Fully automatic battery forming fixture machine

A technology of battery formation and fixture machine, which is applied in secondary batteries, electrochemical generators, non-aqueous electrolyte batteries, etc., can solve the problems of time waste, material cost waste, production waste, etc., to improve production efficiency and reduce fixture replacement. the effect of the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

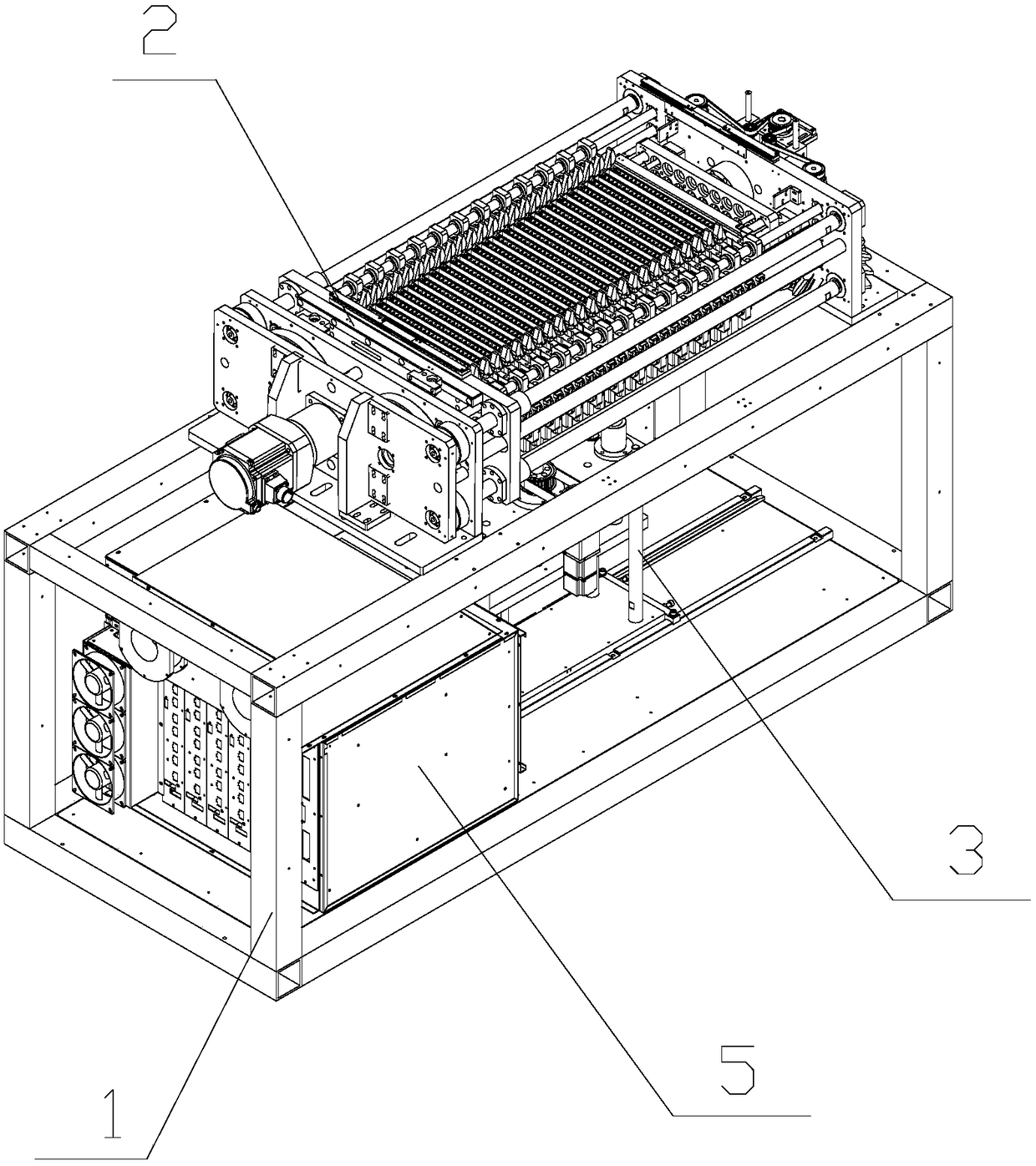

[0043] Embodiment 1 The fully automatic battery formation jig machine described in the present invention includes:

[0044] Rack 1;

