Press-fitting tool for inverted shoulder joint prosthesis

A press-fitting tool and shoulder joint technology, which is applied in the field of prosthesis, can solve the problems such as weak connection between the acetabular cup and the humerus, damage to the lining, fracture of the humerus, etc., and achieves the effects of easy popularization and application, safe and reliable use, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

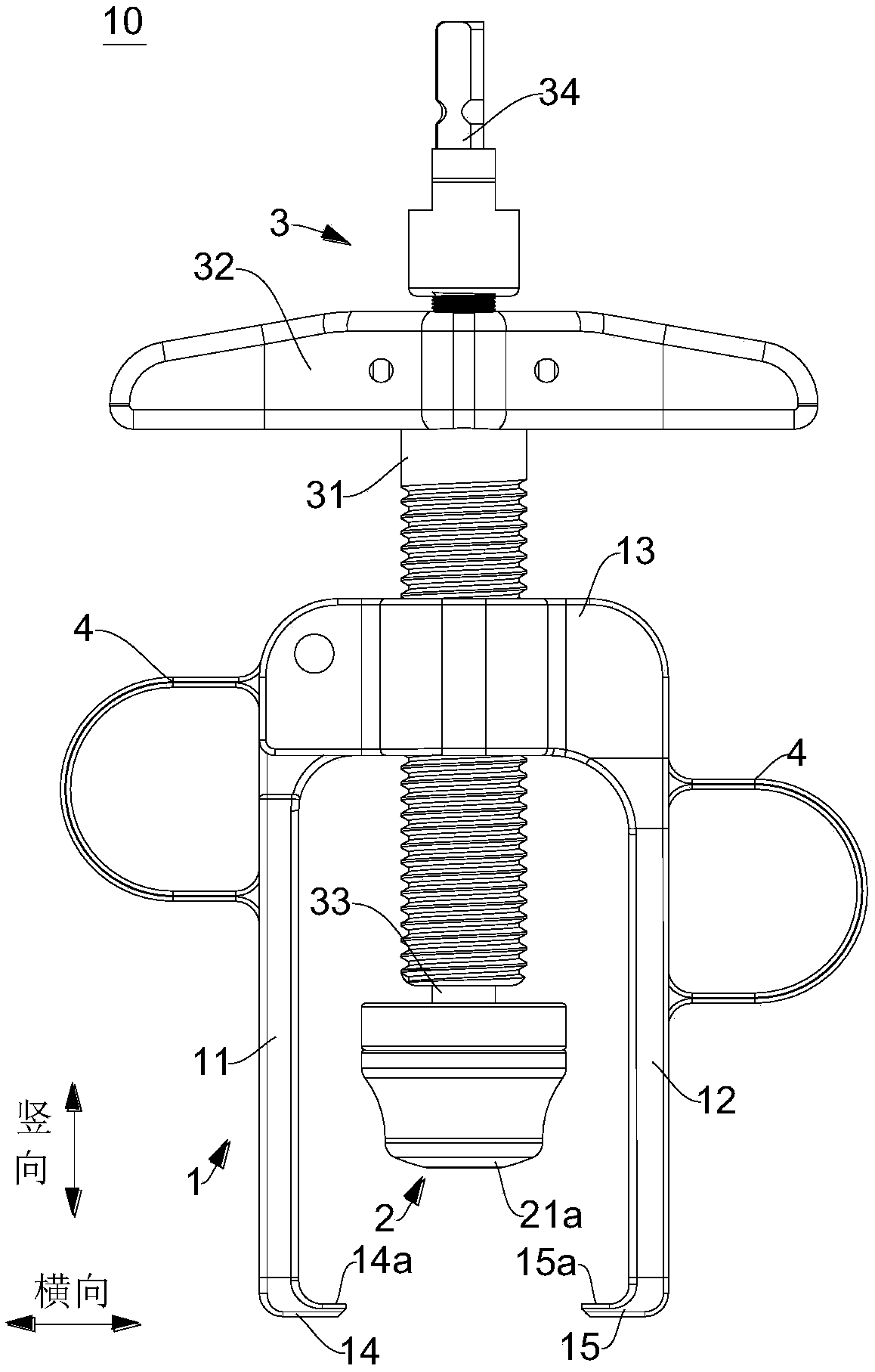

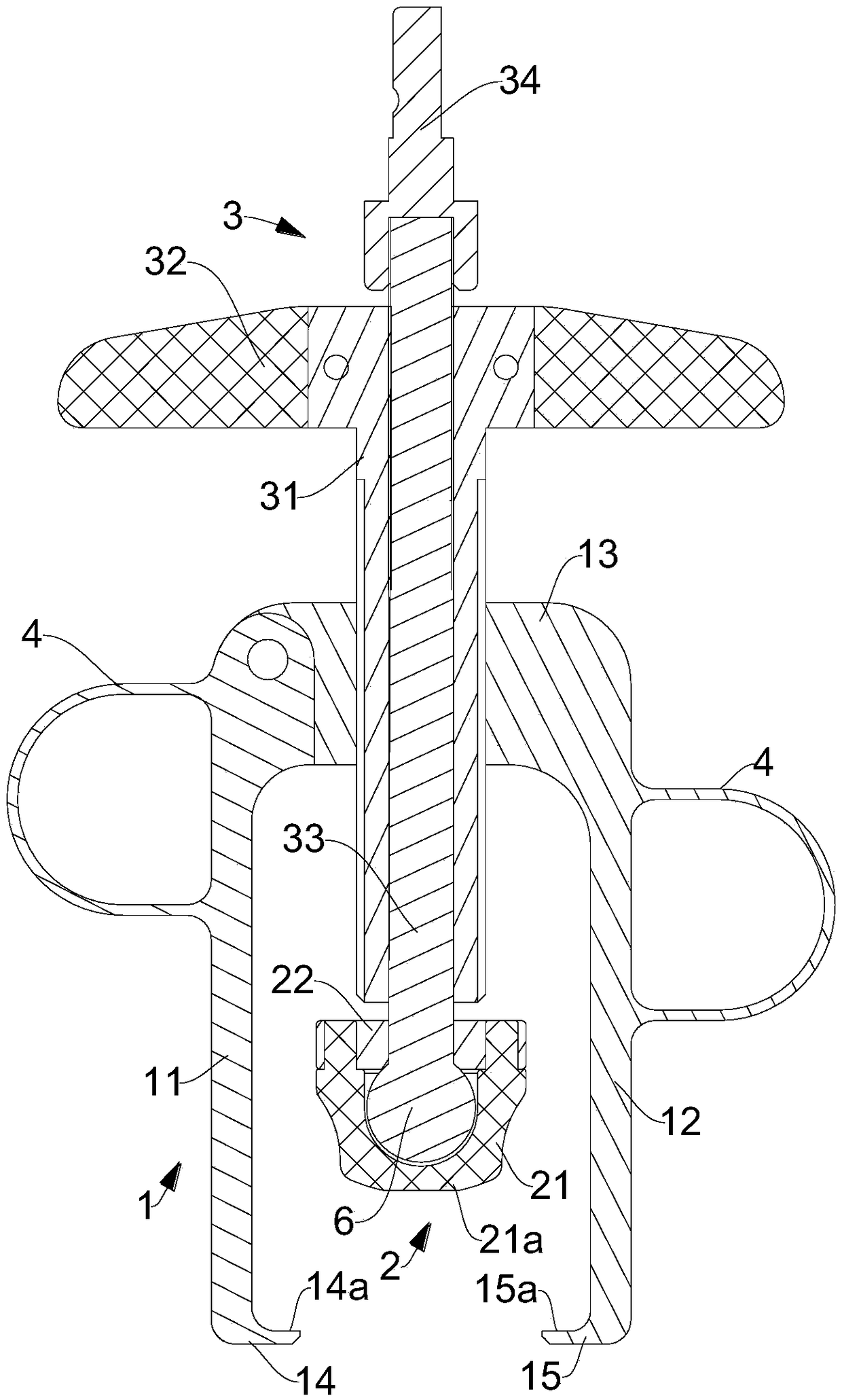

[0012] figure 1 It is a structural schematic diagram of a pressing tool for a reverse shoulder joint prosthesis according to an embodiment of the present invention; figure 2 It is a cross-sectional view of a pressing tool for a reverse shoulder joint prosthesis according to an embodiment of the present invention. Such as figure 1 and figure 2 As shown, the pressing tool 10 includes a bracket 1 capable of supporting the acetabular cup of a reverse shoulder joint prosthesis. The bracket 1 is usually constructed of a metallic material, preferably medical grade stainless steel (eg 05cr17ni4cu4nb). The bracket 1 specifically includes a crossbeam 13, a first vertical arm 11 and a second vertical arm 12, and a first bracket hook 14 provided on the bottom end of the first vertical arm 11 and a bottom hook provided on the bottom end of the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com