A simple forming method of armature coil with different slots in dc traction motor

An armature coil, DC traction technology, applied in the manufacture of motor generators, electric components, electrical components, etc., can solve the problem that the upper side is difficult to accurately correspond to two adjacent slots, the lower side of the armature coil is poorly compliant, and the lower side is difficult to fit. The overall section thickness and other problems can achieve the effect of easy inlay, good integration and high degree of conformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

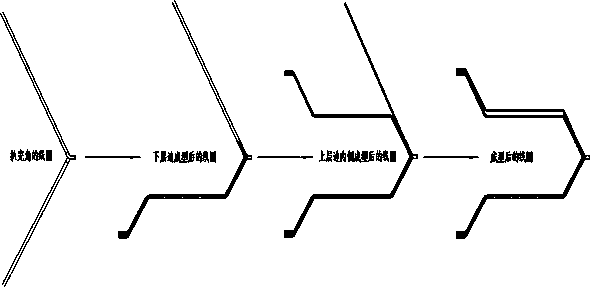

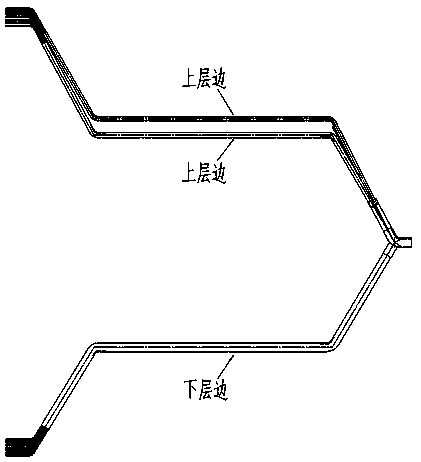

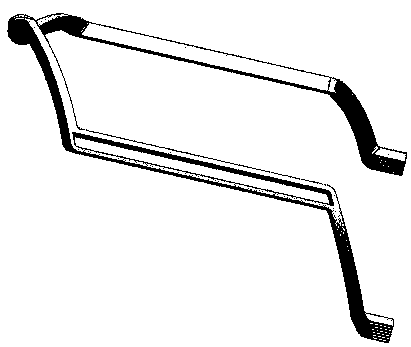

[0019] The present invention proposes a simple forming method for different-slot armature coils of DC traction motors, such as figure 1 shown, including the following steps:

[0020] S1. Armature coil pretreatment: stick two sets of armature coils together, and perform cornering treatment on the middle part of the armature coil to form a nose, and then clip the nose of the armature coil held on a knockout mould;

[0021] S2. Treatment of the lower side of the armature coil: protect the armature coil with a non-metallic pad, and use a metal hammer to strike the non-metallic pad to shape the armature coil, and connect the lower side of the armature coil with the The knocking mold is fully fitted, and then the lower edge after th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com