Full-automatic tissue packaging machine

A packaging machine, fully automatic technology, applied in the direction of paper product packaging, packaging, transportation packaging, etc., can solve the problems of occupying large workshop space, increasing labor costs, reducing packaging efficiency, etc., to save space, reduce labor costs, The effect of improving packaging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

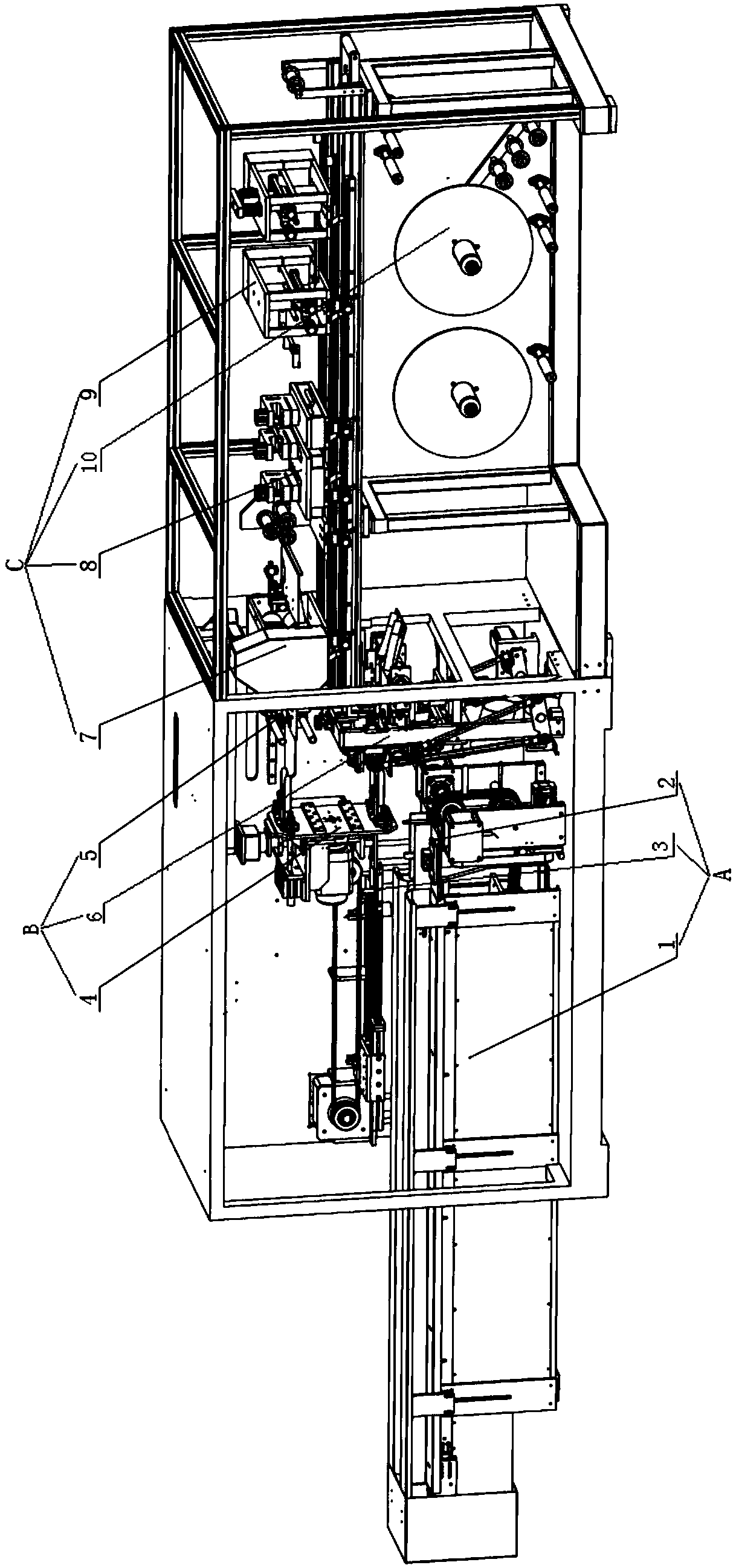

