Glass drier

A dryer and glass technology, which is applied in the field of drying equipment and glass plate water removal, can solve the problems of affecting work efficiency, low drying efficiency, glass plate breakage, etc., and achieve the effect of improving the use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

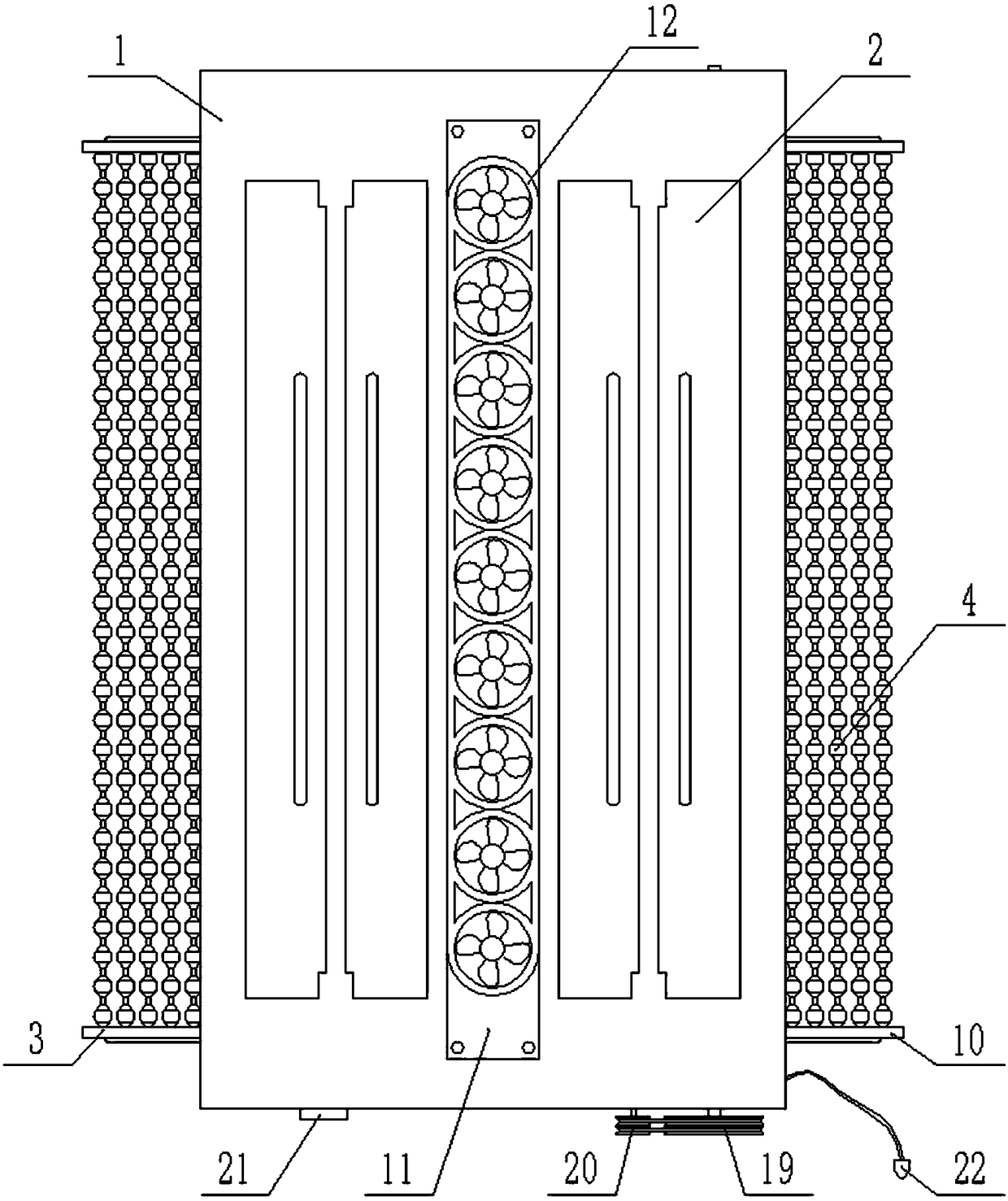

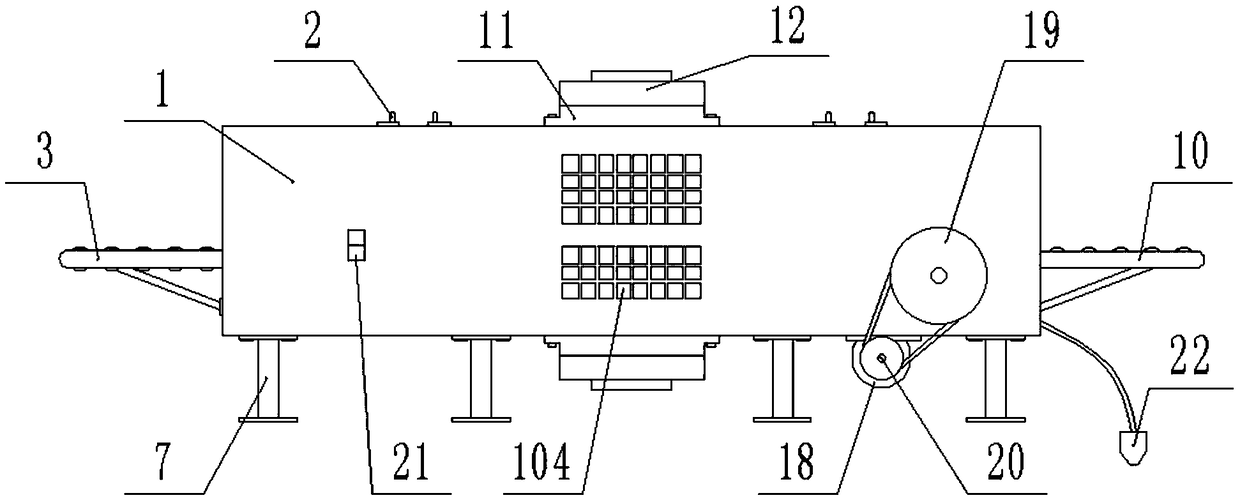

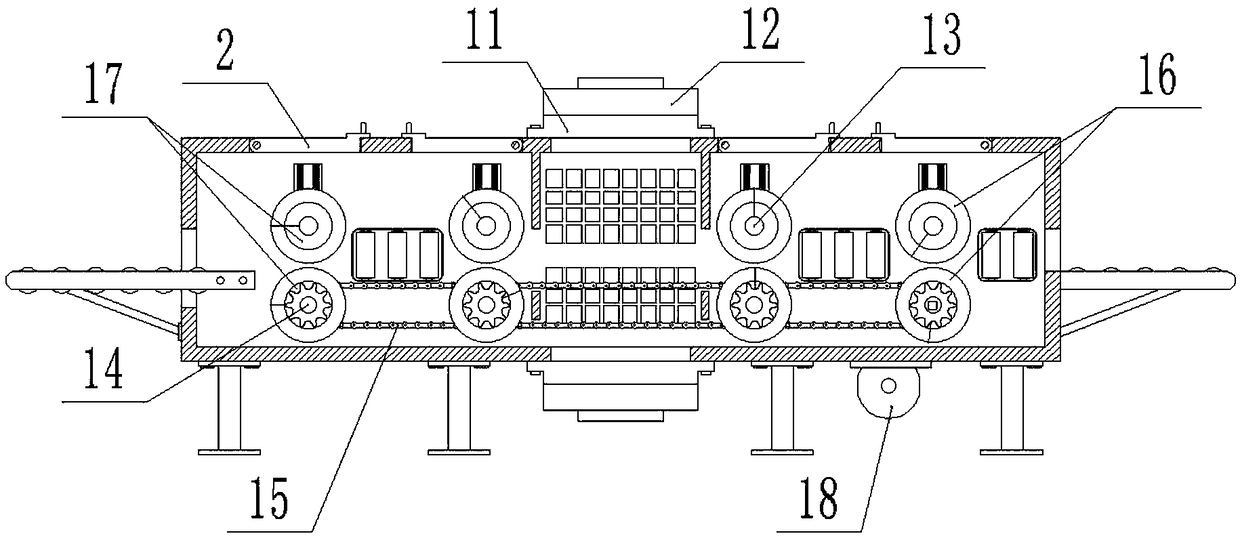

[0036] as attached figure 1 To attach Figure 9 Shown:

[0037]The present invention provides a glass dryer, including a main body 1, a feed hole 101, a replacement hole 102, a chute 103, an exhaust hole 104, an air inlet 105, a discharge hole 106, a top cover plate 2, a feed plate 3, Ball 4, pressing spring 5, slider 6, support column 7, locking block 8, rubber roller 9, discharge plate 10, electric furnace wire heating plate 11, fan 12, driven shaft 13, driving shaft 14, chain 15 , water-absorbing sponge 16, rubber ring 17, rubber fixing block 1701, rubber fixing groove 1702, motor 18, driven wheel 19, driving wheel 20, power switch 21 and power plug 22, the left side of the main body 1 is provided with a feeding hole 101, and four replacement holes 102 are provided on the top end surface of the main body 1, and the top cover plate 2 is rotatably connected in the replacement hole 102, and four sliding grooves 103 are respectively provided on the front and rear sides of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com