Legume crop planting robot

A robot and crop technology, applied in planting methods, planter parts, agricultural machinery and implements, etc., can solve problems such as inability to guarantee seed quality, affect crop emergence rate, and insufficient seeds, so as to improve crop output and liberate labor , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

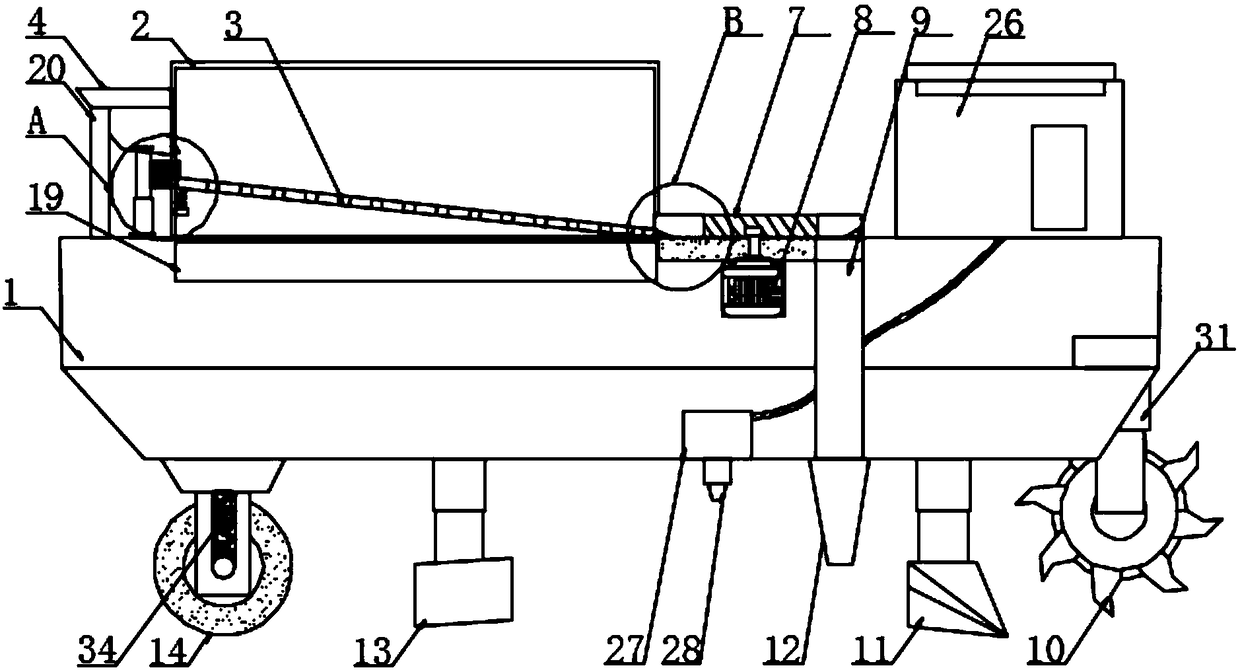

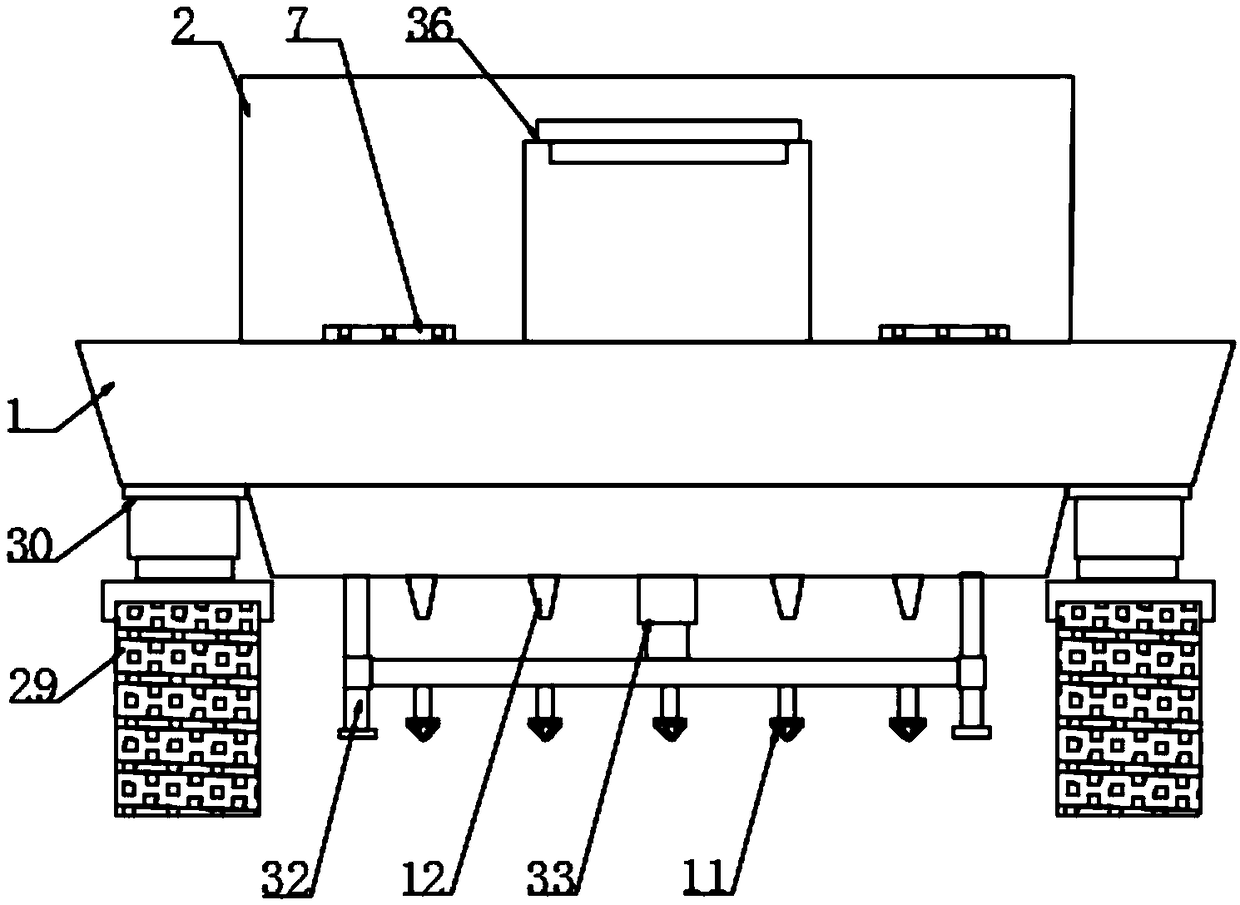

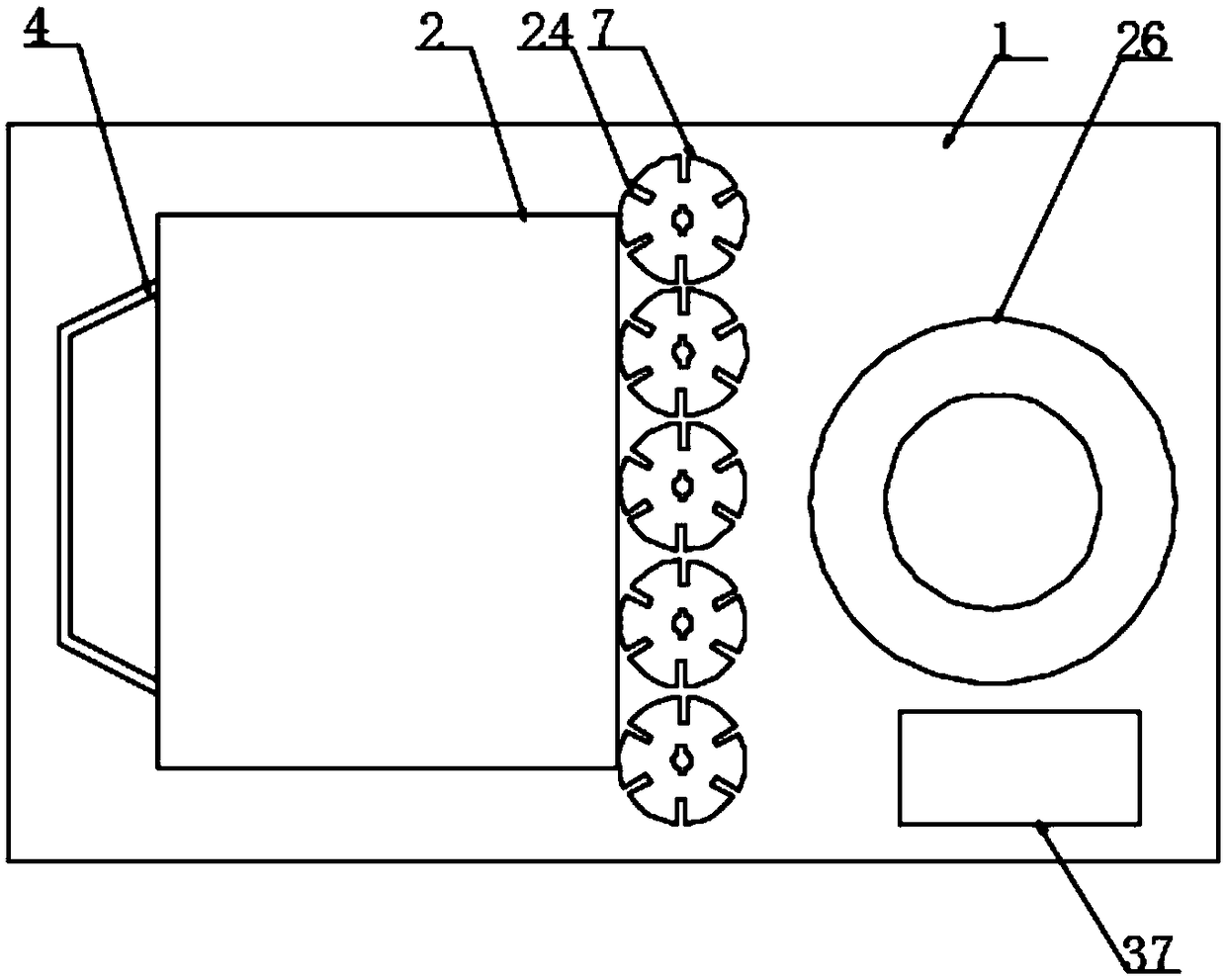

[0028] according to Figure 1-6 A kind of bean crop planting robot shown, comprises car body 1, and described car body 1 top is provided with screening device, and described screening device comprises housing 2, and described housing 2 is provided with sieve plate 3, and described A feed hopper 4 is provided on one side of the housing 2, a material inlet 