A kind of grease jelly jelly and preparation method thereof

A technology for oil gel and soft candy, applied in confectionery, confectionery industry, food science and other directions, can solve the problems of liquid oil loss, three-dimensional network structure damage, unpleasant smell and so on, achieve smooth printing, good taste, oil-carrying high volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

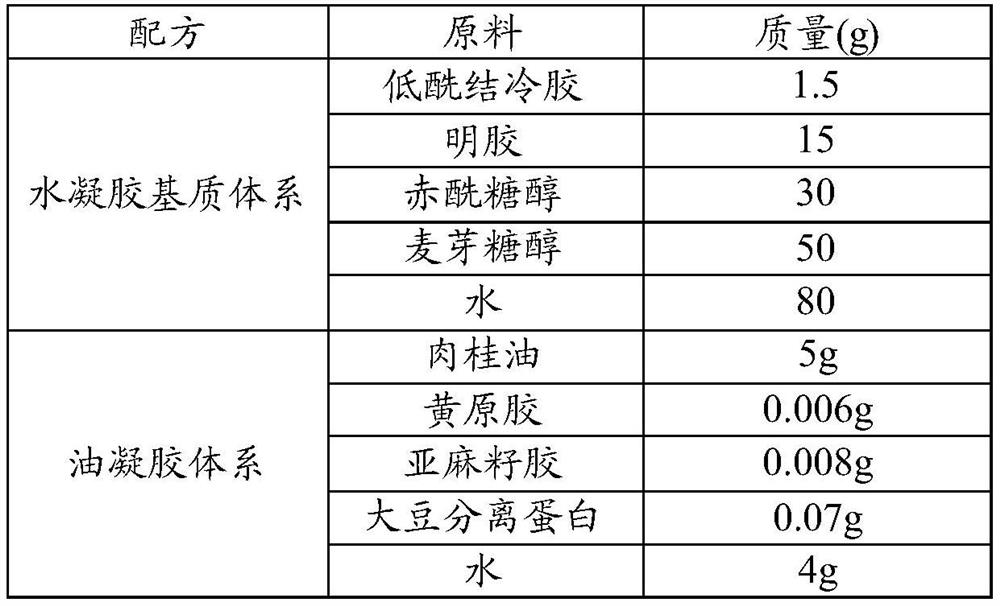

Embodiment 1

[0042]

[0043] Preparation:

[0044] (A) Disperse 1.5g of low-acyl gellan gum and 15g of gelatin in deionized water sequentially in a water bath at 80°C to obtain a composite glue dispersion; disperse 30g of erythritol into 50g of liquid maltitol in an oil bath at 105°C After being uniformly dispersed, the sugar alcohol liquid is obtained; the composite glue dispersion liquid is added to the sugar alcohol liquid to boil sugar and remove water to form a hydrogel matrix;

[0045] (B) Take 0.04g of soybean protein isolate, 0.008g of linseed gum, and 0.006g of xanthan gum and disperse them in 5g of deionized water in a water bath at 70°C to form a uniform dispersion, then weigh 5g of cinnamon oil and slowly drop it within 5min. Add it to the dispersion liquid, and after the oil is evenly dispersed, place it in a high-shear machine and cut it for 5 minutes. After cooling, it will form an immobile soft solid oil gel.

[0046] (C) The oil gel loaded with 5 g of cinnamon oil was ...

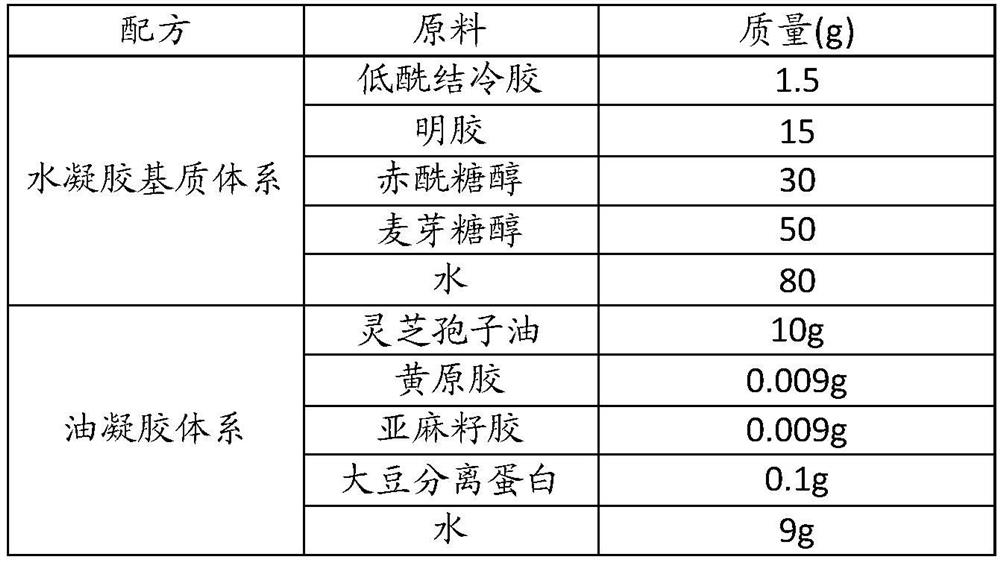

Embodiment 2

[0051]

