Oil scraping device of petroleum engineering oil production well and using method thereof

A technology of oil scraping device and petroleum engineering, which is used in earth-moving drilling, wellbore/well components, cleaning appliances, etc., can solve the problems of fixed block not being pushed, no buffer device or return action mechanism, caking, etc. Achieve the effect of improving mud scraping efficiency and overcoming motor lockup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

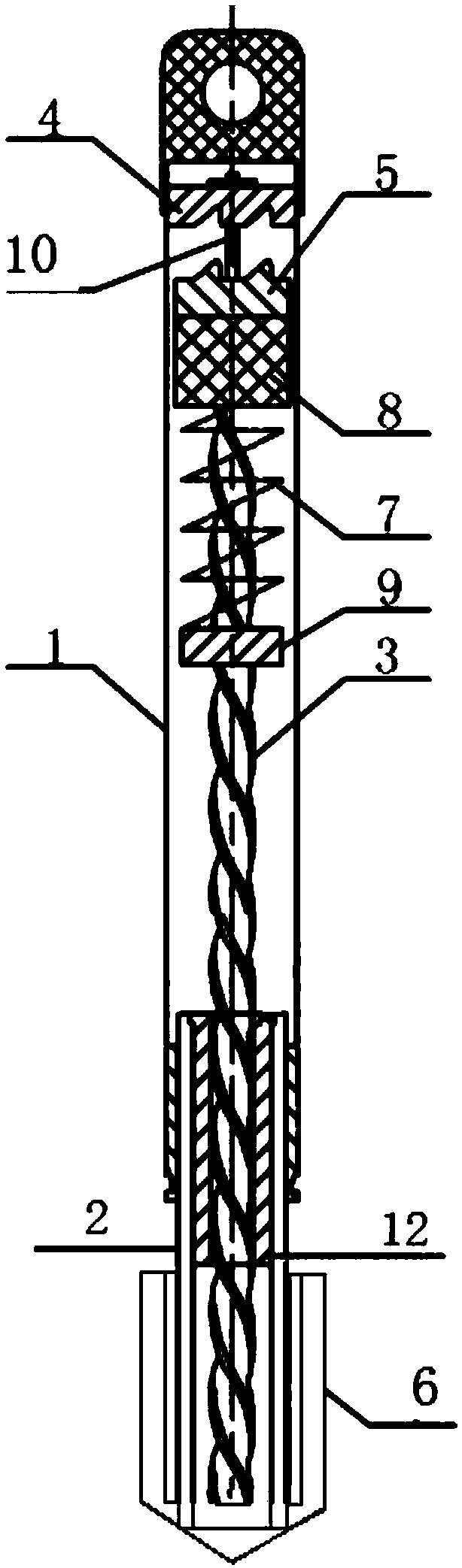

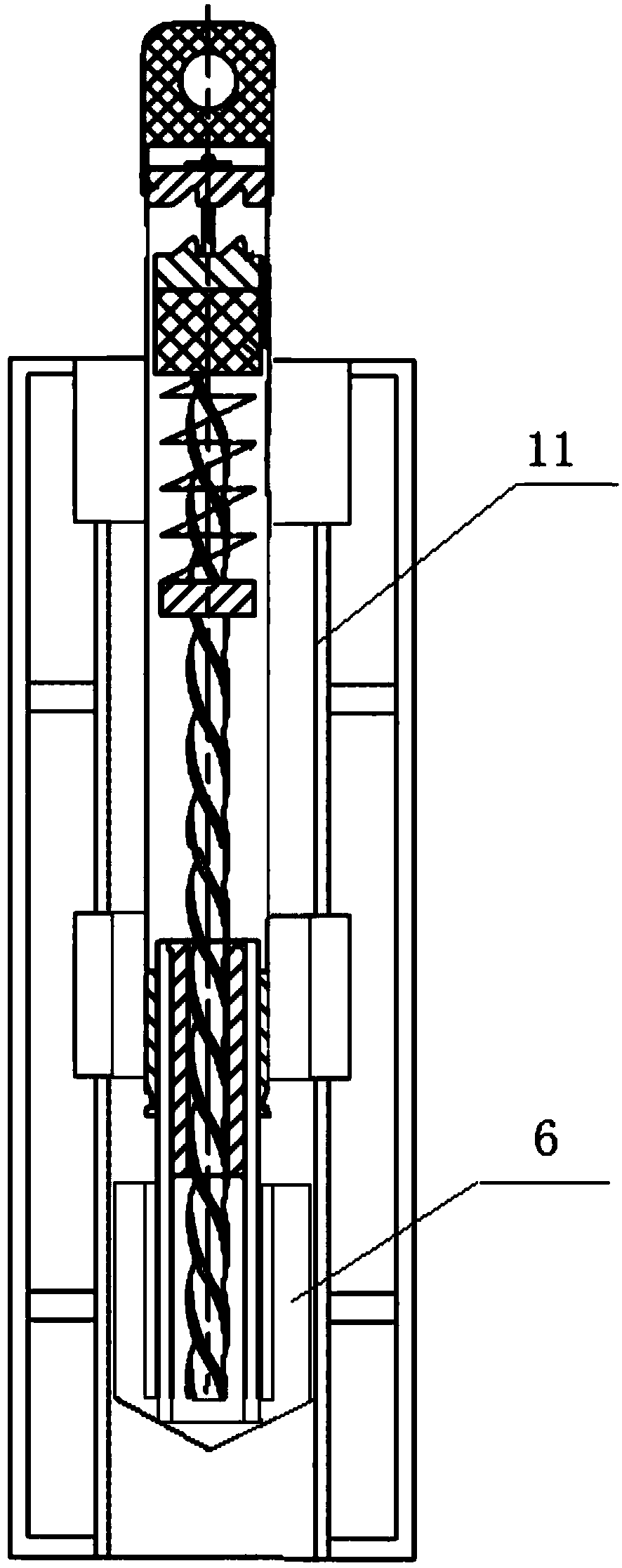

Embodiment 1

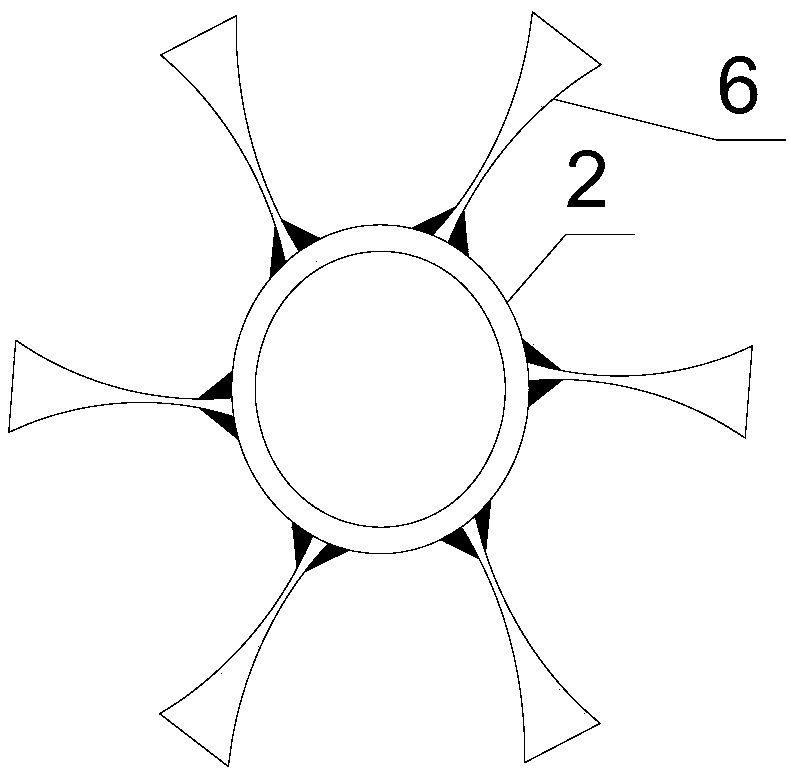

[0034] Such as image 3 As shown, the side ends of the blades 6 have blades. The blade 6 is in the form of a hyperboloid, forming a two-way blade at the outer end of the page. The blade 6 is a metal plate. The material of the blade 6 is stainless steel. It is vertically connected to the outer wall of the blade rotor. The included angle between two adjacent blades is the same.

Embodiment 2

[0036] Such as Figure 4 As shown, the page has blades on both the lower end face and the side end faces. Blade 6 is a shuttle-shaped surface, forming a blade at the end, which is conducive to scraping silt. The blade 6 is welded to the blade rotating rod, and the welding place is provided with reinforcing ribs. The design of the ribs can greatly improve the shear resistance of the blade 6 . The reinforcing rib can be a wedge-shaped metal block, which is welded between the blade 6 and the blade rotating rod 2, and directly fills the gap formed between the three. The purpose of this design is that it is easy to handle later. Although the gravity of the mud scraping device is increased, in actual operation, the increased gravity is more conducive to the rotation of the blades.

Embodiment 3

[0038] Such as Figure 5 Shown is a schematic structural view of the blade 6 . The pages have knives on both the lower end face and the side end faces. Blade 6 is a shuttle-shaped surface, forming a blade at the end, which is conducive to scraping silt. The blade 6 is welded to the blade rotating rod, and the welding place is provided with reinforcing ribs. The blade 6 can be designed to have a tip at the bottom, so that the plane shape of a single blade is trapezoidal or conical. For harder silt, it has a certain penetrating power and opens a passage for the blade 6 to enter the hard silt. Moreover, the side end surface of the blade 6 also has a blade portion, which makes the silt fall off rapidly under high-speed rotation after scraping the silt.

[0039] In the blade structures shown in Embodiment 1 and Embodiment 2, the bottom of the blade 6 can also be designed as a pointed portion, so as to further improve the working efficiency of scraping mud.

[0040] In order to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com