Steel structure color plate pavilion

A color plate and steel structure technology, which is applied to building components, building structures, special buildings, etc., can solve problems affecting the sealing and aesthetics of sloped roof ridges, and achieve the goals of reducing steel consumption, facilitating installation, and reducing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

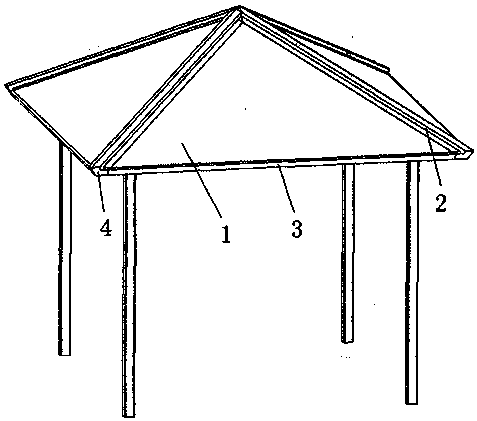

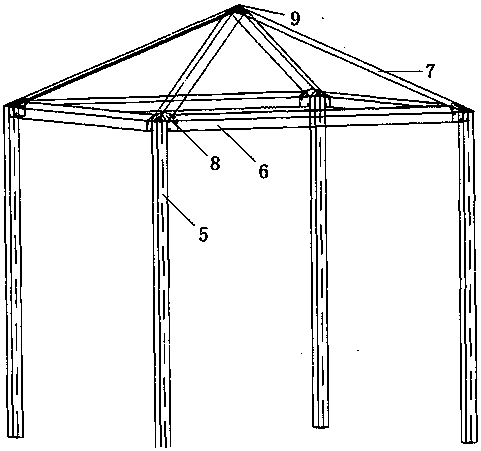

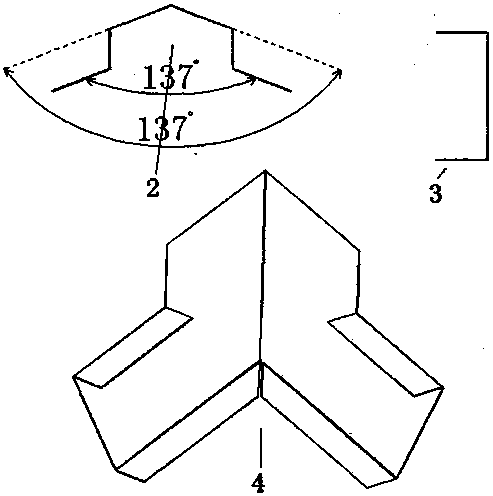

[0018] figure 1 and figure 2 It is an outline view of the appearance and a three-dimensional view of the steel skeleton of an embodiment of the present invention. The structure of the present invention adopts a steel structure, and its four-slope roof adopts double-sided flat color steel sandwich panels 1, and the four slanted roof ridges are covered with custom-made color steel ridge tiles 2, and the bottom of the four slope surfaces is wrapped with 3 packs of color boards. The four corners of the pavilion are sealed with custom-made color plate plugs 4.

[0019] The steel structure is mainly composed of columns 5, flat beams 6 and inclined beams 7, etc. Column 5 is 2.95m high and made of square steel pipes of 100mm x 100mm. Steel folded plate components 8 are welded on the tops of the four columns, and round holes are arranged on the steel component...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com