[0052] Preparation:

[0053] (A) Take 1.5g of low-acyl gellan gum and 15g of gelatin and disperse them into 80g of deionized water successively in a water bath at 80°C to obtain a composite glue dispersion; disperse 30g of erythritol into 50g of liquid maltitol in an oil bath at 105°C In the process, the sugar alcohol liquid is obtained after the dispersion is uniform; the composite glue dispersion liquid is added to the sugar alcohol liquid and boiled to remove water to form a hydrogel matrix;

[0054] (B) Take 0.1g of soybean protein isolate, 0.009g of linseed gum, and 0.009g of xanthan gum and disperse them in 9g of deionized water successively in a 70°C water bath to form a uniform dispersion, then weigh 10g of Ganoderma lucidum spore oil and slowly Add it dropwise to the dispersion, and after the oil is evenly dispersed, place it in a high-shear machine at gear A and cut for 5 minutes, and form an immobile soft solid oil gel after cooling.

[0055] (C) The oi...

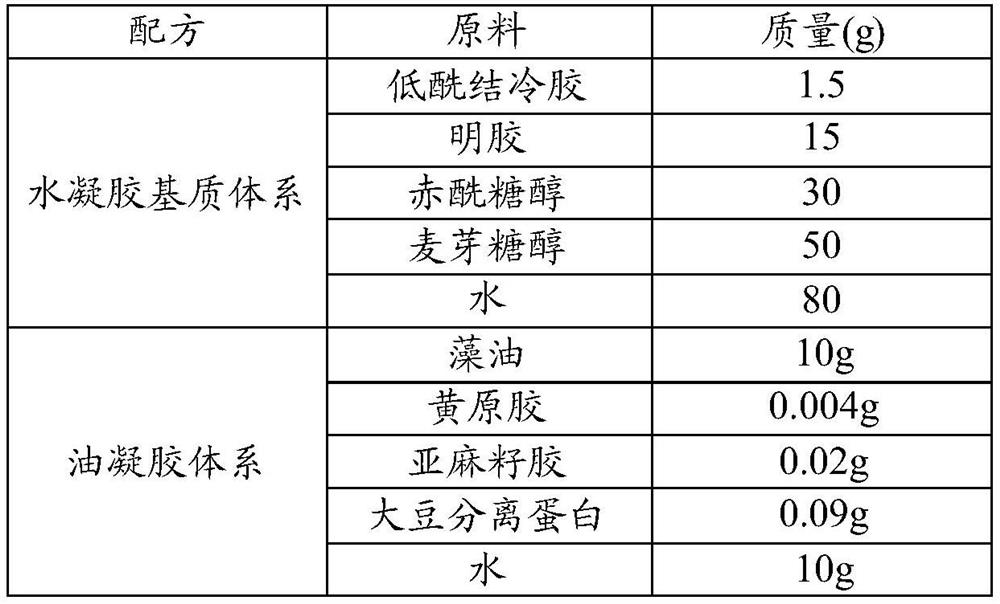

Embodiment 3

[0058]

[0059] Preparation:

[0060] (A) Disperse 1.5g of low-acyl gellan gum and 15g of gelatin in 80g of deionized water sequentially in a water bath at 80°C to obtain a composite glue dispersion; disperse 30g of erythritol into 50g of liquid maltitol in an oil bath of 105°C In the process, the sugar alcohol liquid is obtained after the dispersion is uniform; the composite glue dispersion liquid is added to the sugar alcohol liquid and boiled to remove water to form a hydrogel matrix;

[0061] (B) Take 0.09g of soybean protein isolate, 0.02g of linseed gum, and 0.004g of xanthan gum and disperse them in 10g of deionized water in a water bath at 70°C to form a uniform dispersion, then weigh 10g of algae oil and drop it slowly within 5 minutes Add it to the dispersion liquid, and after the oil is evenly dispersed, place it in a high-shear machine and cut it for 5 minutes. After cooling, it will form an immobile soft solid oil gel.

[0062] (C) The oil gel loaded with 10 g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com