Grouting treatment method for strip mining goaf

A goaf and grouting technology, which is applied in mining equipment, earth square drilling, filling, etc., can solve problems such as difficult to grasp the long-term stability of striped coal pillars, imperfect technology, and difficult governance, and achieve a good society and economic value, the number of drilling holes is small, and the effect of easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

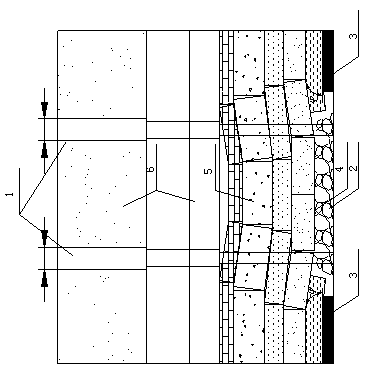

[0024] Accompanying drawing is a kind of specific embodiment of the present invention.

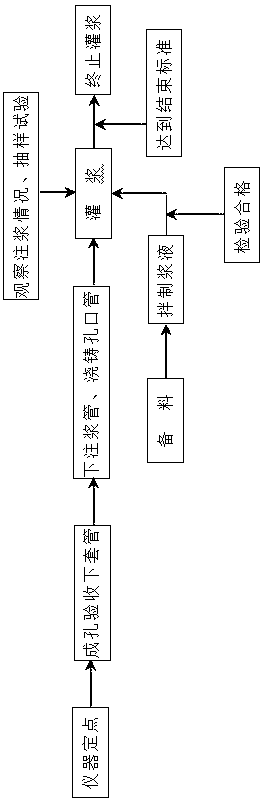

[0025] The strip mining goaf grouting treatment method of the present invention comprises the following steps:

[0026] Step 1: Borehole 1 location and layout planning: within the control range of the determined strip goaf 2 (the width of the goaf is generally 40m~80m) on the surface, the designed borehole 1 is located at the distance between both sides of the goaf 2 12m from the coal wall, arranged in double rows; drill holes 1 are arranged in groups of two, the distance between two holes in a group is 30m, and the distance between groups is 60m. The arrangement of the above-mentioned boreholes 1 avoids the dangerous areas of insufficient collapse and natural accumulation on the side of the coal wall and the long-term vulnerability of the coal wall to the erosion of mined-out water, and focuses on protecting the coal pillar, strengthening the plastically damaged area of the coal pillar,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com