[0045] The automatic clamping mechanism 2 is installed on the rack and is used to clamp the battery and pressurize it while contacting the tab of the battery;

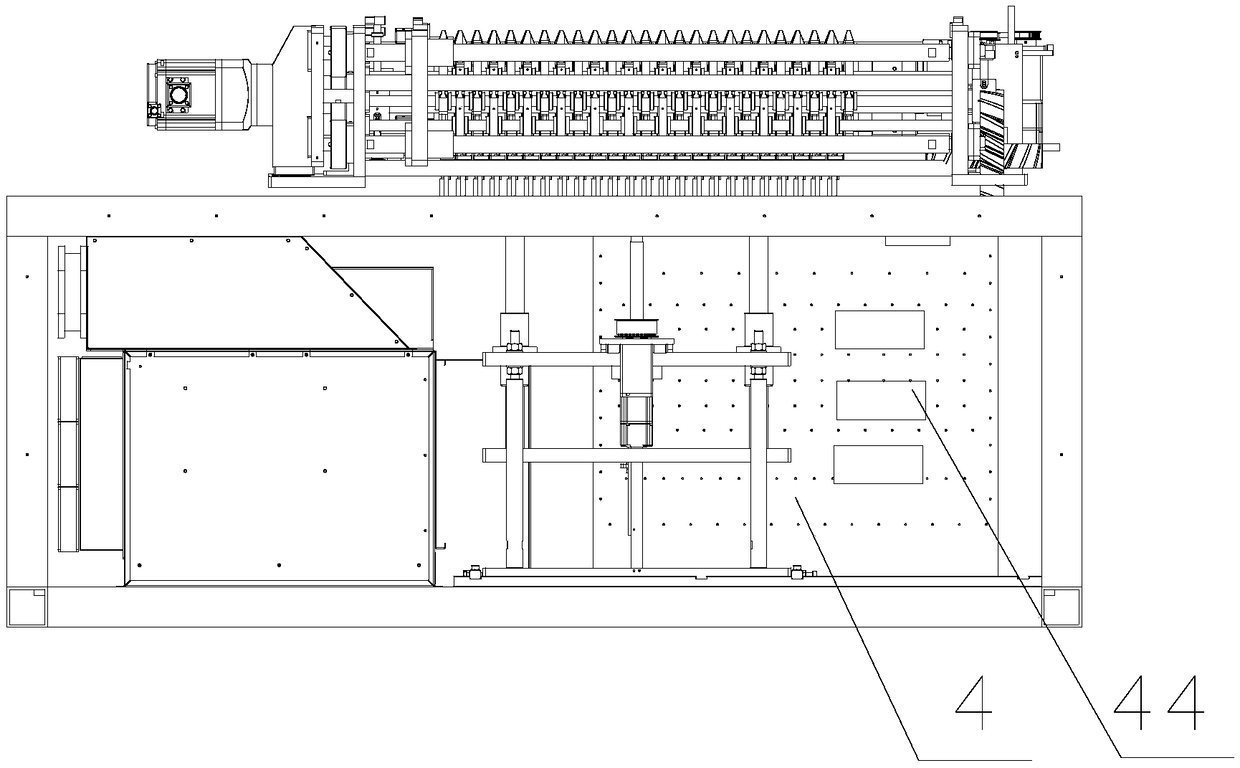

[0046] The battery support adjustment mechanism 3 is installed on the frame and located directly below the battery, and is used for automatic type change and support for the battery according to the type of the battery;

[0047] The temperature control mechanism 4 is installed on the frame and is used to heat the battery clamped on the automatic clamping device;

