Novel gear safety perforating device

A punching device, gear technology, applied in the direction of feeding device, boring/drilling, large fixed members, etc., can solve the problems of inconvenient precision, danger, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

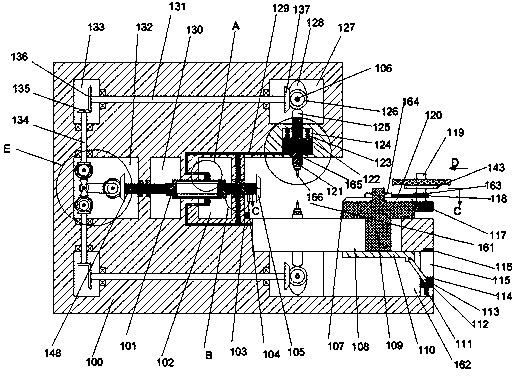

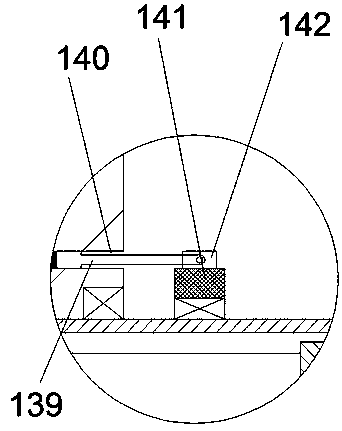

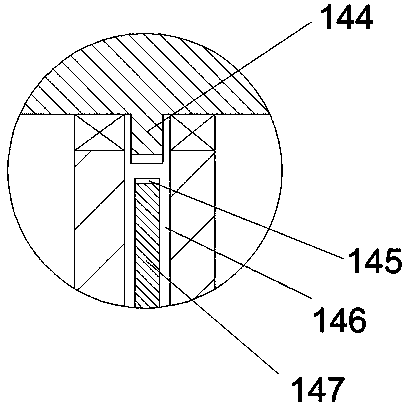

[0011] like Figure 1-Figure 6 As shown, a novel gear safety punching device of the present invention includes a fuselage 100 and a first cavity 132 arranged in the left end wall of the fuselage 100, and the first cavity 132 is rotatably provided with The first rotating shaft 155 extending forward and backward, the rear end of the first rotating shaft 155 is fixedly connected to the first motor 167 in the rear end wall of the first cavity 132, and the outer surface of the first rotating shaft 155 is fixedly arranged There is a sector gear 153 and a first pulley 154 arranged on the rear side of the sector gear 153. The first rotating shaft 155 is symmetrically provided with a rotatable second rotating shaft 151. The outer surface of the second rotating shaft 151 is fixedly arranged with The firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com