Microswitch and test system

A technology of micro-switches and sleeves, applied in the direction of electric switches, contacts, electrical components, etc., can solve problems such as unfavorable manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The above-mentioned figures are only exemplary diagrams, and are only used to explain the present invention. Identical or functionally identical elements are provided with the same reference numerals throughout.

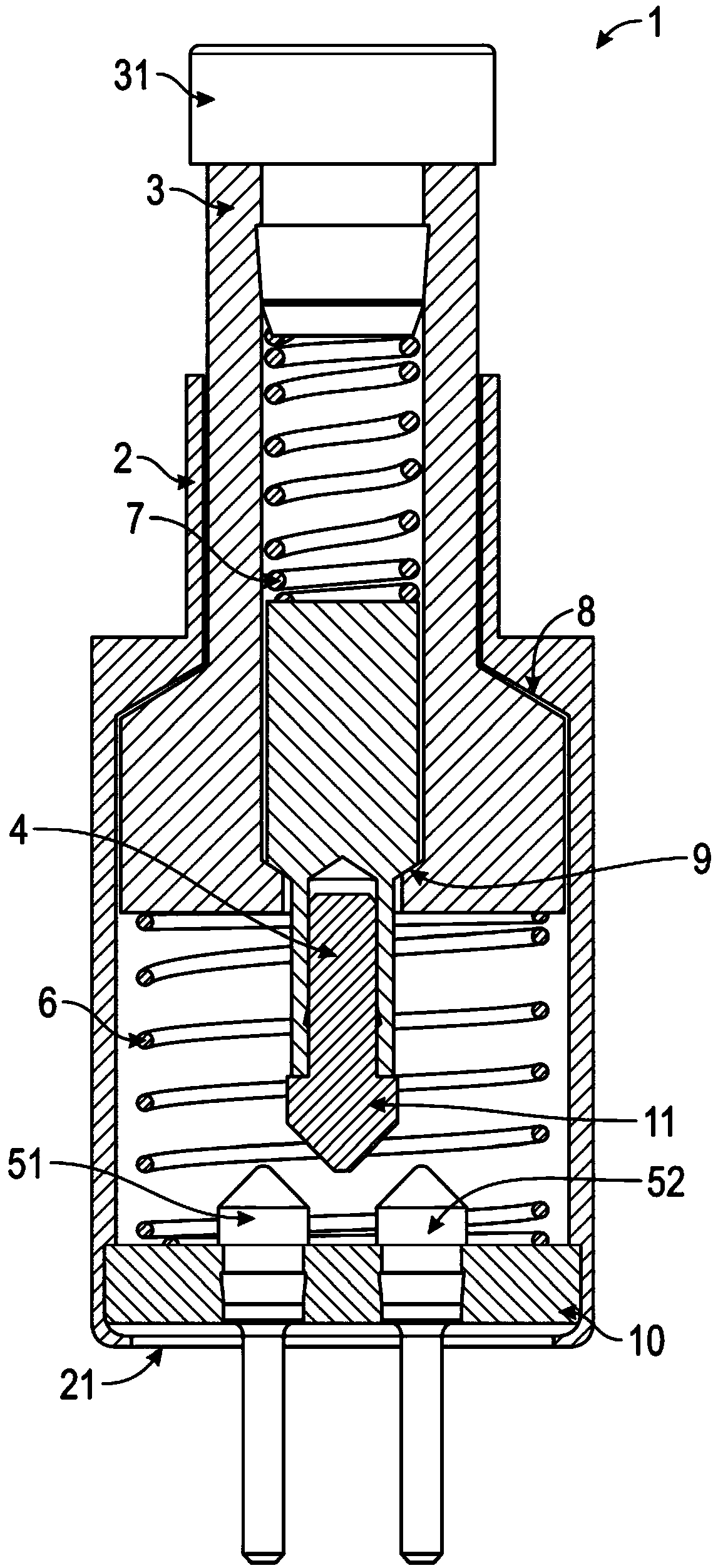

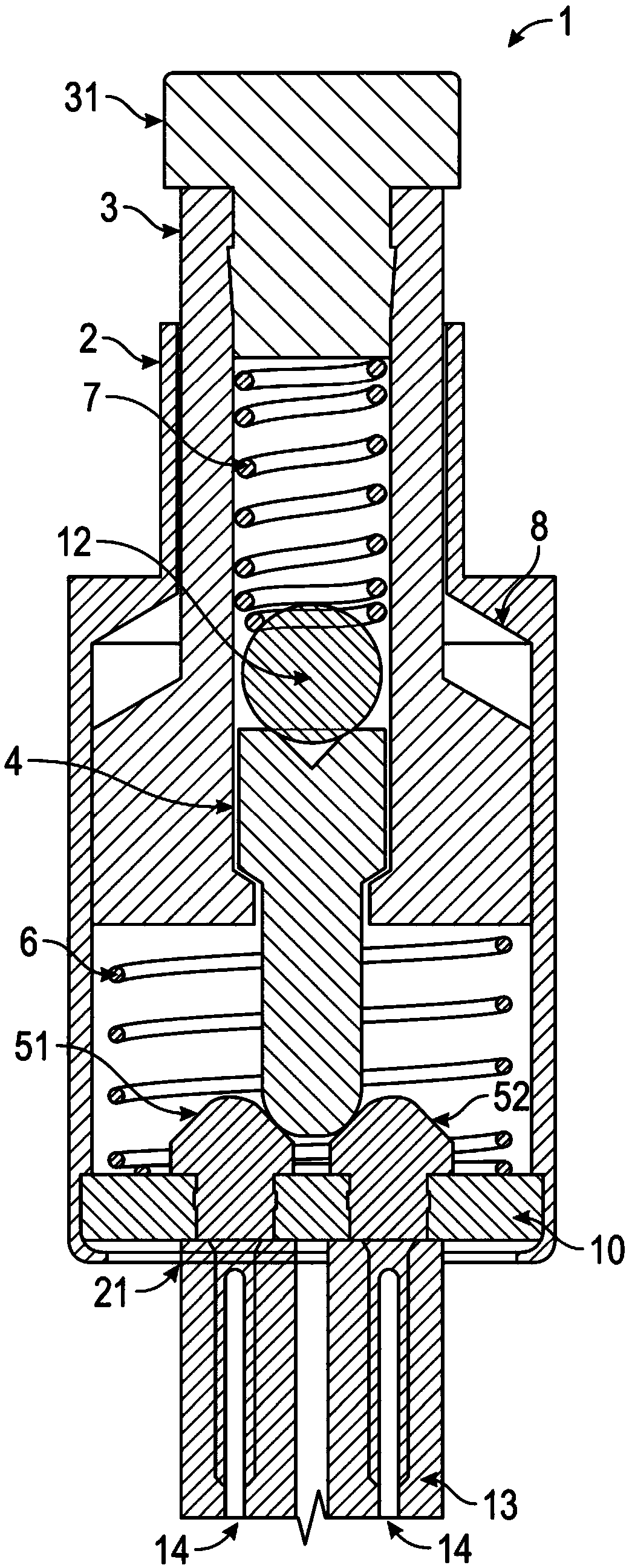

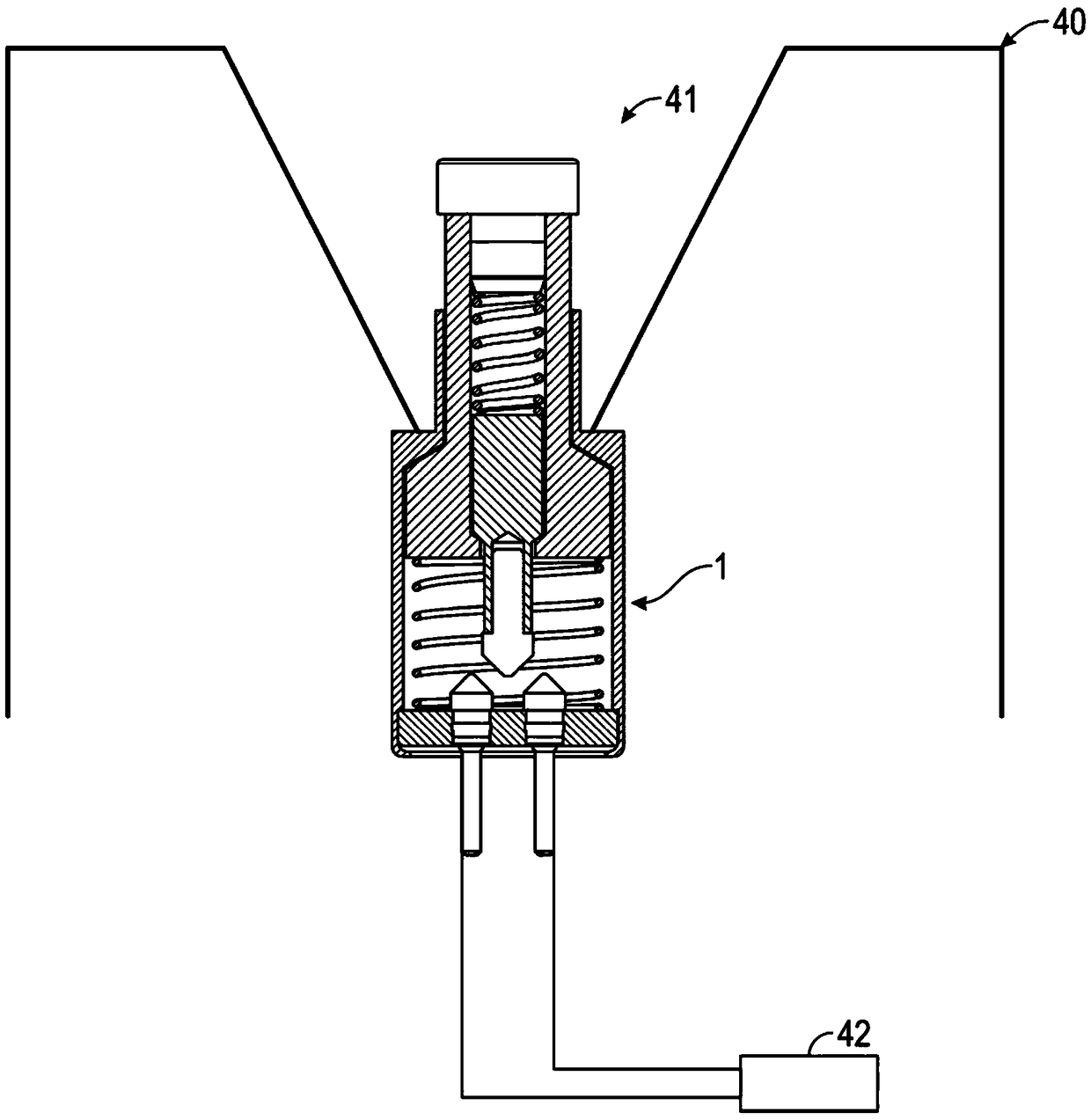

[0024] according to figure 1 The first microswitch 1 according to the invention comprises a cylindrical sleeve 2 with a narrowed and open neck from which a piston 3 protrudes. The piston 3 is also cylindrically shaped and is movably arranged in the sleeve 2 . There is only a small gap between the sleeve 2 and the piston 3 . The piston 3 can be pressed in the sleeve 2 in the direction of the sleeve bottom 21 , whereupon the piston 3 is separated from the sleeve 2 at a first inclined portion 8 open towards the sleeve bottom 21 which separates the sleeve 2 The neck is connected with a wide central base. When the piston 3 returns to the initial position due to the return spring 6 arranged at the sleeve bottom 21 or between the retaining plate 10 and the piston...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com