Dust retrograde preventable type sand making machine

A technology of sand making machine and body, applied in grain processing and other directions, can solve problems such as environmental pollution and affect the health of workers, and achieve the effects of eliminating dust, improving environmental quality, and preventing physical health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

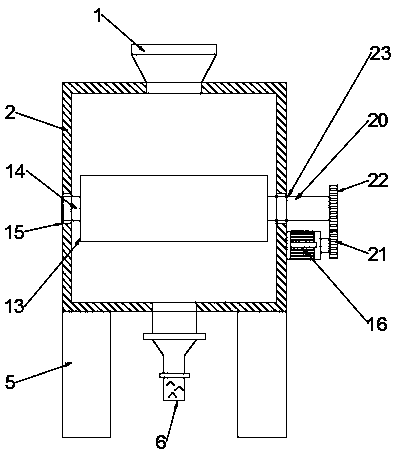

[0021] see Figure 1-2 , a dust-proof reversible sand making machine, including a body 2, a feed hopper 1 arranged at the top of the body 2 and a discharge port 11 at the bottom of the body 2, a crushing mechanism is provided inside the body 2, and the crushing mechanism is used to crush the The raw material is broken, and the bottom of the discharge port 11 is connected to the discharge funnel 9 through the connection sleeve 10, and the end of the discharge funnel 9 away from the connection sleeve 10 is connected to the discharge pipe 6 through the connection sleeve 18, and the inner wall of the discharge pipe 6 A baffle 7 is provided, and the baffle 7 is V-shaped, and the included angle of the V is 90-120 degrees. By setting the baffle 7, the dust can be prevented from retrograde, causing secondary dust; A closed chamber is formed between the material hopper 9 and the outlets 11 and 6, which can effectively eliminate the dust generated during crushing and material transporta...

Embodiment 2

[0029] see image 3 , Embodiment 2 Compared with Embodiment 1, the end of the rotating shaft 20 away from the crushing roller 13 is connected to the driven gear 22, the output shaft of the drive motor 16 is connected to the drive gear 21, and the driven gear 22 meshes with the drive gear 21. The driving motor 16 drives the driving gear 21 to rotate, the driven gear 22 is driven to rotate by the meshing of the driven gear 22 and the driving gear 21, and then the crushing roller 13 and the blow bar 12 on the crushing roller 13 are driven to rotate through the second rotating shaft 20, and the raw material is crushed. broken.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com