a tire mold

A tire mold and mold shell technology, applied in the field of tire manufacturing, can solve the problems of easy delamination, damage to tire wear resistance, and inability to use, so as to avoid extrusion or other damage, prolong service life, and facilitate wiring and dismantling line effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

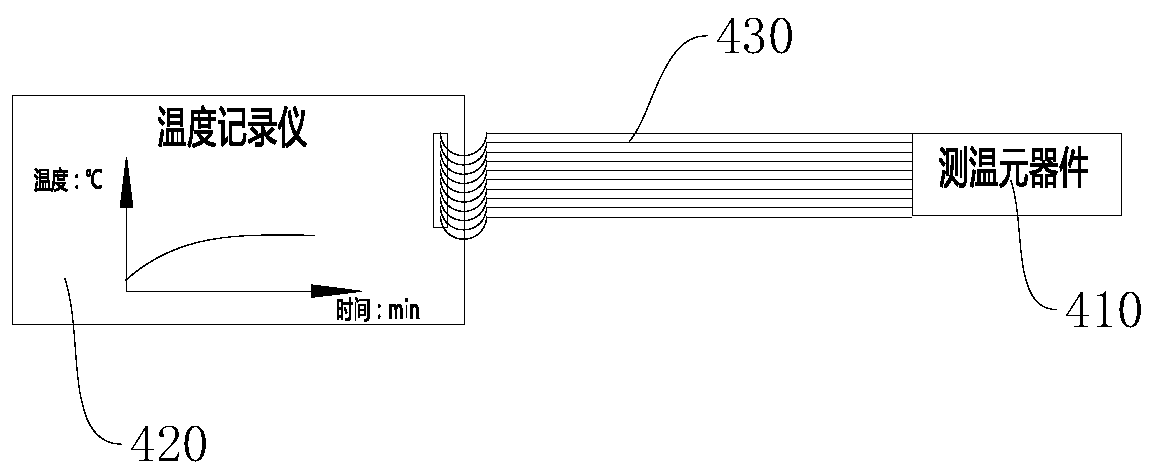

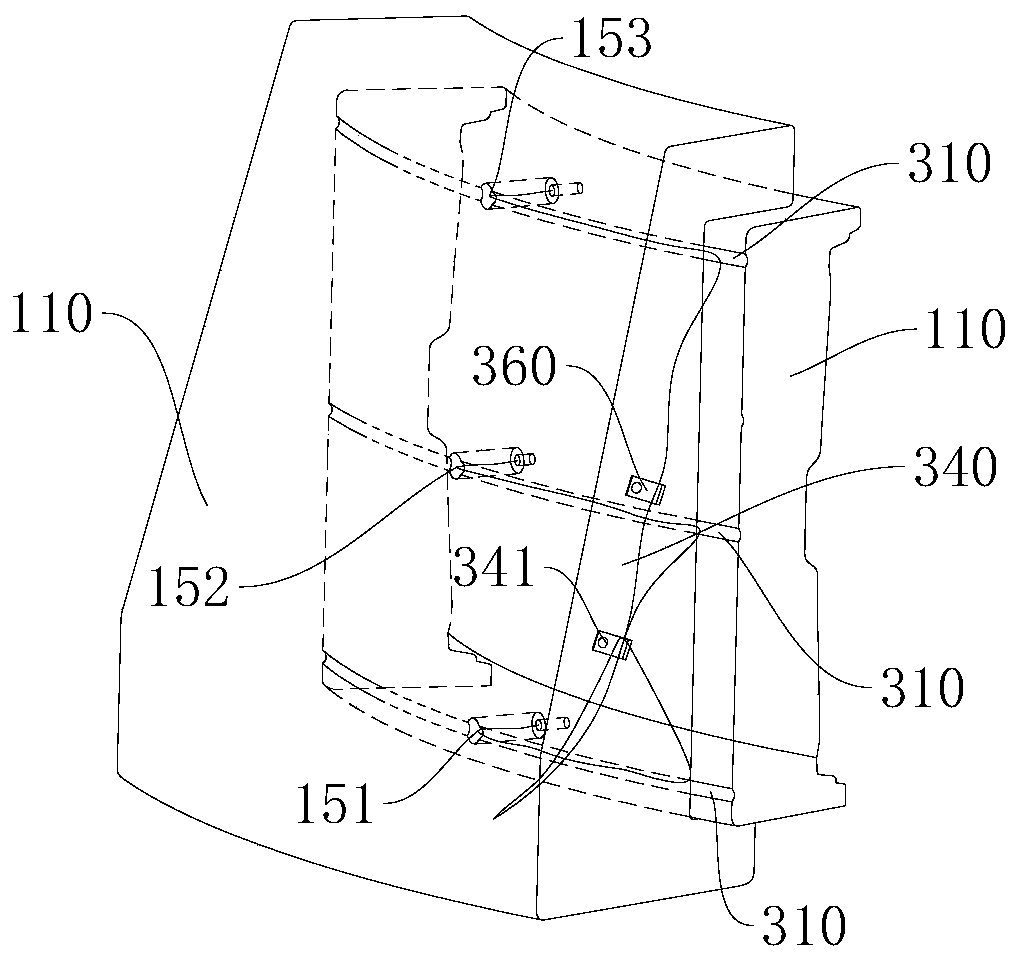

[0045] figure 1 A schematic diagram of the overall structure of the tire mold 010 provided in this embodiment. Please refer to figure 1, the present embodiment provides a tire mold 010 , which includes a mold shell assembly 200 and a cavity assembly 100 disposed in the mold shell assembly 200 . The cavity assembly 100 includes an upper side plate 130 and a plurality of pattern blocks 110 arranged along the circumference of the upper side plate 130, at least one of the pattern blocks 110 or the upper side plate 130 is opened with a temperature measuring hole 150, and the temperature measuring hole 150 is set There is a temperature measuring element 410 . The tire mold 010 is equipped with a wire-passing groove connected to the temperature measuring hole 150, and the temperature-measuring wire 430 of the temperature-measuring element 410 passes through the wire-passing groove to be led out of the cavity assembly 100, realizing the tire mold 010 preheating and tire vulcanizatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com