5 is provided between the housing 2 and the feed hopper 4, and a discharge port 6 is provided on the other side of the housing 2. A sorting disc 7 is arranged outside the mouth 6, a first motor 8 is arranged inside the car body 1, the output shaft of the first motor 8 is connected to the sorting disc 7 in transmission, and a feeding channel is arranged at the bottom of the sorting disc 7 9. The sieve plate 3 is inclined, one end of the sieve plate 3 is hinged to the casing 2, the other end of the sieve plate 3 is set at the bottom of the material inlet 5, and a fixed block 15 is arranged inside the casing 2 A first spring 16 ...

Embodiment 2

[0031] The bottom of the car body 1 is provided with a turning plow 10, one side of the turning plow 10 is provided with a ditching knife 11, and one side of the ditching knife 11 is provided with a sowing port 12, and the feeding channel 9 is connected to the sowing port. 12, the sowing opening 12 side is provided with a pushing plate 13, and the pushing plate 13 side is provided with a pressing wheel 14, the ground plow 10 loosens and breaks up the ground, and the ditching knife 11 loosens the ground. Dig the planting groove on the surface of the land, and push the soil block to both sides of the planting groove, the seeds are discharged into the planting groove from the feeding channel 9 through the sowing port 12, and the pushing burying plate 13 backfills the soil mound on both sides of the planting groove to bury the seeds in the planting groove, Flattened by the pressure roller 14;

[0032] The bottom of the feed hopper 4 is inclined, the bottom of the feed hopper 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com