Carton box forming device

A technology of forming device and carton, which is applied in packaging, papermaking, transportation and packaging, etc., can solve the problems of high labor intensity of manual operation, rising production cost of a single carton, and high labor cost, and achieves ingenious device design, small footprint, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

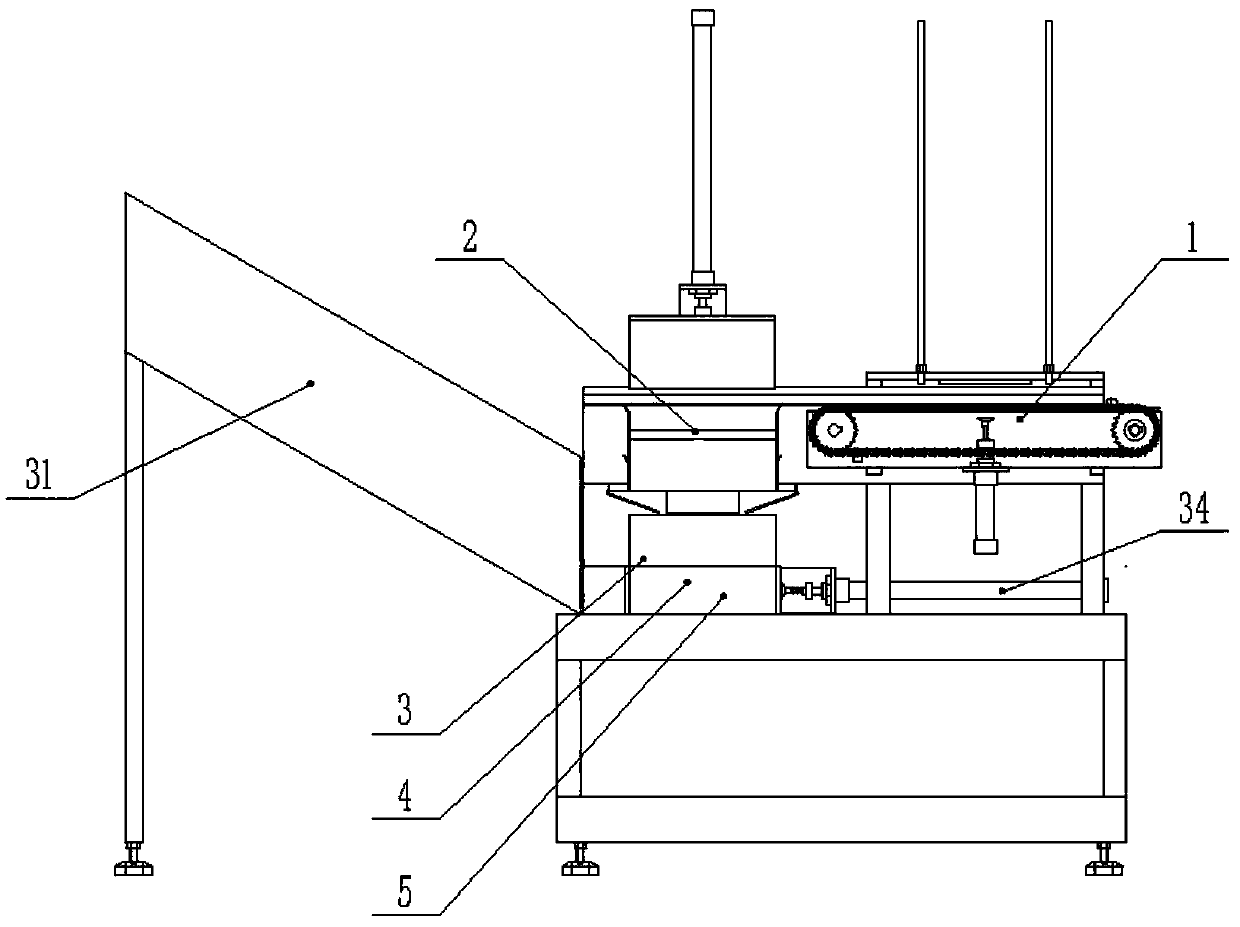

[0029] Such as figure 1 , figure 2 As shown, a carton forming device according to an embodiment of the present invention includes an inner box forming mechanism 2, an inner box collecting conveying mechanism 1 connected to the right side of the inner box forming mechanism 2, and an outer box located below the inner side of the inner box forming mechanism 2. The forming mechanism 3, the pushing mechanism 4 that pushes the outer box 7 from the outer box forming mechanism 3 to the inner box forming mechanism 2, and the case-out conveyor belt 5 positioned at the output end of the pushing mechanism 4.

