Resealable can lid

A technology for can lids and beverage cans, which is applied in the field of reclosable can lids, and can solve the problems of being pressed into the interior of the can and contacting with liquid, unable to be reclosed, and hygiene problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

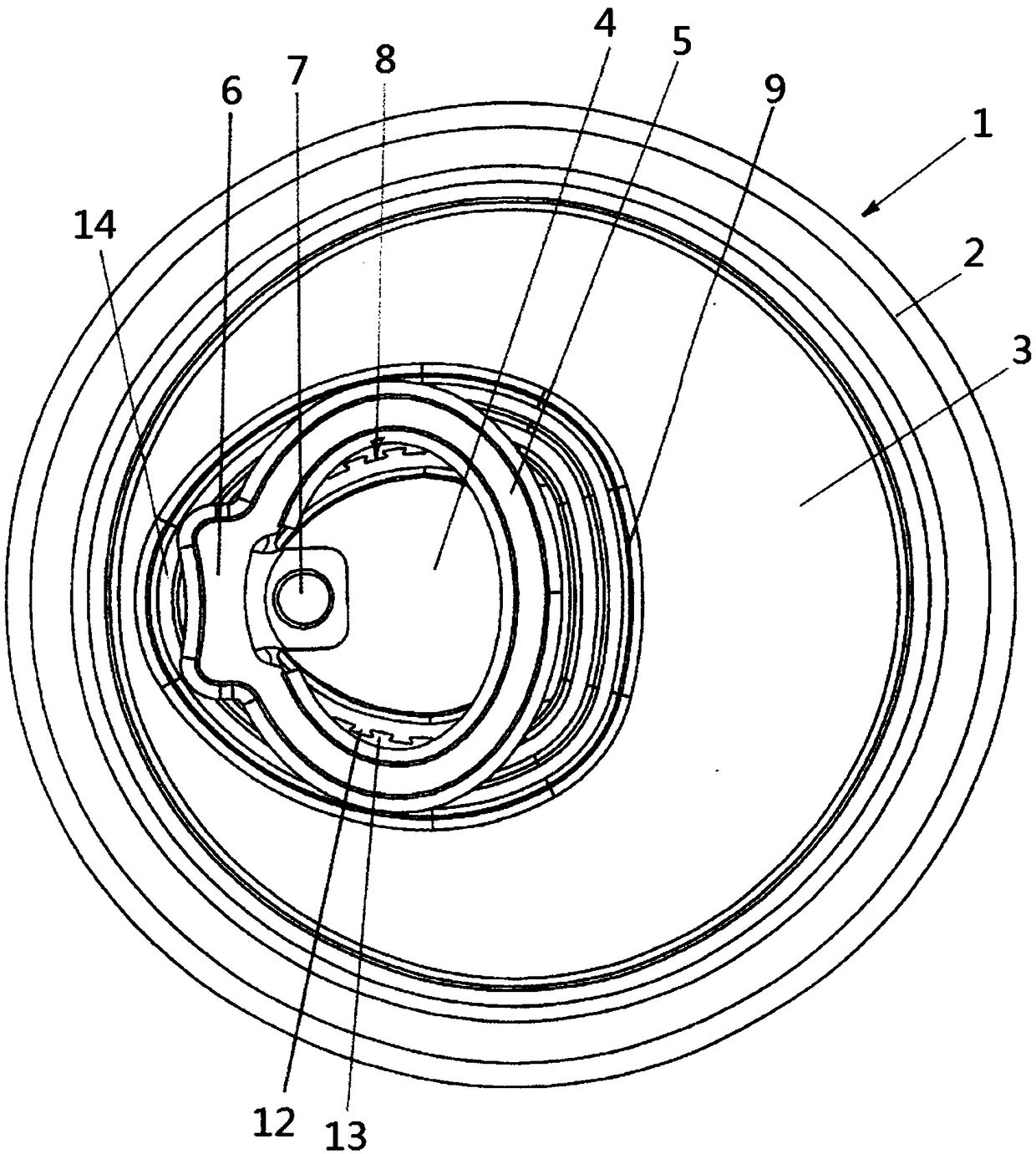

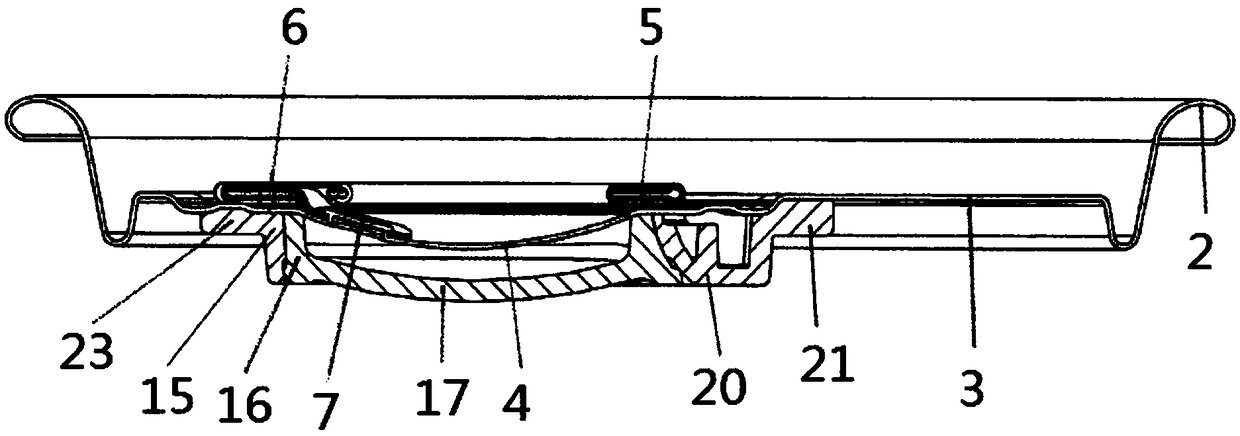

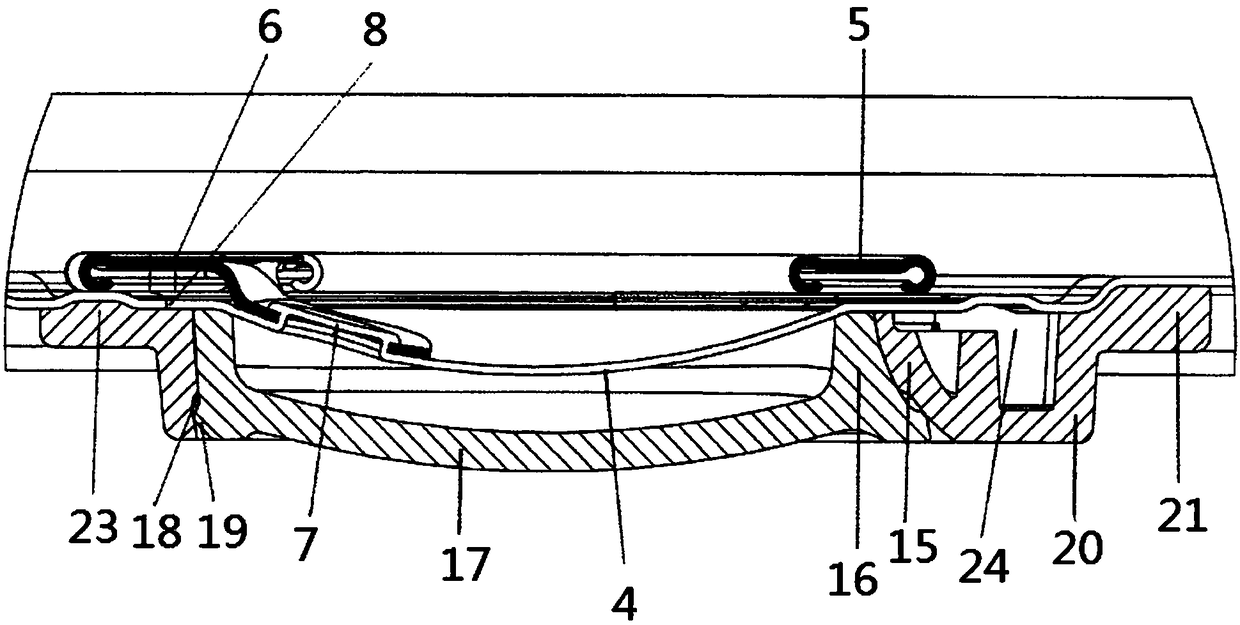

[0036] figure 1 An embodiment of a can end according to the invention is shown in a schematic plan view. Said can end is provided with a bead 2 in the conventional manner in its peripheral area, wherein the area arranged inside the bead 2 is formed by a cover surface 3 having an opening area formed opposite to the Center offset tongue 4. Such a metal can end comprising aluminum material is arranged around the opening area 4 , wherein at least one reinforcement area 14 is formed by deformation of the material.

[0037] The double-arm bars 5 , 6 are connected (in particular riveted or welded) to the tongue 4 of the can lid 1 delimiting the area of the opening so that a fixed connection point 7 is formed. This connection point 7 is arranged in the edge region of the tongue 4 or opening region, ie opposite the tongue base, which is connected to the lid surface 3 and forms a pivot bearing region 9 during opening. The double-arm lever comprises a shorter area and a longer area,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com