High-speed moving body microbubble drag reduction structure in water

A moving body, micro-bubble technology, applied in the direction of hydrodynamic characteristics/hydrostatic characteristics, hull, hull design, etc., can solve the problems of easy instability, difficult to maintain stability, limited wet area, etc. Guarantee the effect of good hydrodynamic characteristics and good maneuverability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing;

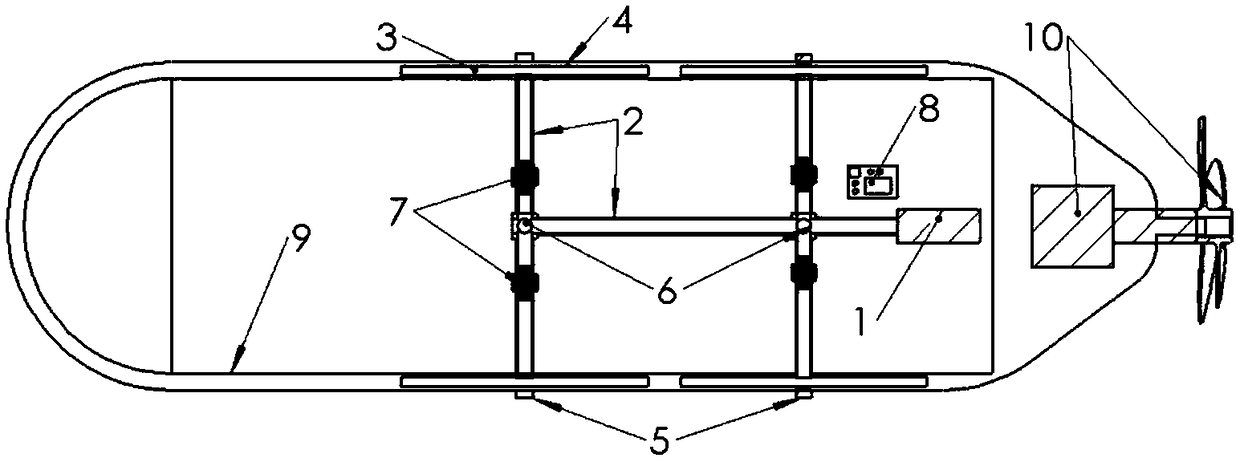

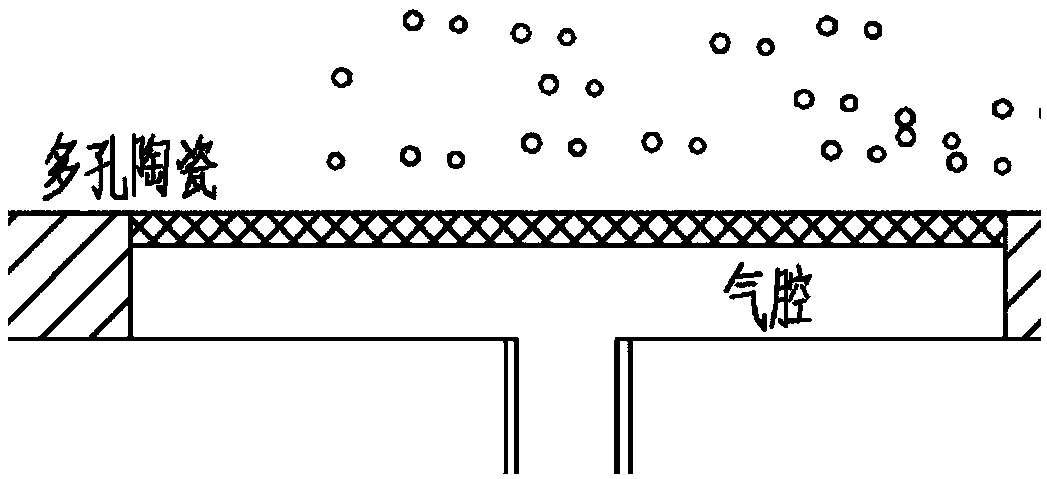

[0014] as attached figure 1 Shown, is porous ceramic diagram of the present invention, appended figure 2 It is a structural diagram of the present invention; image 3 It is a detailed diagram of the present invention; a microbubble drag reduction structure of a high-speed moving body in water, including an air pump 1, an air supply pipeline 2, an air cavity 3, porous ceramics 4, a multifunctional sensor 5, an electronic pressure regulating valve 6, and an electronic flowmeter 7 , the control equipment 8, the navigation body 9, and the power unit 10; the overall structure is symmetrical, the power unit 10 is located at the tail of the navigation body, and other devices are located inside the navigation body. There is an electronic pressure regulating valve 6 and an electronic flowmeter 7, the air chamber 3 is in close contact with the porous ceramic 4, and there is a mult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com