Pneumatic seed metering mechanism and pneumatic belt-sending precise seed metering apparatus

A kind of seeding mechanism and pneumatic technology, which is applied in the field of pneumatic belt-feeding precision seeding device, can solve the problems of high landing speed, poor hole formation of each hole, and easy bouncing, so as to reduce the seeding height and achieve high precision. Hole row seeding to ensure the effect of seeding number per hole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

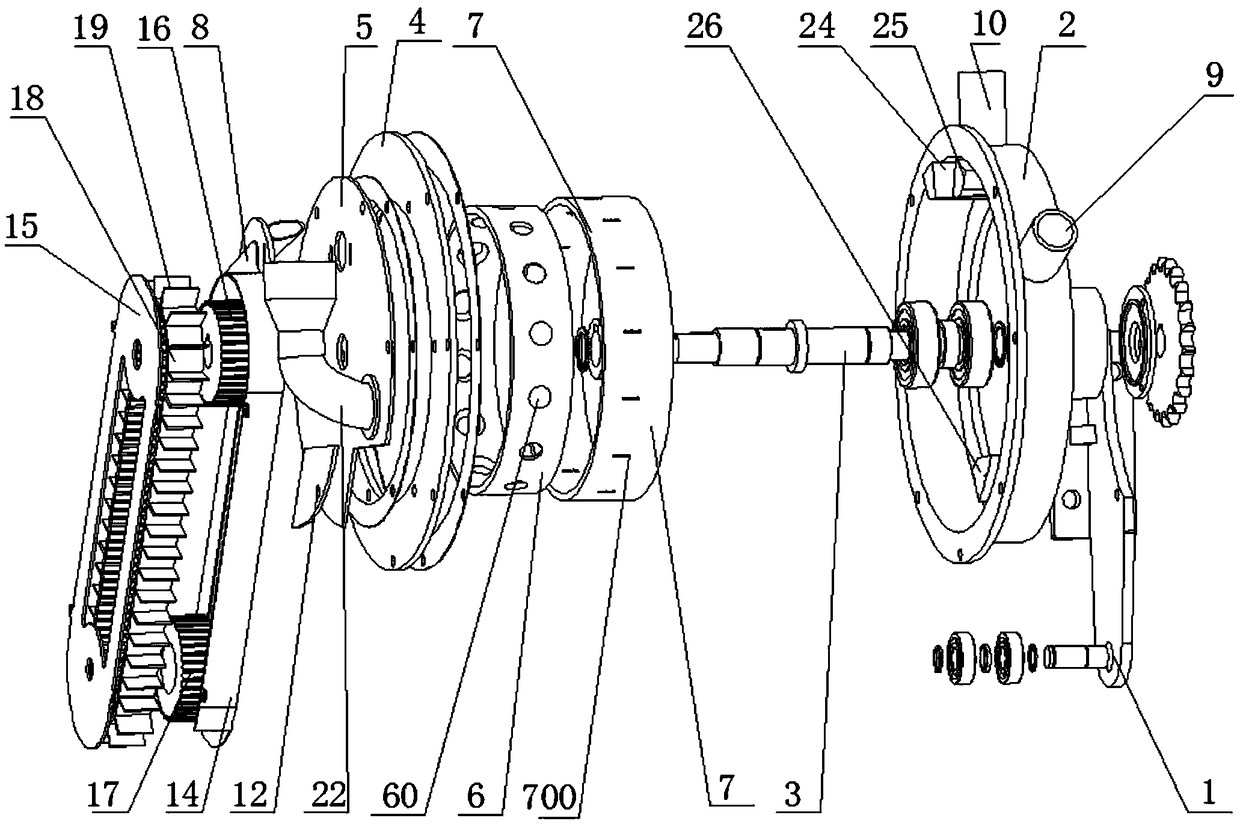