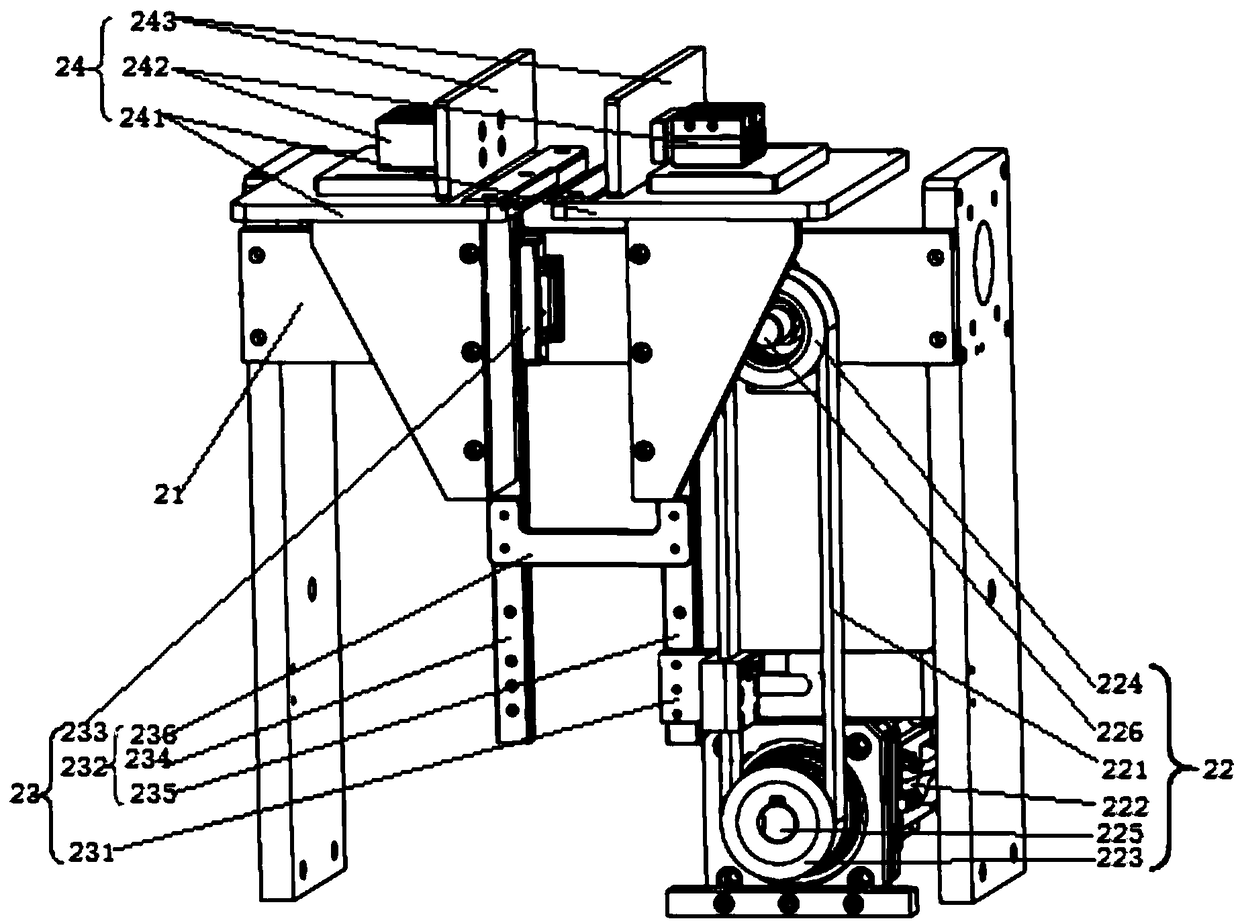

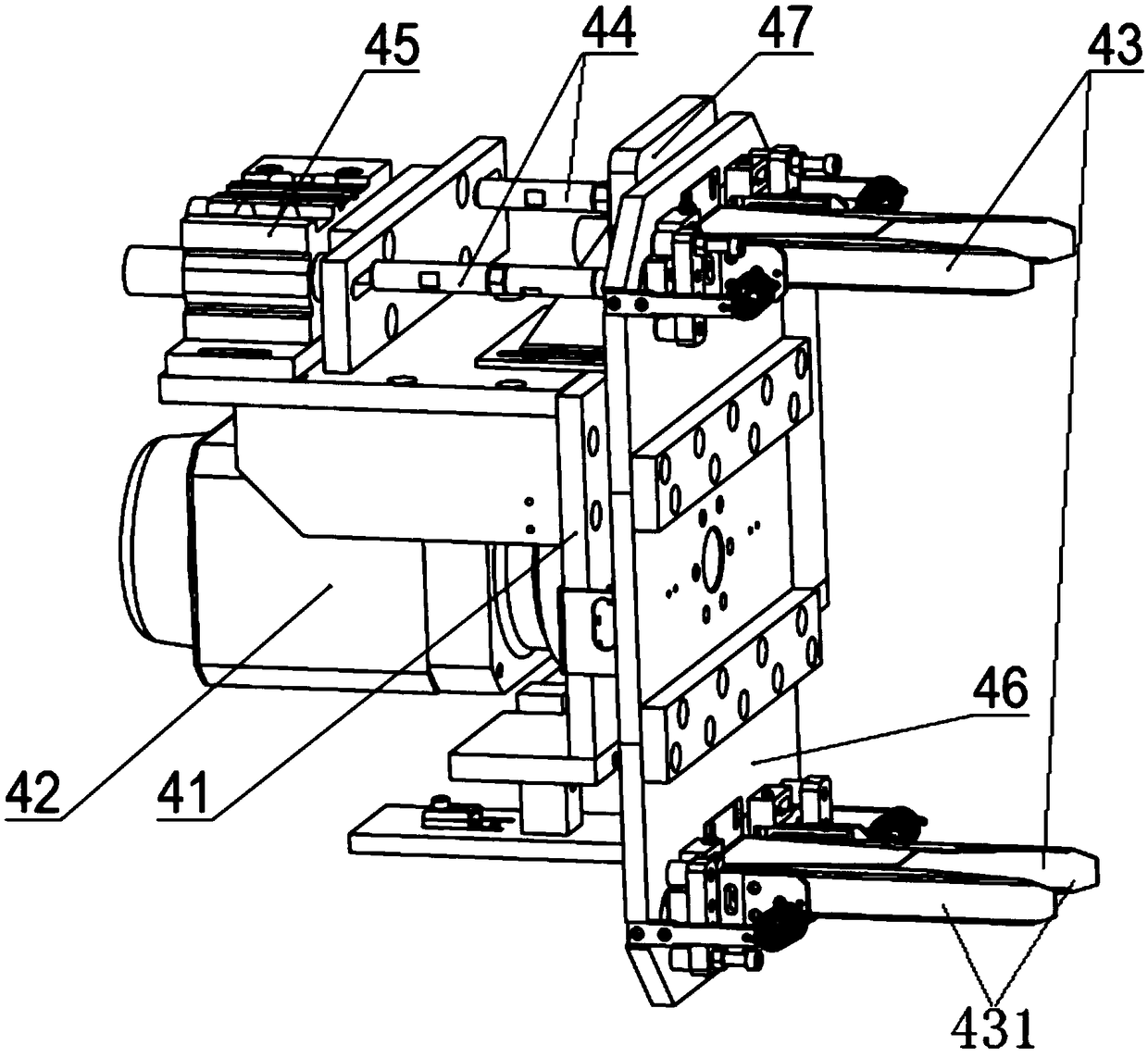

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0023] like Figure 1 to Figure 4 As shown, a fully automatic tissue packaging machine provided in this embodiment includes a feeding device A, a packaging forming device B, and a bag making device C. The outlet end of the feeding device A corresponds to the packaging inlet of the packaging forming device B , the bag-making device C transports the packaging bag between the outlet end of the feeding device A and the packaging inlet of the packaging forming device B. The feeding device A includes a material sorting mechanism 1, a material clamping mechanism 2, and a material pushing mechanism 3. The outlet end of the mechanism 1 corresponds to the inlet end of the clamping mechanism 2, the outlet end of the clamping mechanism 2 corresponds to the inlet end of the pushing mechanism 3, and the outlet en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com