Thin-walled equipment lifting lug reinforcing method

A lifting lug and equipment technology, applied in the field of lifting lug reinforcement for thin-walled equipment, can solve the problems of lifting lug design requirements for hoisting, unsatisfactory tube wall thickness, and inability to replace the tube section with a thicker tube section, etc., and meet the manufacturing process requirements Low, meet the effect of hoisting requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

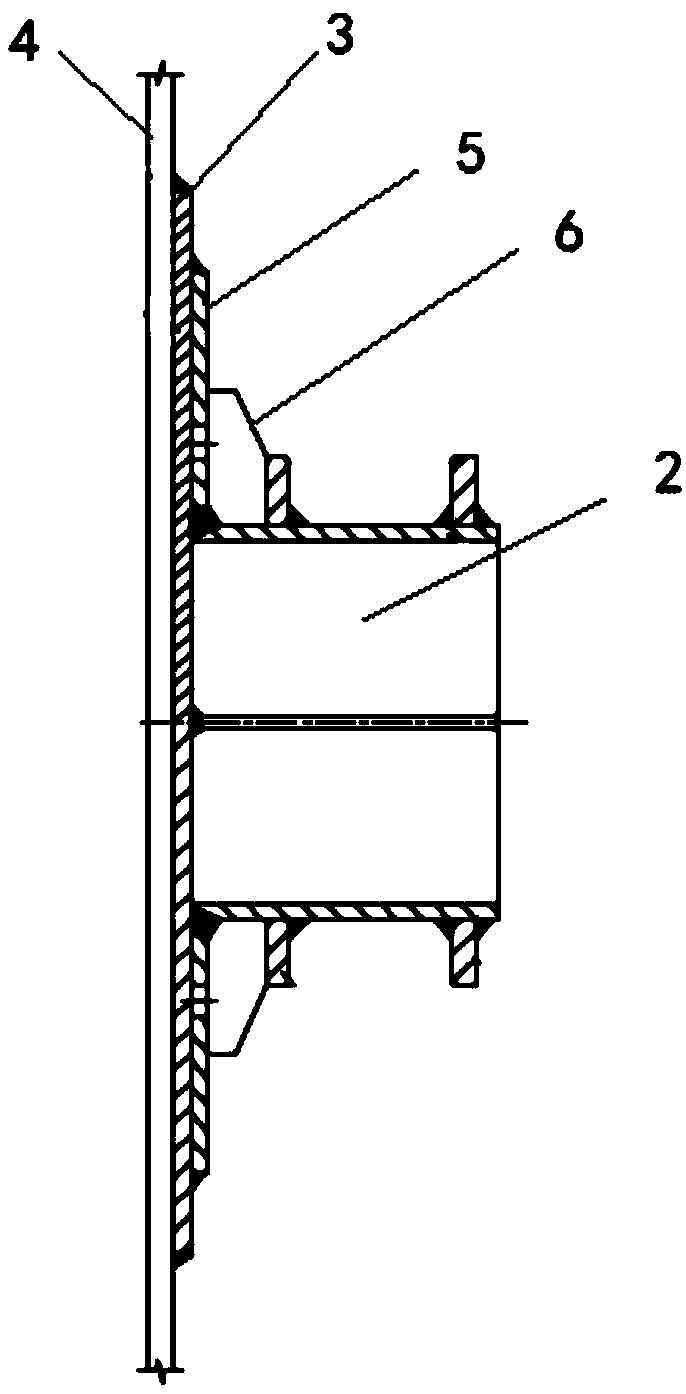

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] A method for strengthening lifting lugs of thin-walled equipment, see figure 2 , including the following steps:

[0022] 1. By referring to the design specifications of the lifting lugs, judge whether the diameter of the main body of the equipment to be hoisted 1 and the thickness of the cylinder wall 4 exceed the design requirements of the lifting lugs. It is also possible to check whether the wall thickness of the main body of the equipment 1 to be hoisted meets the hoisting requirements by checking the local stress. If it is not satisfied, it can be judged as thin-walled equipment.

[0023] 2. Add a reinforcing ring cylinder 3 to the cylinder wall 4 of the equipment to be hoisted 1;

[0024] For thin-walled equipment, a reinforcing ring cylinder 3 is added around the pre-designed position of the cylinder wall 4 where the lifting lug will be installed to s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com