A substrate supporting member and a substrate conveying device

A substrate support and conveying device technology, which is applied to electrical components, conveyor objects, transportation and packaging, etc., can solve the problems of difficult support height, heavy workload, and difficult adjustment, so as to improve the adjustment difficulty and reduce the Workload and the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] This application provides a substrate support and a substrate transfer device. In order to make the purpose, technical solution and technical effect of this application clearer and clearer, the following will further describe this application in detail. It should be understood that the specific implementation regulations described here are only for explanation This application is not intended to limit this application.

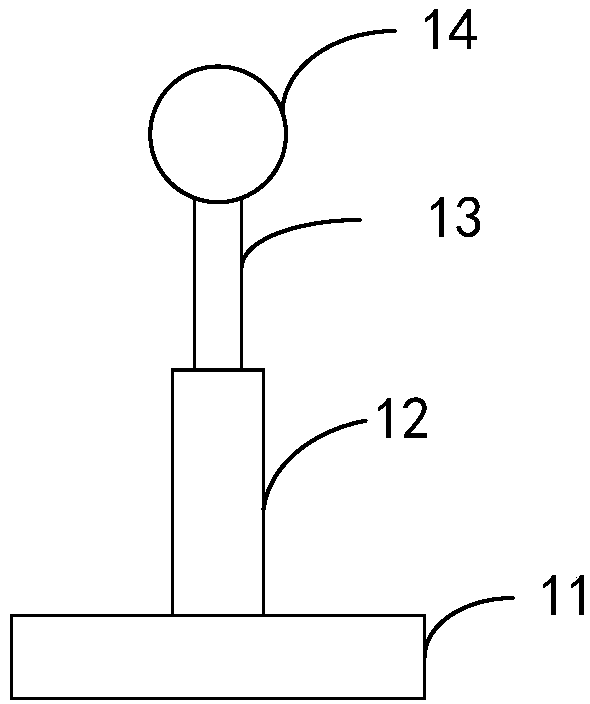

[0013] Substrate supports are generally included in substrate transfer and processing equipment to assist in supporting the substrate during substrate transfer processing. Such as figure 1 as shown, figure 1 It is a structural schematic diagram of the substrate support in the prior art. The height of the substrate support in the prior art needs to be manually adjusted. Specifically, the substrate support includes a base 11, a first connecting rod 12, and a second connecting rod 13 , guide wheel 14, wherein the first connecting rod 12 and the second co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com