Chain board turning machine

A technology of turning machine and chain plate, applied in the direction of conveyor, transportation and packaging, can solve the problems of breakage, continuous force of conveyor chain plate 13, increase the cost of chain plate replacement, etc. Easy to break effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

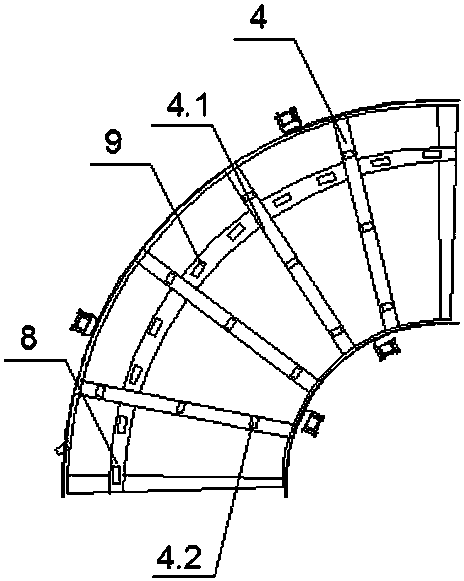

[0017] like Figure 1-5 As shown, the present invention includes an arc-shaped inner plate 1 and an outer plate 2, an annular conveyor chain plate 3 is arranged between the inner plate 1 and the outer plate 2, and a plurality of intervals are arranged below the conveyor chain plate 3 along the conveying direction. The idler device 4 includes a connecting pipe 4.1 connected between the inner plate 1 and the outer plate 2, and a plurality of first support bearings 4.2 arranged at intervals are installed on the connecting pipe 4.1.

[0018] The conveyor chain plate 3 is provided with a plurality of upper guide rails 5 for the support and guidance of the upper conveyor chain plate 3, and a plurality of lower guide rails 6 for the support and guidance of the lower conveyor chain plate 3. The upper guide rails 5 and the lower guide rails 6 are supported by intervals. The rod 8 is installed between the inner plate 1 and the outer plate 2, and the back of the conveying chain plate 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com