A low-temperature carbon-based combined desulfurization and denitrification flue gas device and its use method

A desulfurization and denitrification, carbon-based technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of inconvenient dust push, inconvenient cleaning dust, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

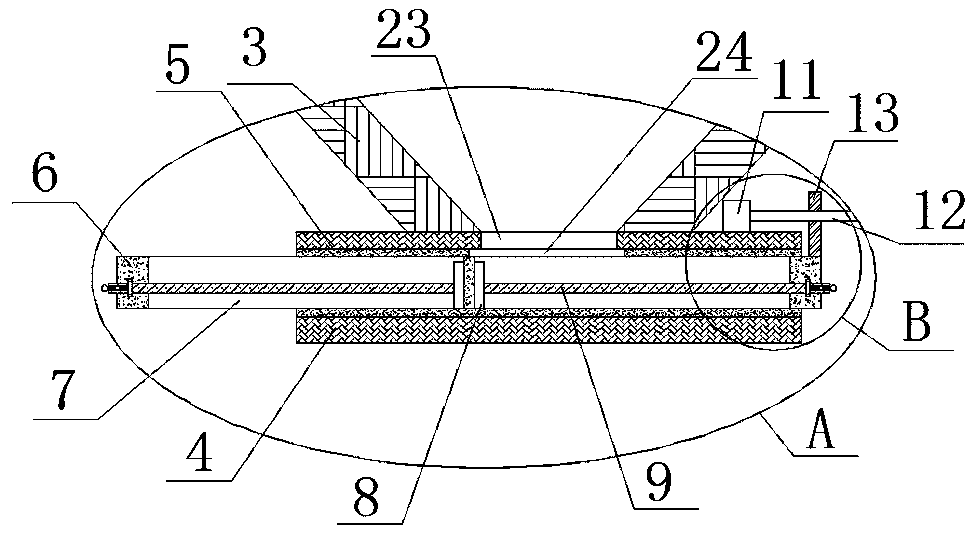

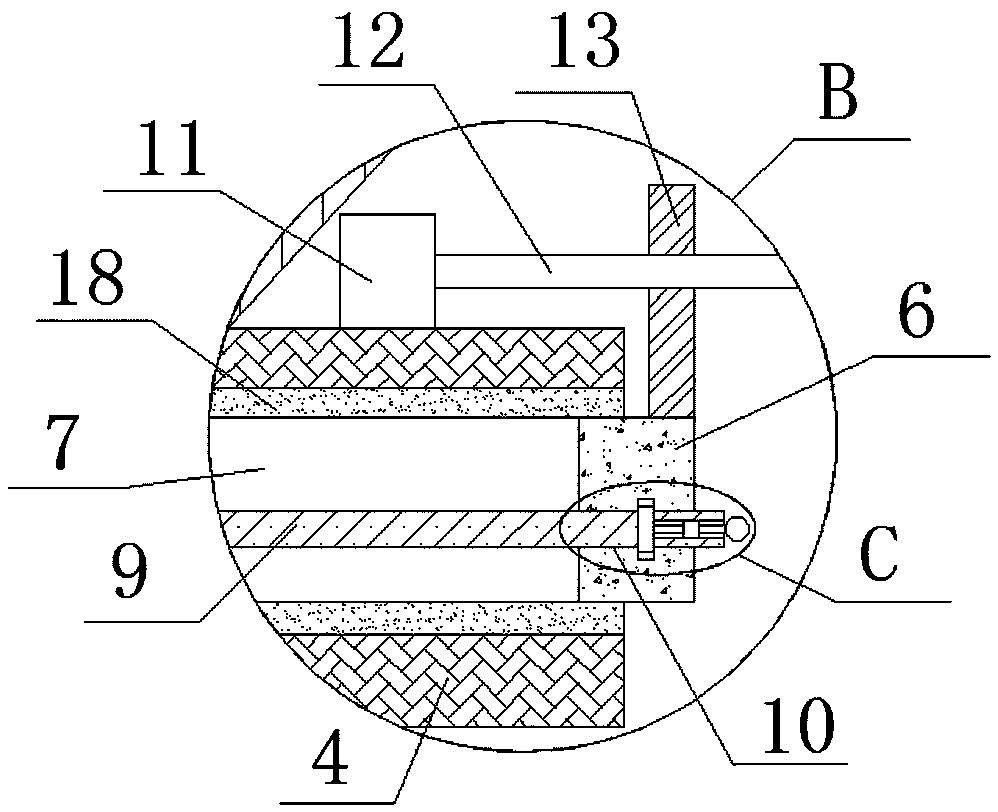

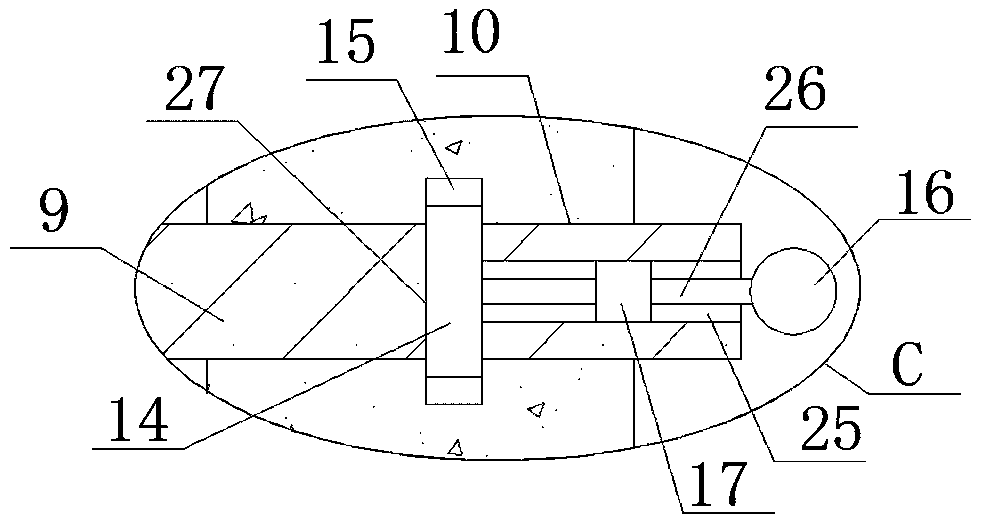

[0031] refer to Figure 1-5In this embodiment, a low-temperature carbon-based combined desulfurization and denitrification flue gas device is proposed, including a fluidized bed body 1, a chamber 2 is arranged on the fluidized bed body 1, the bottom of the chamber 2 is set as an opening, and the chamber 2 A first catalyst plate 20 and a second catalyst plate 21 are fixedly installed on the side wall of the fluidized bed body 1. The bottom of the fluidized bed body 1 is fixedly connected with a conical ash hopper 3, and the bottom of the conical ash hopper 3 is fixedly installed with a baffle plate 4. One side of the plate 4 is provided with a mounting hole 5, and a bearing plate 6 is movably installed in the mounting hole 5, and a storage hole 7 is opened on both sides of the top of the bearing plate 6, and the inner wall of the side where the two storage holes 7 are close to each other is movable. Sliding plates 8 are installed, and the sides of the two sliding plates 8 that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com