Simulation experiment device for gas extraction spontaneous combustion in coal bed gob region

A simulation experiment device, gas extraction technology, applied in gas emission, safety devices, mining equipment, etc., can solve the problems of inability to form spontaneous combustion, large differences in the number of coal blocks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

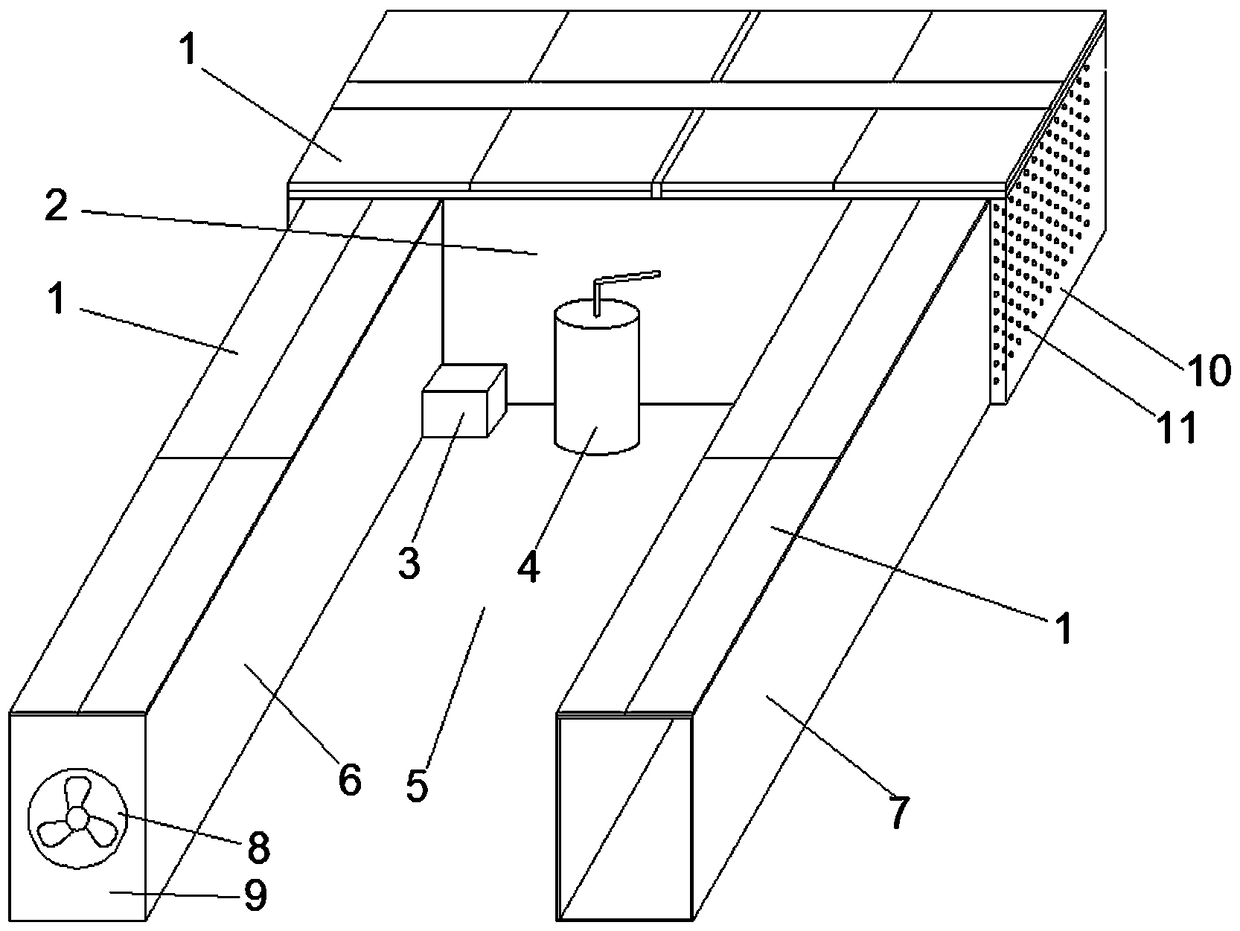

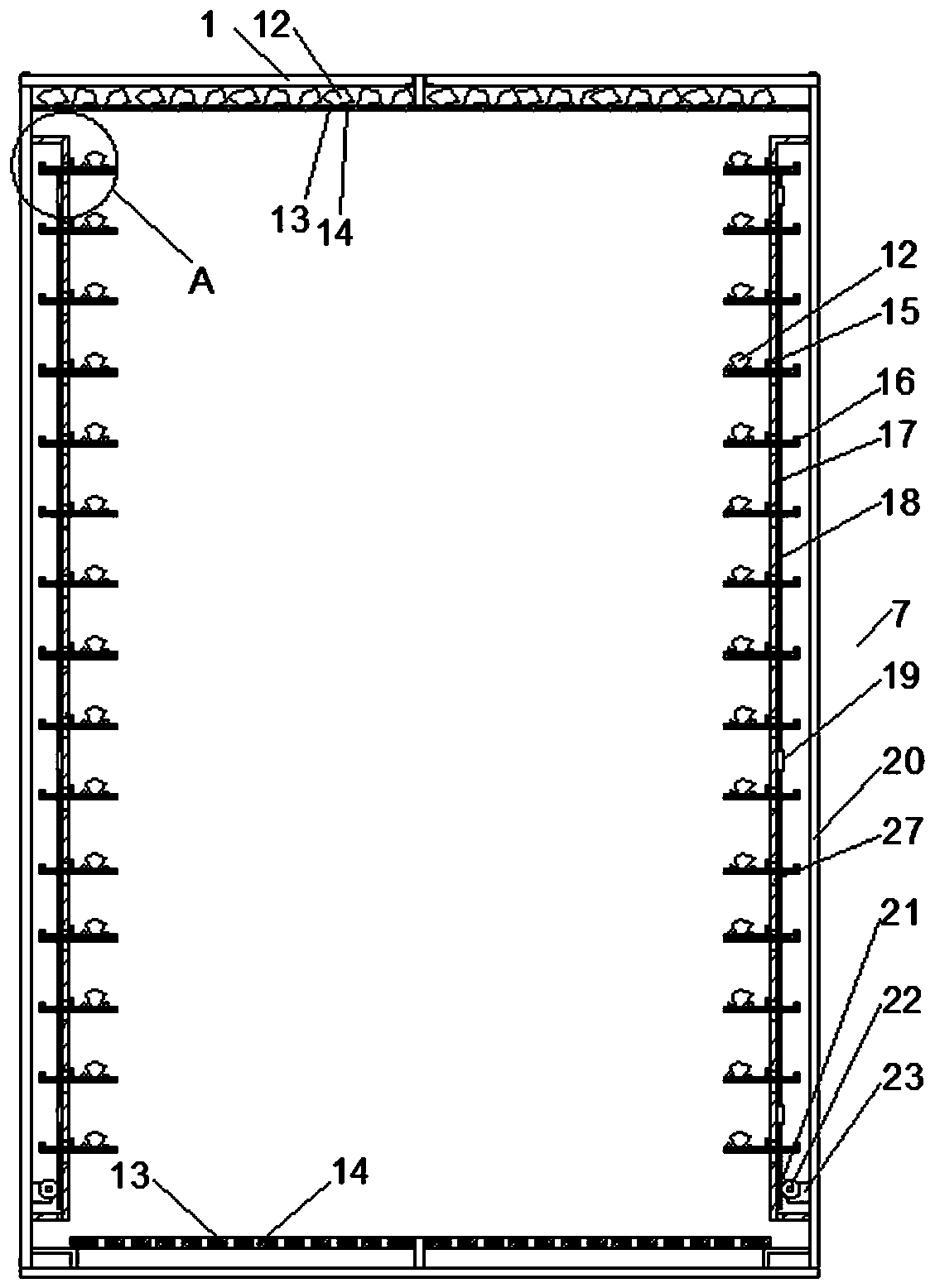

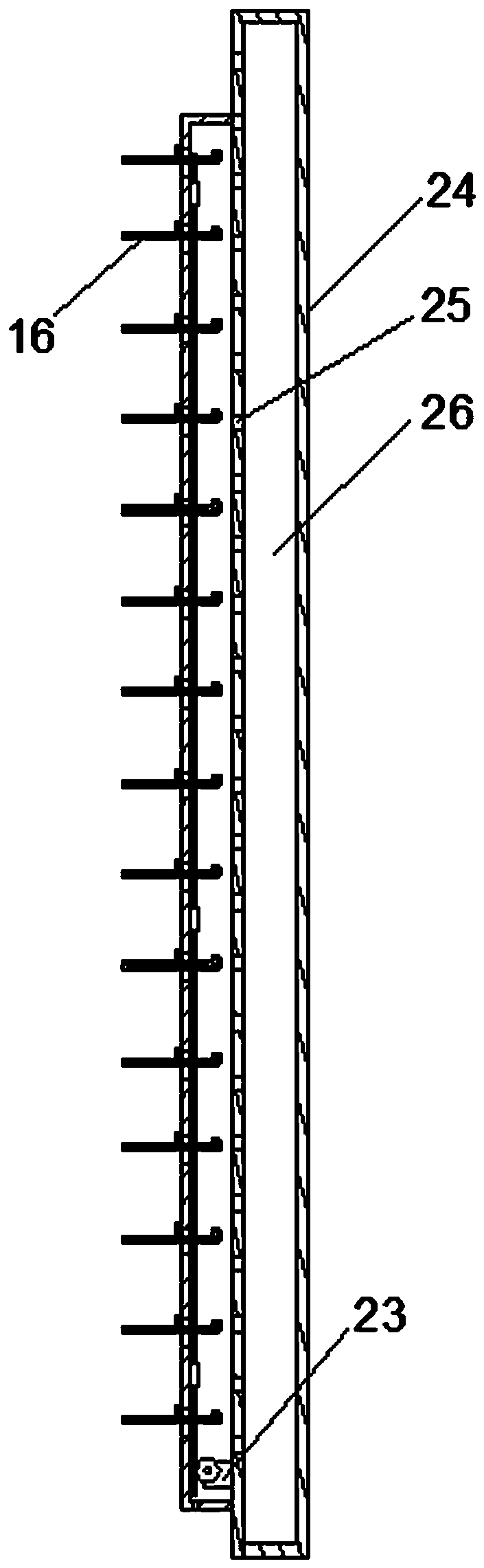

[0023] An example of an example of a spontaneous combustion simulation test device for gas drainage in a coal seam goaf Figures 1~8 Shown: it includes a U-shaped channel composed of two side wall channels and a bottom channel connected between the two side wall channels, wherein the inner hole of one side wall channel forms an air inlet tunnel 7, and the inner hole of the other side wall channel The hole forms the return air roadway 6, the inner hole of the bottom channel forms the goaf 2, the roadway mouth sealing plate 9 is provided at the roadway mouth of the return air roadway, and the extraction fan 8 is provided on the roadway mouth sealing plate. An empty placement area 5 is formed between the two side wall passages. The placement area is provided with a gas tank 4 for supplying gas to the goaf, and a gas drainage pump 3 is also placed in the placement area. Empty areas are connected. The top and bottom channel walls of the U-shaped channel are provided with coal stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com