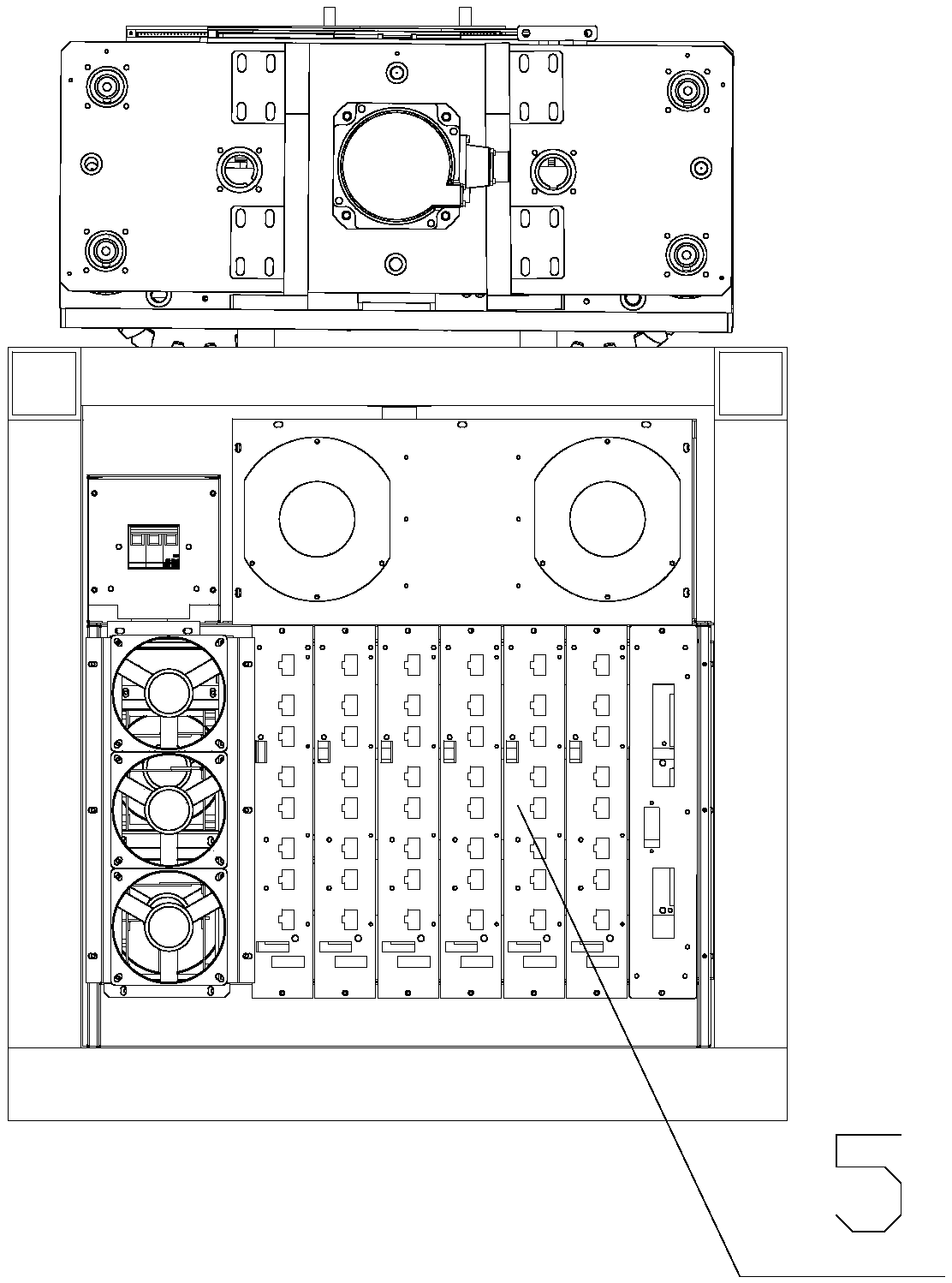

[0048] The battery forming cabinet 5 is installed on the rack and is in contact with the battery tabs for charging and discharging the batteries;

[0049] And a controller, installed on the frame, and electrically connected with the automatic clamp mechanism, the battery support adjustment mechanism and the temperature contro...

Embodiment 2

[0058] Example 2 as Figure 1 to Figure 17 As shown, the fully automatic battery formation fixture machine of the present invention includes a frame 1, an automatic fixture mechanism 2, a battery support adjustment mechanism 3, a temperature control mechanism 4 and a battery formation cabinet 5. The automatic clamp mechanism 2 , the battery support adjustment mechanism 3 , the temperature control cabinet 4 and the battery formation cabinet system 5 are all installed on the frame 1 . The automatic clamp mechanism 2 is a set of mechanisms for pressurizing the battery 7, and the battery support adjustment mechanism 3 is a set of movement mechanisms for supporting the battery 7 with the automatic clamp mechanism 2. Multiple batteries 7 can be placed at a time, and can be adjusted according to the battery. A set of mechanisms for automatic type change with a width of 7. During the production process, the battery will be put into the battery support adjustment mechanism 3. After th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com