Quality online monitoring method based on dye cloth printing and dyeing process

A quality and dyeing technology, applied in the processing of textile materials, textiles and papermaking, instruments, etc., can solve the problems of uneven dyeing quality, fabric printing and dyeing failure, and disordered dyeing patterns, etc. The effect of eliminating hysteresis and reducing the rate of defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

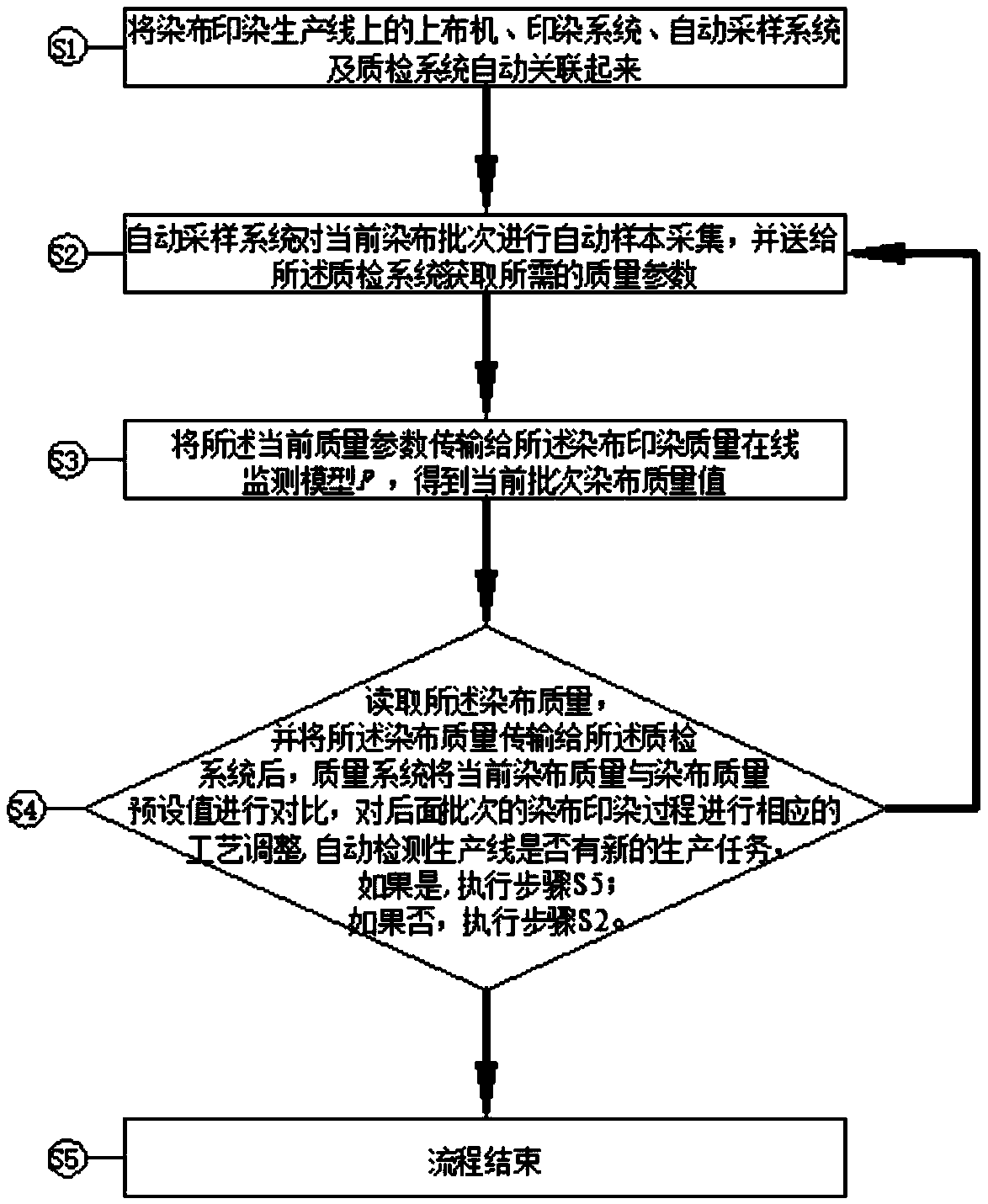

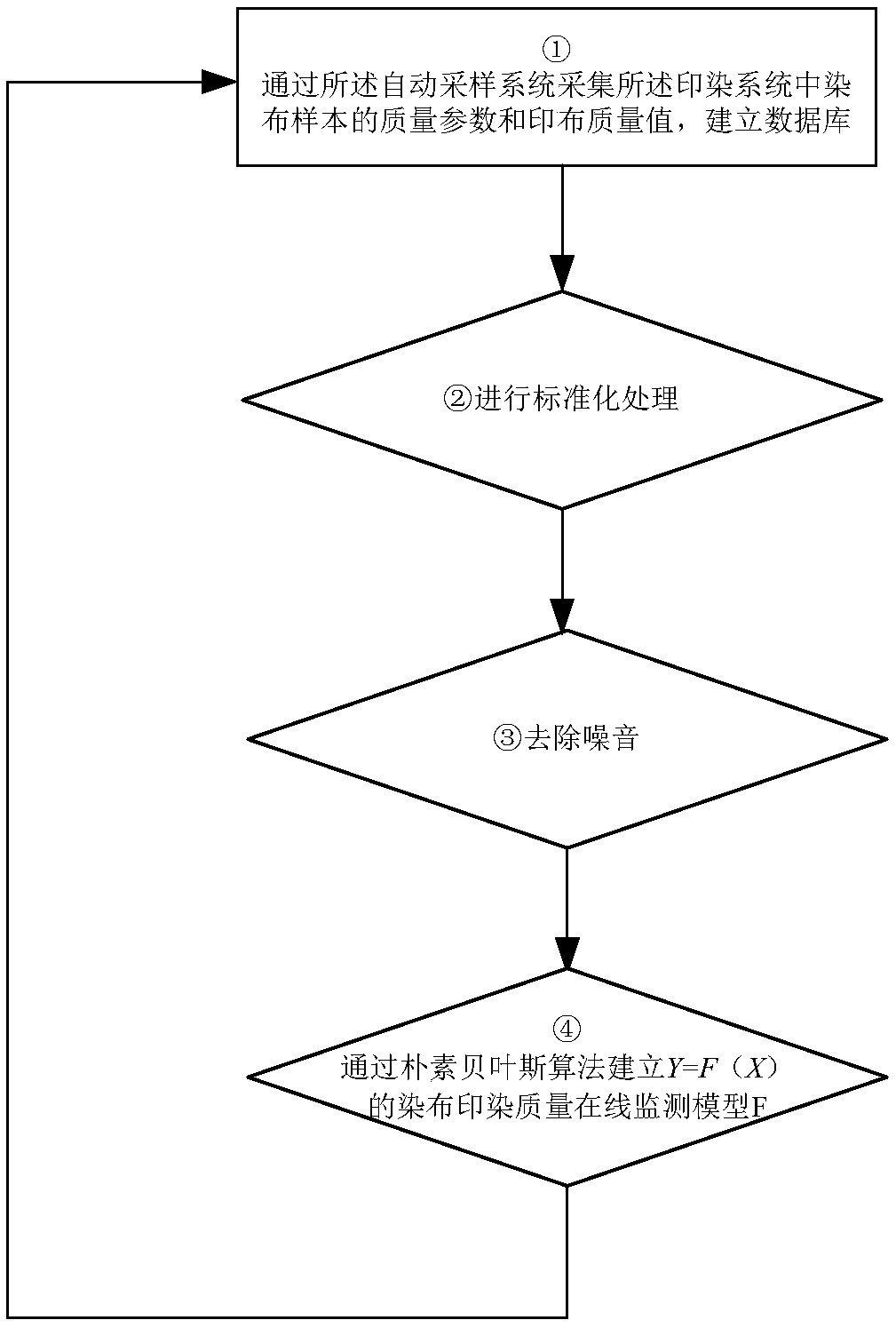

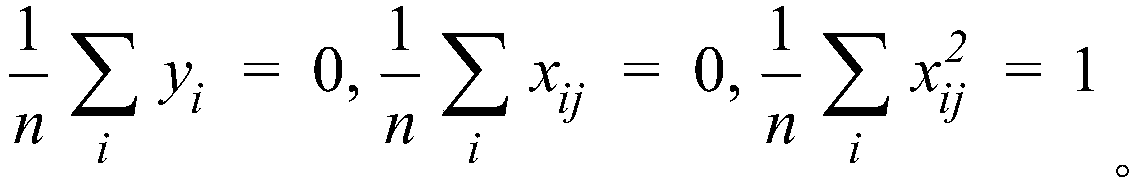

[0035] see figure 1 and figure 2 A preferred embodiment of an online quality monitoring method based on the dyeing process of dyed cloth provided by the present invention is as follows.

[0036] Dyeing and dyeing of cloth is an important process in the production process of cloth, and it is an important quality indicator for evaluating cloth. Through appropriate measurement methods, image data of dyed cloth samples can be obtained, and an online quality monitoring model for the dyeing and printing process can be established, which can be greatly improved. The lag time of monitoring is shortened, so that unqualified products can be found in time and the loss of the facto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com