Grinding wheels and grinding device

A grinding device and grinding wheel technology, applied in grain processing and other directions, can solve problems such as low grinding efficiency, achieve good grinding effect, improve grinding efficiency, and solve the effect of low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

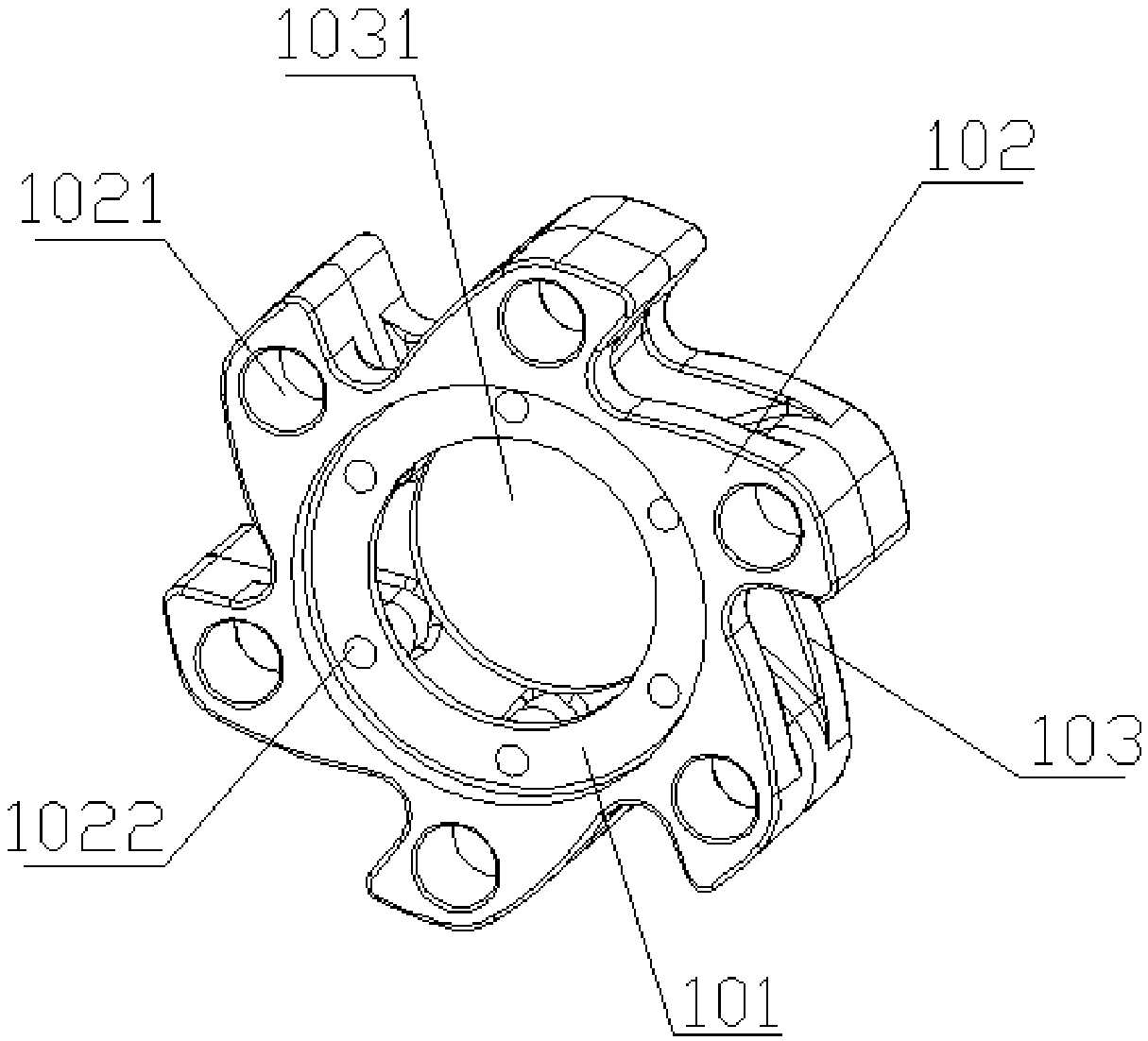

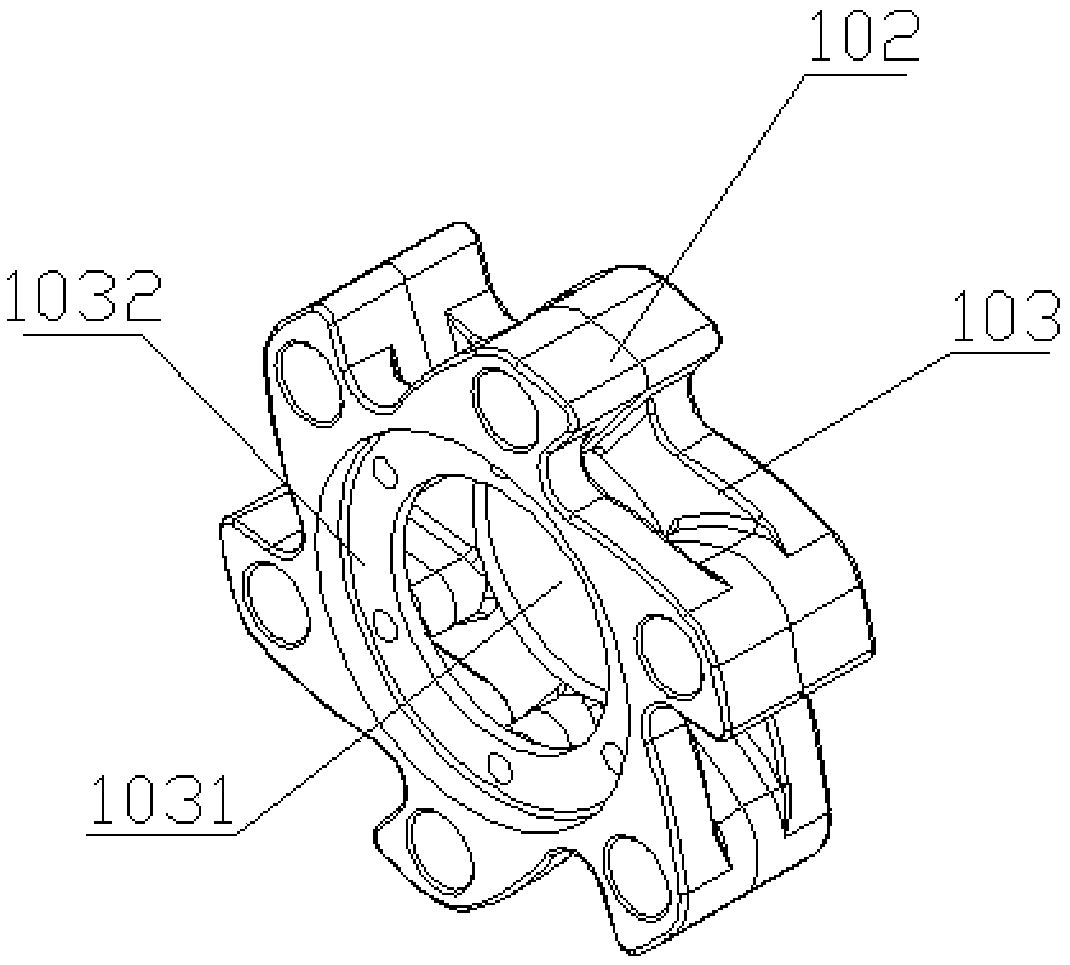

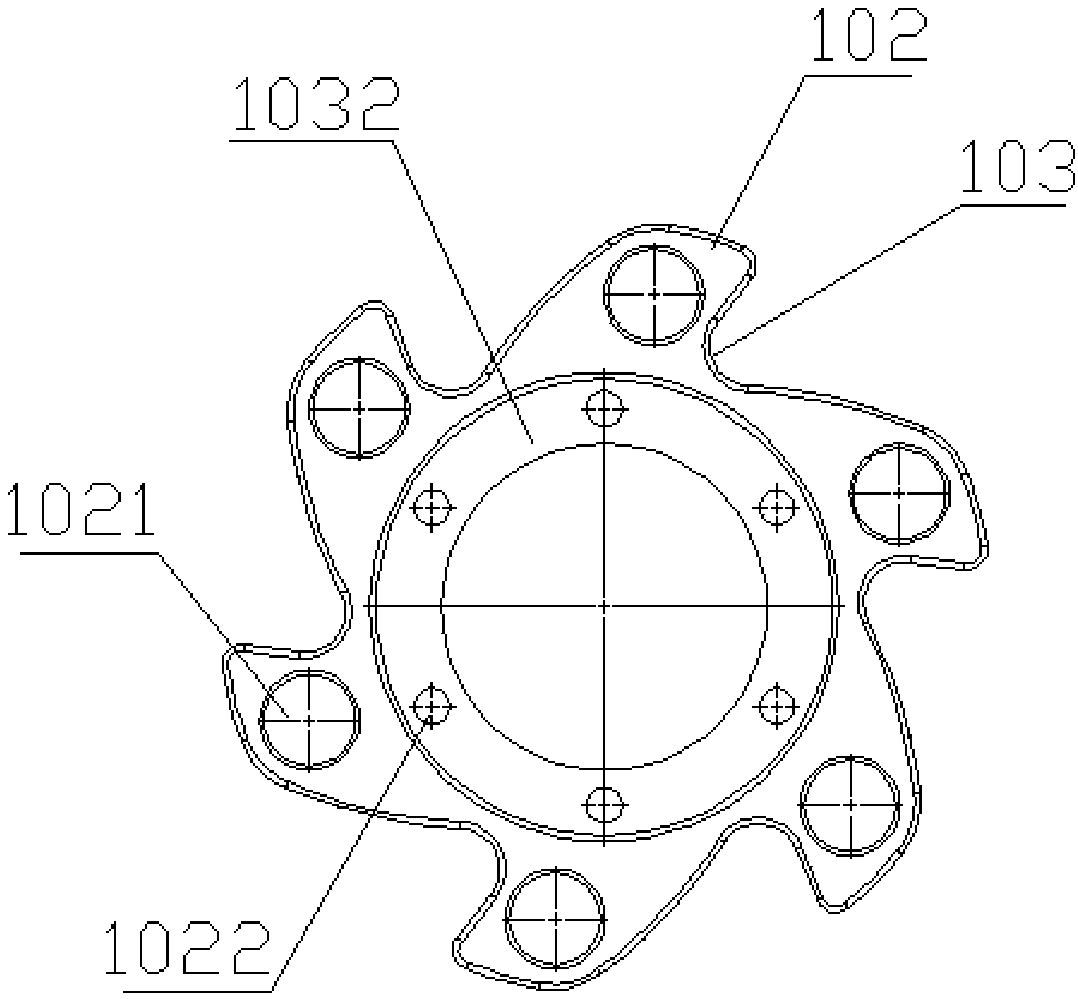

[0037] Such as Figure 1-3 As shown, the grinding wheel provided in this embodiment includes: a wheel body 101, a plurality of grinding teeth 102 are arranged on the wheel body 101, and tooth grooves 103 are arranged between two adjacent grinding teeth 102, and the teeth The slot 103 is arc-shaped; the grinding teeth 102 are arranged obliquely, and the inclination direction of