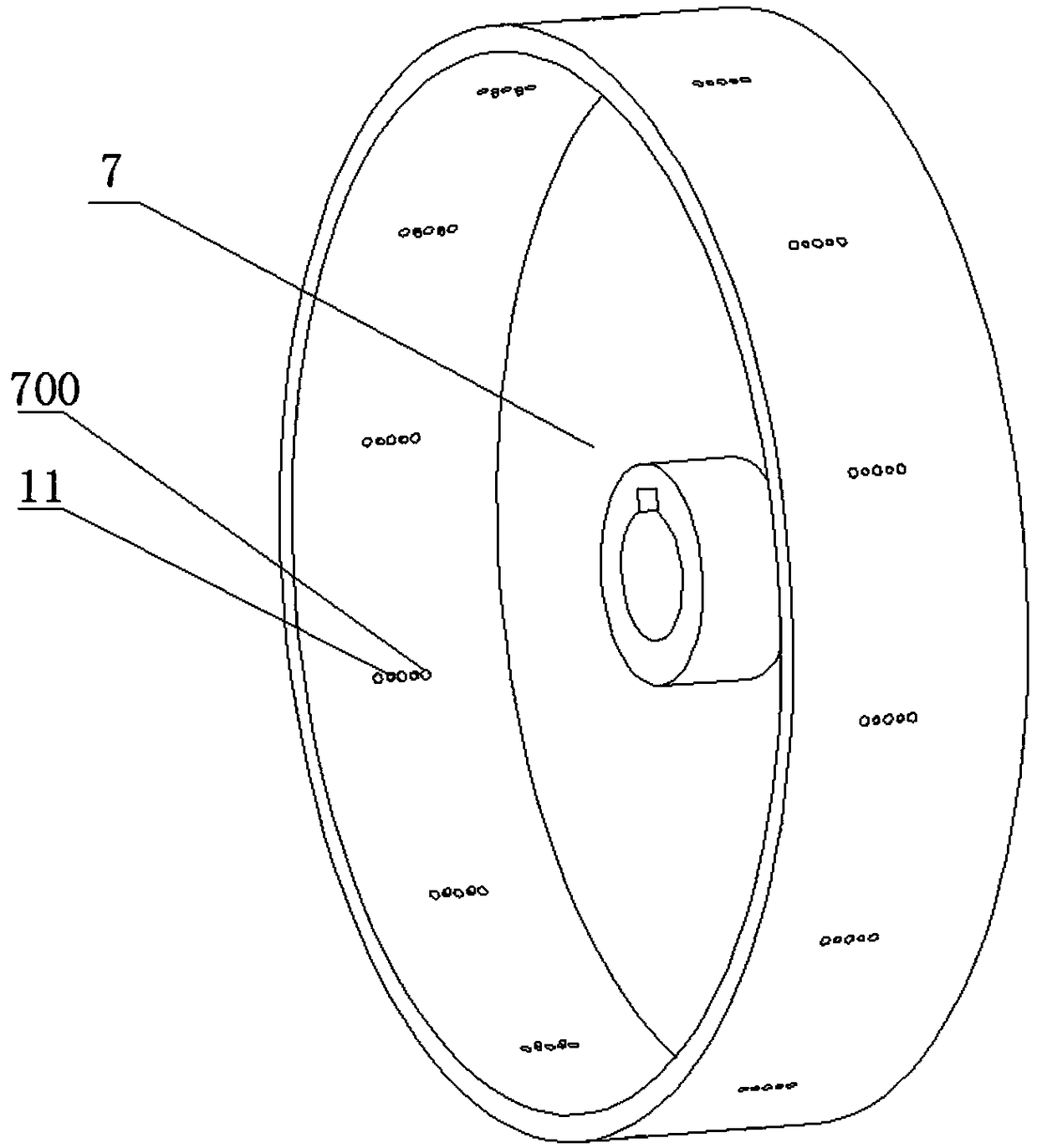

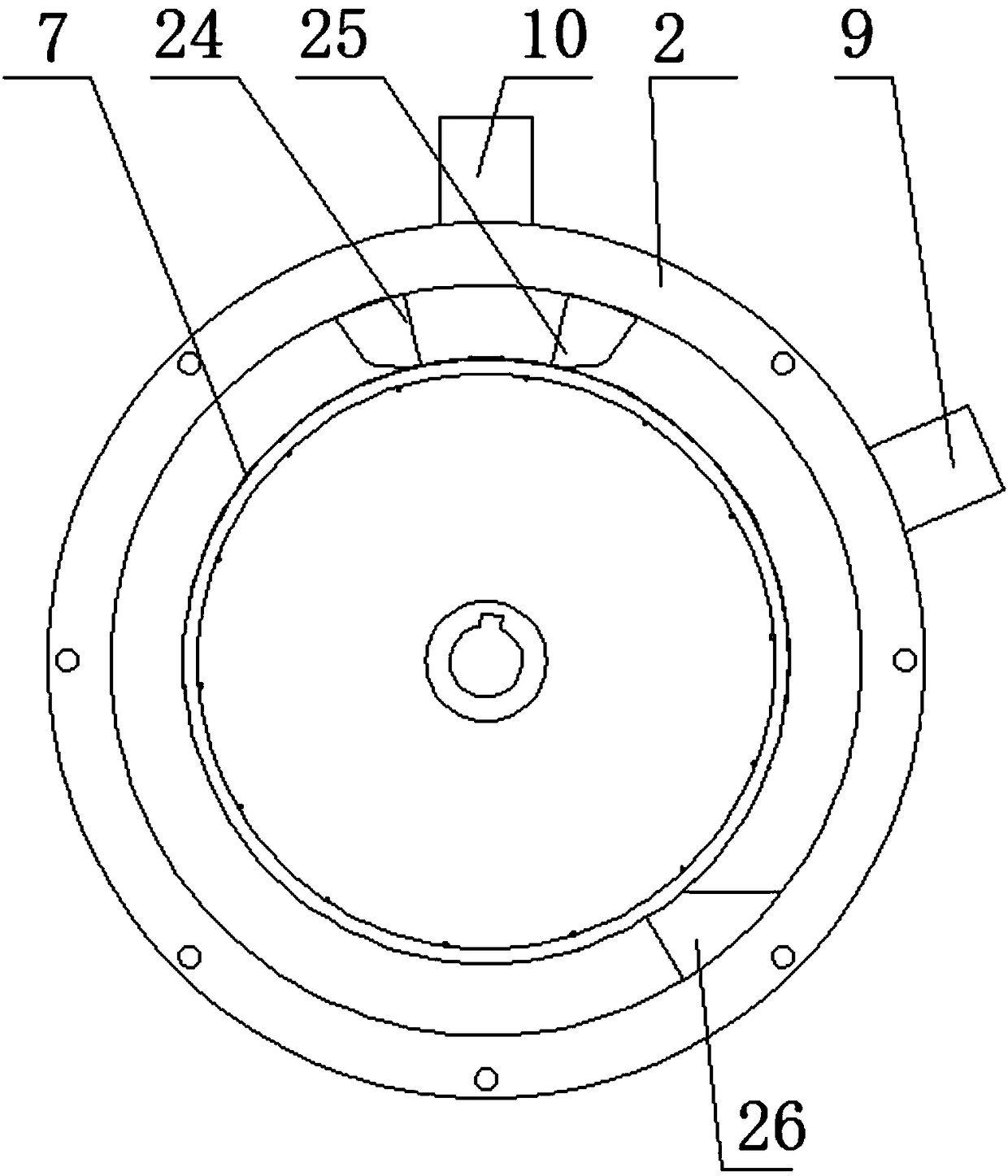

[0035] Such as Figure 1-4 As shown, a pneumatic seeding mechanism includes a casing 2, a transmission shaft 3, a sealing ring 4, a cover plate 5, a socket hole 6, a suction hole roller 7, a seed introduction pipe 8 and an air suction pipe 9;

[0036] The casing 2 is coaxially rotated and set on the transmission shaft 3. The casing 2 is connected to the transmission shaft 3 through bearings. The outer end surface of the casing 2 is provided with a bearing cover. The bearing cover is used for fixing and positioning the bearing. The sealing ring 4 is fixed by bolts. Installed on the end face of the housing 2, and a rubber sealing ring is provided between the sealing ring 4 and the housing 2 to ensure the sealing performance. There is a gasket, a cavity is formed between the shell 2, the sealing ring 4 and the cover plate 5, the socket hole 6 and the suction hole roller 7 are set in the cavity, the suction hole roller 7 is fixedly set on the transmission shaft 3, the socket hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com