Method for manufacturing sleepers for use in rail superstructures

A technology for sleepers and rails, applied in the field of sleepers formed by plastic-sand-mixture, can solve the problems of lack of elasticity, non-elasticity, heavy weight, etc., and achieve the effect of low price and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

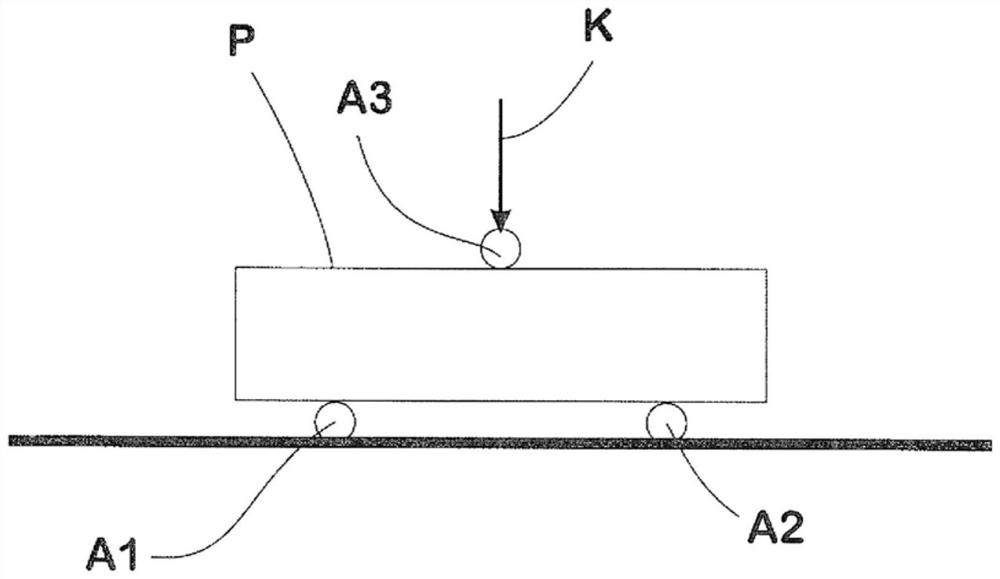

Image

Examples

Embodiment Construction

[0037] The present invention is further described below according to the examples.

[0038] Quartz sand is provided for the production of cuboidally elongated sleepers for the superstructure of gravel track beds in the conventional manner. The bulk density of the sand is about 1.9g / cm 3 , the Mohs hardness is 7 and the average particle size of the sand particles is 0.1-<0.5mm.

[0039] Likewise, plastic granules are provided which consist of a mixture of polypropylene plastic granules (PP granules). The melt flow index of PP plastic particles measured under the conditions of 230°C and 2.16kg load is greater than 20.

[0040] Before being mixed with the plastic granules, the sand is heated to 220° C. by means of a heated wick immersed in it and heated by means of thermal oil. In contrast, the temperature of plastic pellets is equal to room temperature.

[0041] The hot sand is then mixed with plastic pellets. The sand and plastic granules are dosed in such a way that the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com