High-efficiency crushing device for leather

A crushing device and high-efficiency technology, which is applied in the field of high-efficiency crushing devices for leather, can solve the problem that leather is easy to stick to the side wall or bottom of the crushing frame, and achieve the effect of speeding up the crushing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

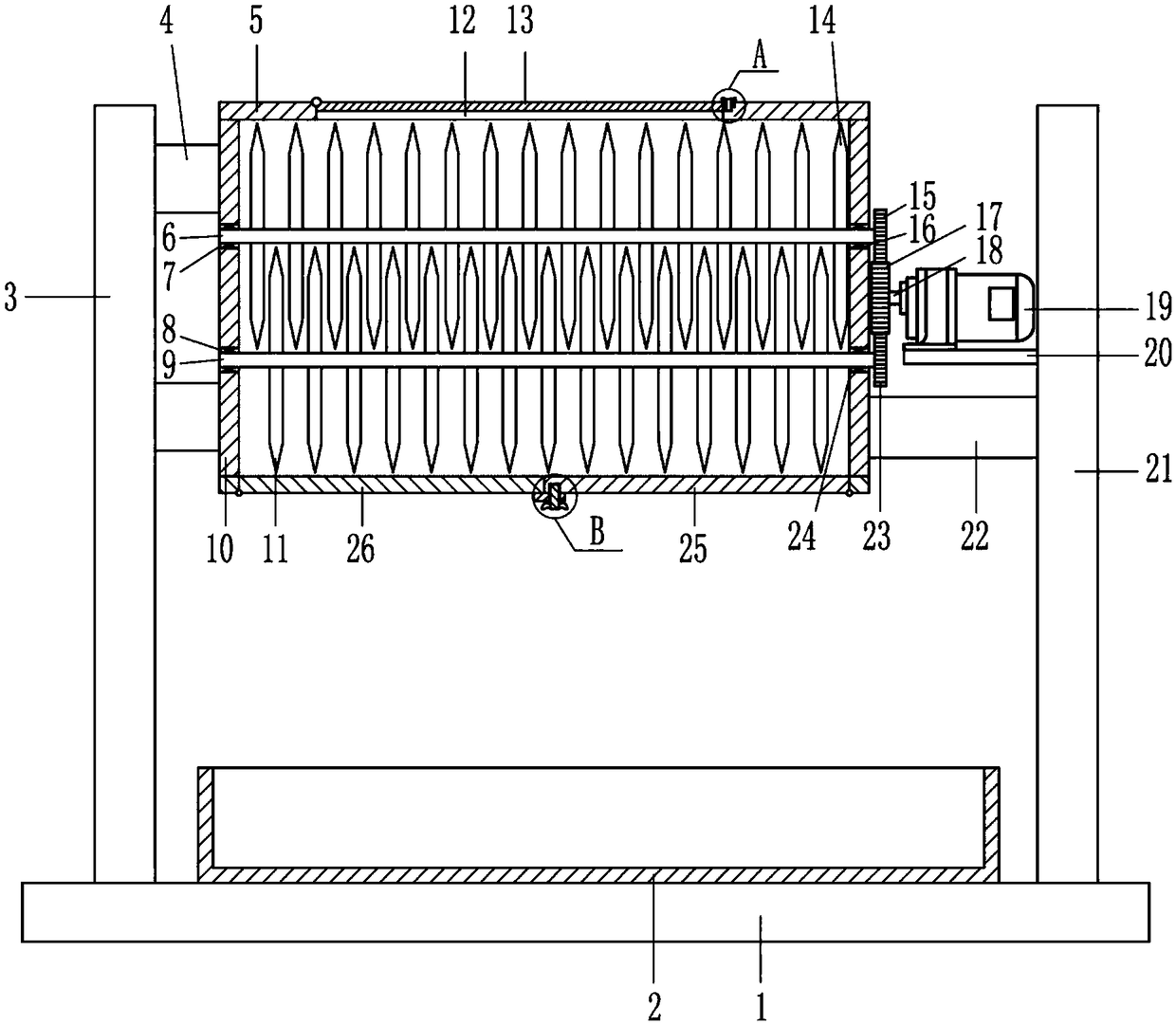

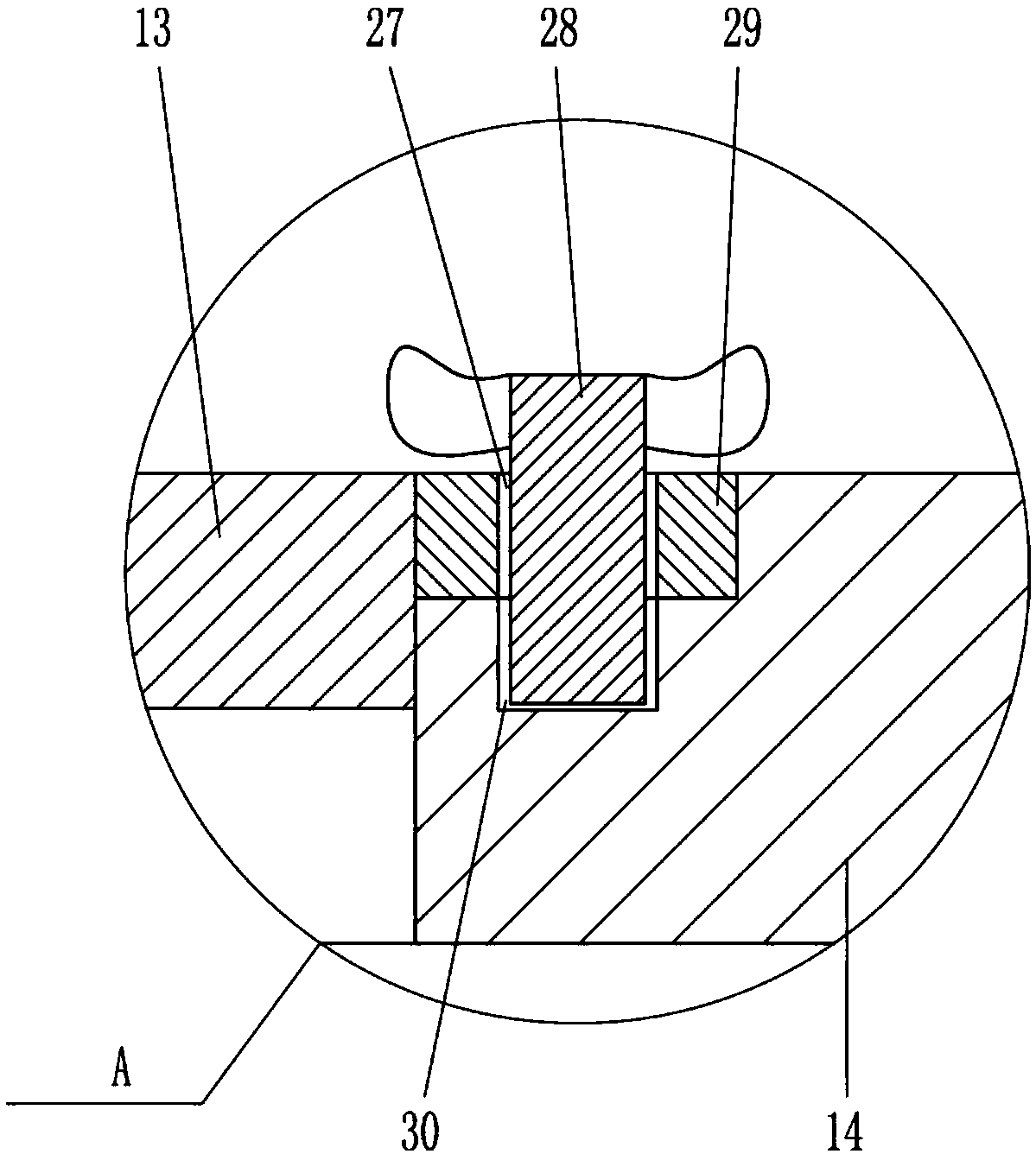

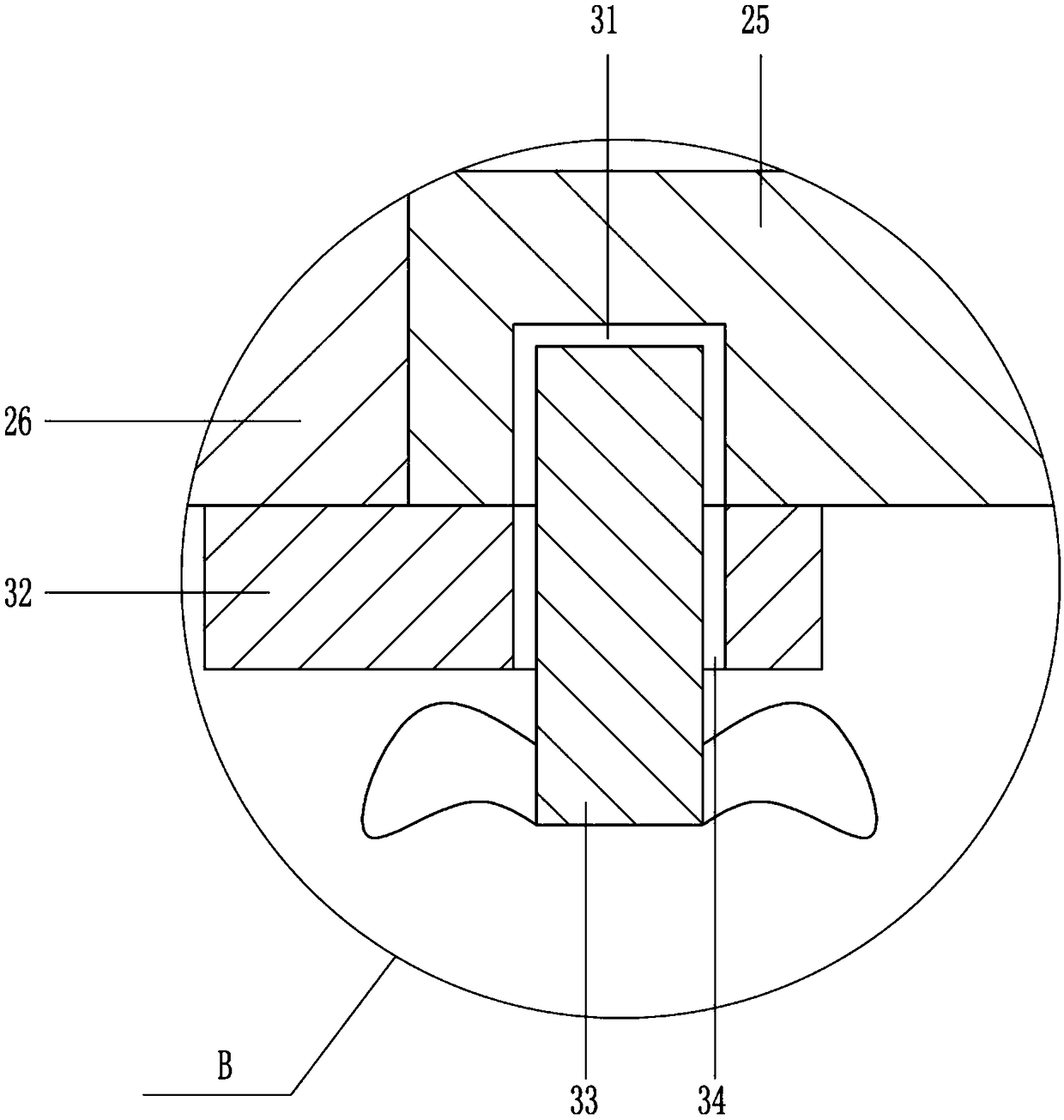

[0030] A high-efficiency crushing device for leather, such as Figure 1-10 As shown, it includes a bottom plate 1, a collection frame 2, a first mounting plate 3, a first connecting plate 4, a circular frame sleeve 5, a first rotating shaft 6, a first bearing seat 7, a second bearing seat 8, and a second rotating shaft 9. Circular side wall 10, first crushing blade 11, cover plate 13, second crushing blade 14, third bearing seat 15, first gear 16, second gear 17, third shaft 18, motor 19, second Mounting plate 20, third mounting plate 21, second connecting plate 22, third gear 23, fourth bearing housing 24, first baffle 25, second baffle 26, first butterfly bolt 28, first fixing block 29. The second fixing block 32 and the second butterfly bolt 33; the first mounting plate 3 is fixed on one side of the bottom plate 1, and the third mounting plate 21 is fixed on the other side of the bottom plate 1; close to the first mounting plate 3 The circular side wall 10 is affixed to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com