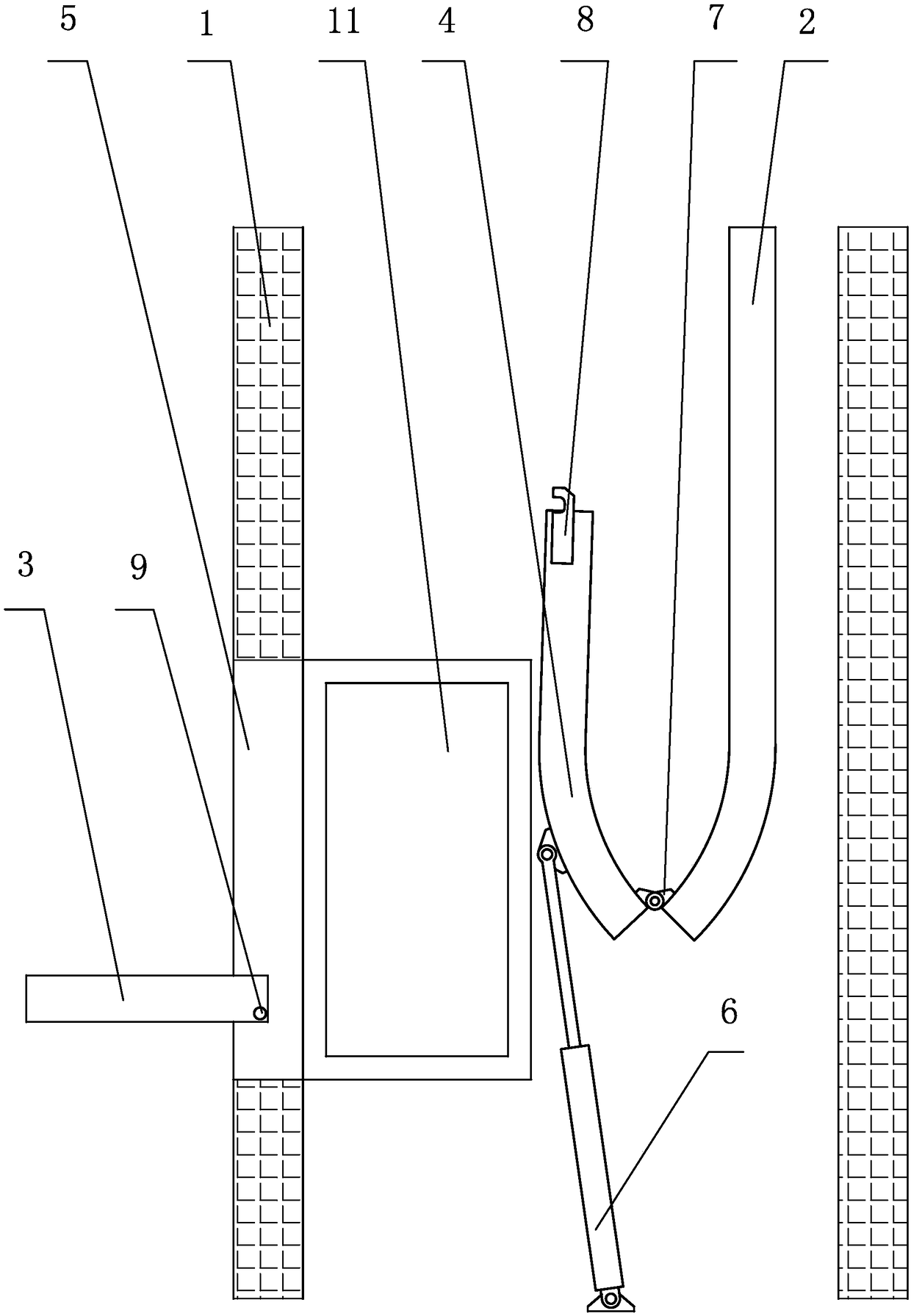

[0020] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0021] The technical scheme of the present invention includes a vertical fixed rail 2 arranged in the shaft 1 corresponding to a certain floor and a horizontal fixed rail 3 arranged on the floor, the horizontal fixed rail 3 (rail back down) fixed on the floor of the floor through the horizontal rail frame, the logistics trolley 10 runs on the horizontal fixed rail 3, and the rear end (flat end) of the horizontal fixed rail 3 facing the shaft 1 is on the front wall of the shaft 1 In the window hole 5 provided above, corresponding to the window hole 5, there is a smoke-proof and fireproof casement window 11 (a rotating window sash) that closes the window hole 5 in the shaft 1; wall) is installed on the vertical track frame, the bottom of the vertical fixed track 2 is a 45 ° curved rail section that is bent inwardly down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com