Method of using a support adjustment structure for pipe butt welding

A technology for adjusting structures and pipelines, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as low alignment efficiency, difficulty, and slow down pipeline construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

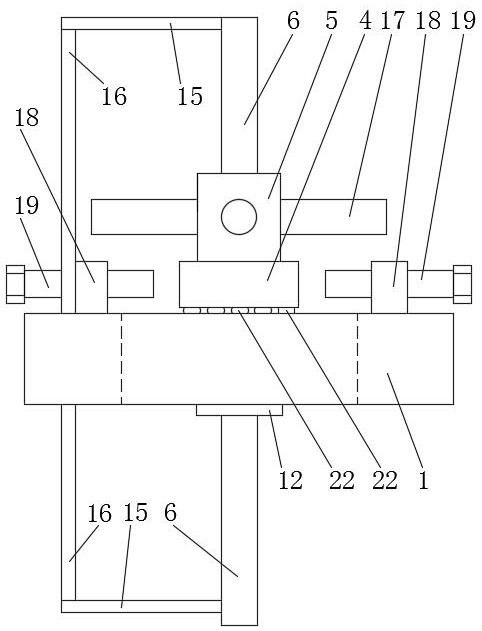

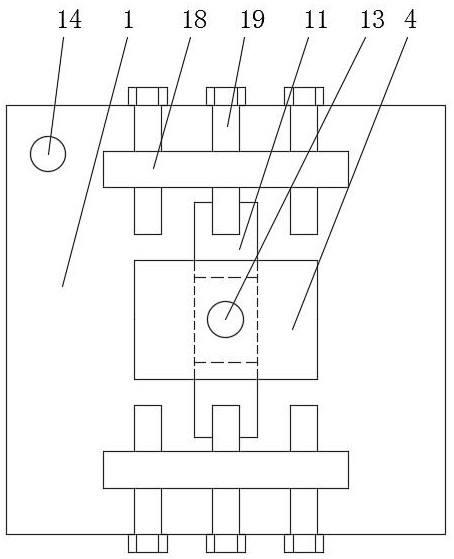

[0038] Such as Figures 1 to 6 As shown, the supporting adjustment structure for pipe butt welding,

[0039] It includes a support seat 1, at least three support rods 2, a pressure block 3, a lateral adjustment block 4, an adjustment sleeve 5 and an adjustment screw 6;

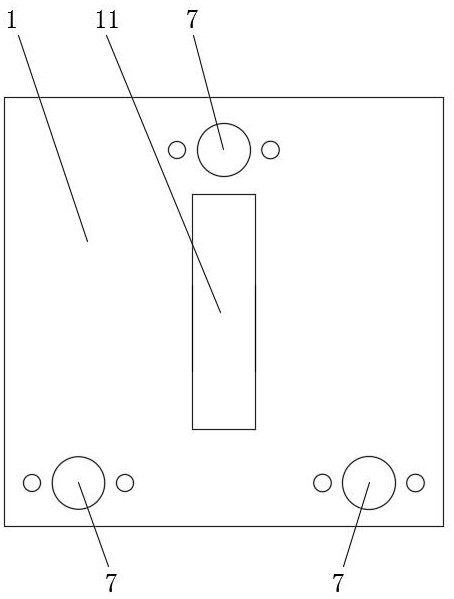

[0040] The bottom of the support seat 1 is provided with a semicircular groove 7, and the number of the semicircular groove 7 is the same as that of the support rod 2. The top of the support rod 2 has a mounting sphere 8, and the mounting sphere 8 is installed in the semicircular groove 7. The briquetting block 3 is provided with a through hole 9. The inner surface of the hole 9 is a spherical surface 10, the pressing block 3 is set on the lower half of the installation sphere 8 through the through hole 9, the pressing block 3 and the support seat 1 are fixedly connected by bolts, and the installation sphere 8 is pressed into the semicircular groove 7 , the installation sphere 8 can rotate in the semi-circula...

Embodiment 2

[0045] Such as figure 1 and 2 As shown, on the basis of Embodiment 1, the upper part of the support seat 1 has two adjustment seats 18, and the two adjustment seats 18 are respectively located at the left and right ends of the transverse rectangular guide hole 11, and the adjustment bolts 19 are threaded on the adjustment seats 18, and the adjustment bolts 19 is used to correspondingly push the left and right ends of the lateral adjustment block 4 to realize the lateral movement adjustment of the lateral adjustment block 4, and the adjustment bolt 19 can be adjusted by a socket wrench.

[0046] Specifically, three adjusting bolts 19 are arranged on each adjusting seat 18 , and one of the three adjusting bolts 19 at both ends is aligned with the middle of the left and right ends of the transverse adjusting block 4 .

Embodiment 3

[0048] Such as figure 1 , 7 As shown in and 8, on the basis of Embodiment 2, the top surface of the support seat 1 is provided with a long arc bottom groove 20, and the arc bottom groove 20 is parallel to the horizontal rectangular guide hole 11, and the horizontal rectangular guide hole 11 Both the front and rear ends have circular arc bottom grooves 20, specifically two circular arc bottom grooves 20 are arranged at the front and rear ends of the transverse rectangular guide hole 11, and the bottom surface of the horizontal adjustment block 4 is correspondingly provided with a strip-shaped circular arc top groove 21. Some balls 22 are installed in the bottom groove 20, and the balls 22 are steel balls 22. The arc top groove 21 covers and is arranged on the top of each ball 22, and each ball 22 is covered with a skeleton (not shown in the figure), and the skeleton holds each ball. 22 are separated, and the lateral adjustment block 4 is adjusted laterally on the upper surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com