Control device of efficient binding machine

A control device and binding machine technology, applied in binding and other directions, can solve problems such as insufficient aesthetics and poor punching quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

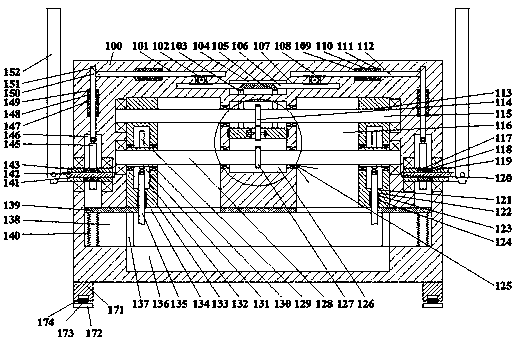

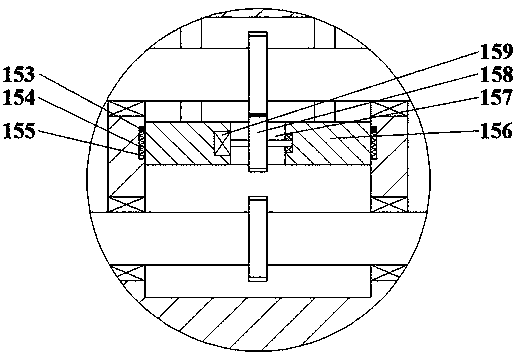

[0016] Such as Figure 1-Figure 2 As shown, the control device of the high-efficiency binding machine of the present invention includes a body 100, a first cavity 138 disposed in the body 100, and a second cavity 126 disposed in the body 100, the The top wall of the first cavity 138 is left and right symmetrically provided with the third cavity 116 with the opening downward. The first sliding block 139 can be slid up and down in the first cavity 138 . A through hole 134 corresponding to the third cavity 116 is symmetrically arranged left and right, and a second sliding block 133 is slidably arranged in the third cavity 116, and a left and right through hole is arranged in the second sliding block 133. The first threaded hole 113, the first threaded hole 113 is internally threaded and connected with the first threaded rod 115 passing through the second cavity 126, and the left and right sides of the first threaded rod 115 are rotated and arranged on the third In the end wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com