the plurality of grinding teeth 102 is consistent with the rotation direction of the wheel body 101 . When working, the material is more fully radially ground under the action of centrifugal force, the exchange of materials at different positions is more frequent, and the collision between the material and the grinding wheel is more frequent, the solid particles in the material are dispersed finer, the grinding effect is better, and it is also conducive to heat dissipation .

[0038] It should be noted that there are multiple grinding wheels, usually six, to form a partial hexagonal structure, so that t...

Embodiment 2

[0049] Such as Figure 4 As shown, the grinding device provided in this embodiment includes: a housing 200 and a rotating shaft 300, the housing 200 is provided with a filtering structure 203 and the above-mentioned grinding wheel 100; the grinding wheel 100 is arranged on the rotating shaft 300 , the grinding wheel 100 rotates through the rotating shaft 300 .

[0050] It should be noted that the rotating shaft 300 is driven to rotate by a driving mechanism, wherein the driving mechanism may be a motor.

[0051] Specifically, the grinding wheel 100 is connected to the rotating shaft 300 through the connecting body 202, the end of the connecting body 202 is provided with a concave structure, and part of the filtering structure 203 is inserted into the concave structure; therefore, the setting of the concave structure , can further reduce the length of the housing 200 and reduce the occupied space of the housing 200 .

[0052] Further, the housing 200 is provided with a materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com