Double-pressure control proportional valve and control method

A proportional valve and dual pressure technology, applied in the field of dual pressure control proportional valve and control, can solve the problems of insensitive output pressure and poor voltage stabilization effect, and achieve a simple and practical structure, good voltage stabilization effect, and sensitive output pressure adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

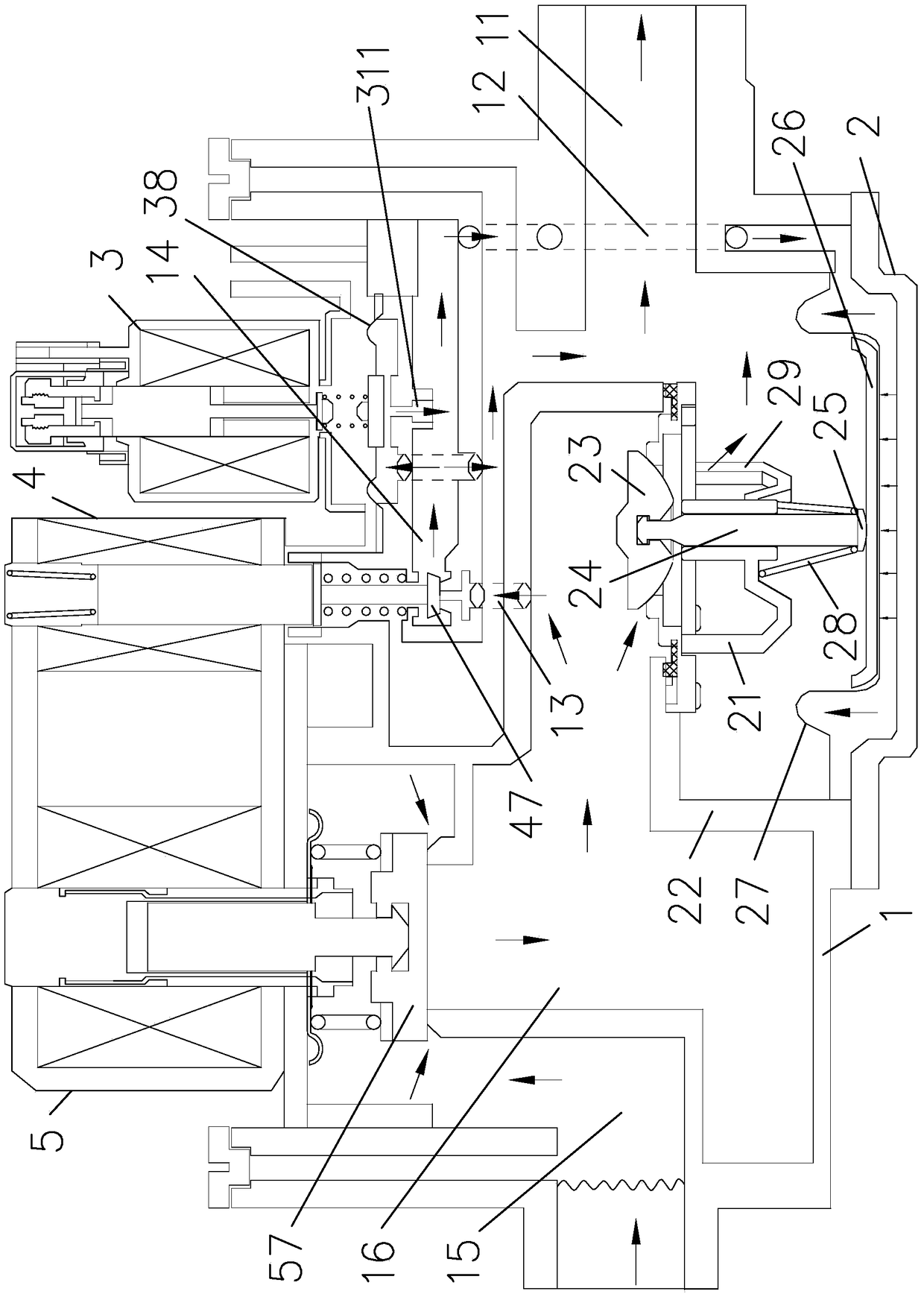

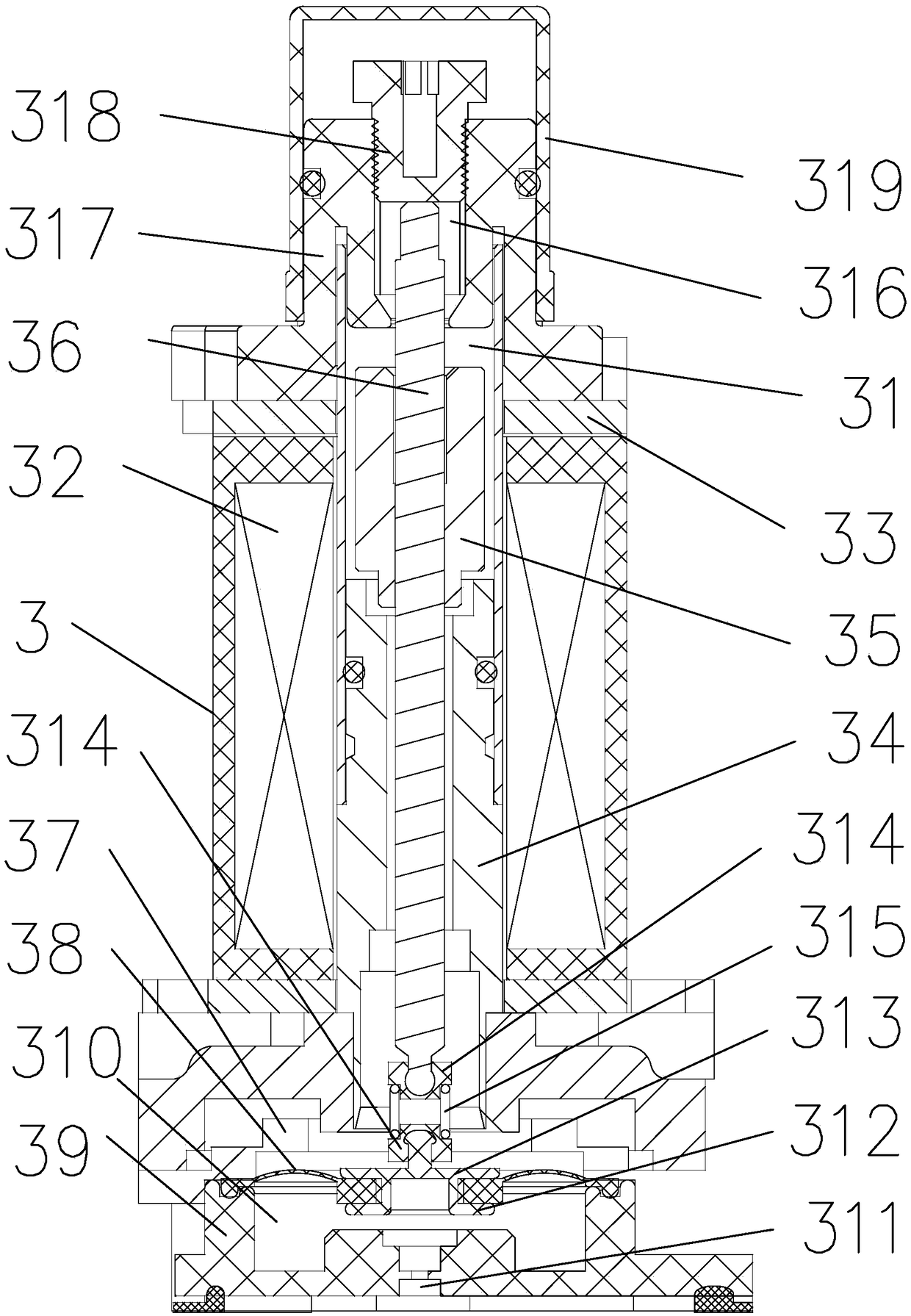

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

[0017] as attached figure 1 , attached figure 2 , attached image 3Shown: a dual pressure control proportional valve, including: a main valve body 1 with a main inlet and a main outlet 11, a main proportional valve 2, and a servo proportional valve 3; the main proportional valve 2 includes: an upper end and a The main proportional valve body 22 of the spacer 21 communicated with the main air inlet is penetrated in the spacer 21 and the upper end is provided with the main proportional valve core 24 of the main proportional block 23 opposite to the upper end of the spacer 21, and the main proportional valve The lower end of the core 24 integrally constitutes a connected compression spring seat 25, which is provided with a supporting plate 26 opposite to the lower end of the compression spring seat 25 and a main proportional film 27 whose outer edge is bonded to the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com