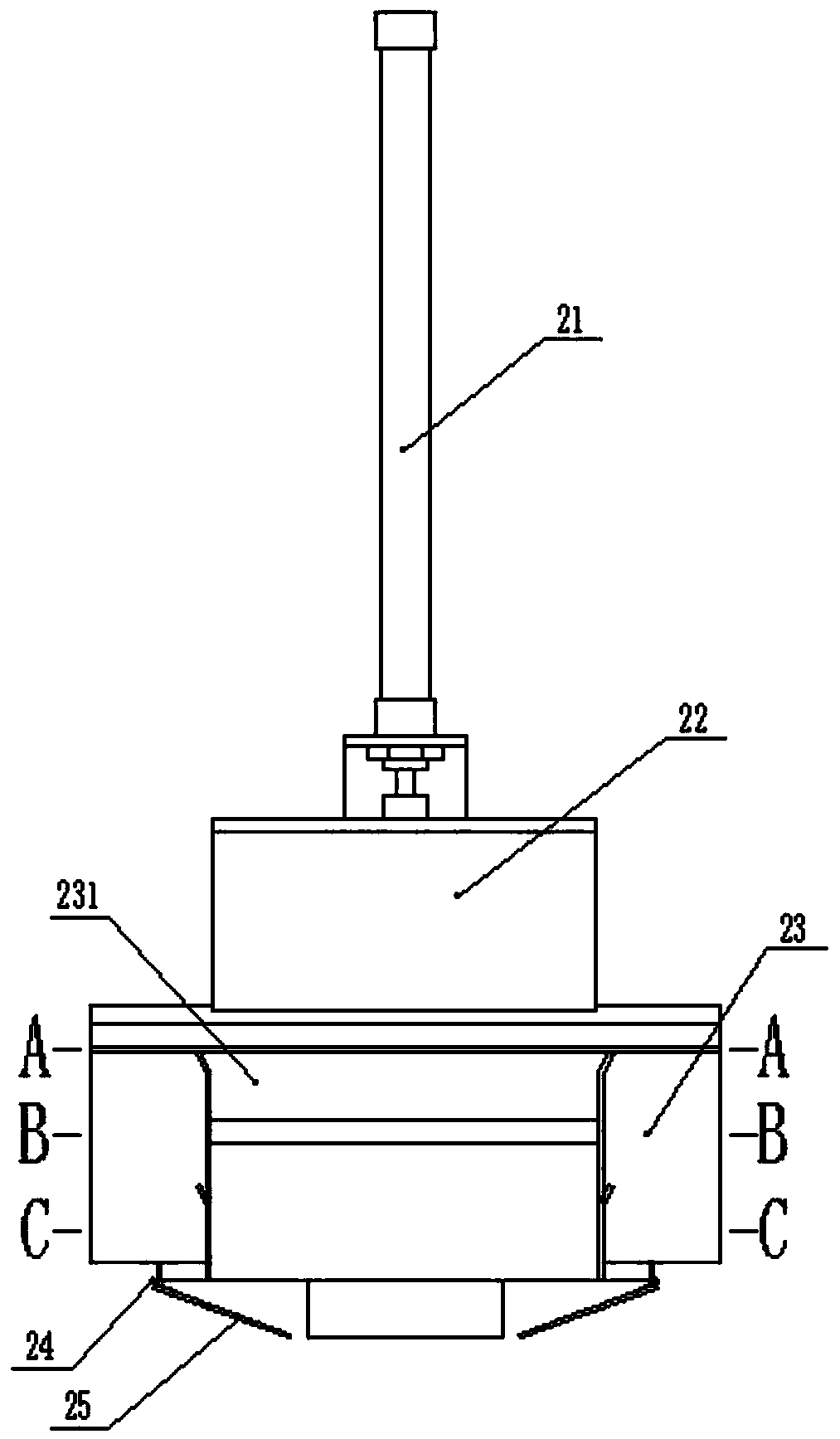

[0030] see image 3 , the inner box forming mechanism 2 includes a molding die 23, a cylinder 21 positioned at the top of the molding die 23, a molding block 22 is installed on the shaft end of the cylinder 21, the size of the molding block 22 is consistent with the bottom surface 61 of the inner box, and the inner processing molding cavity of the molding die 23 231, the cross-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com