A Quick Calculation Method for Installation Clearance of Two-section Shaft

A fast calculation and installation clearance technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of increased cost, difficult disassembly and assembly, and high cost of high-precision coaxial parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The following are specific embodiments of the present invention, and the solutions of the present invention will be further described with reference to the accompanying drawings, but the present invention is not limited to these embodiments.

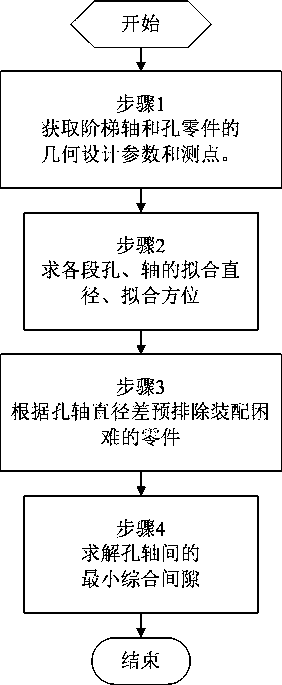

[0069] The fast calculation method for the installation clearance of two shafts consists of the following four steps (unit: mm, radian):

[0070] Step 1, get the measurement point.

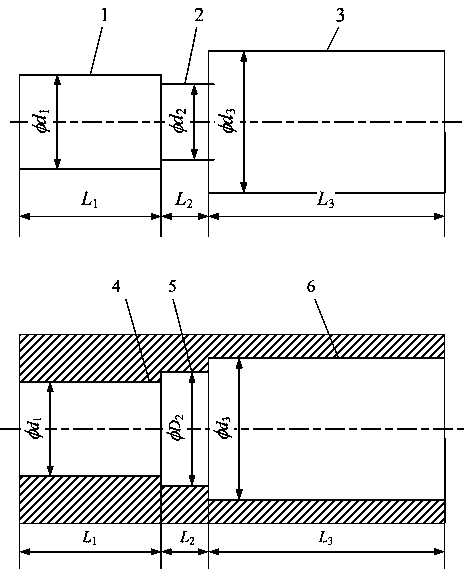

[0071] The stepped shaft is composed of a thin shaft and a thick shaft, and a transition shaft is connected between the thin shaft and the thick shaft.

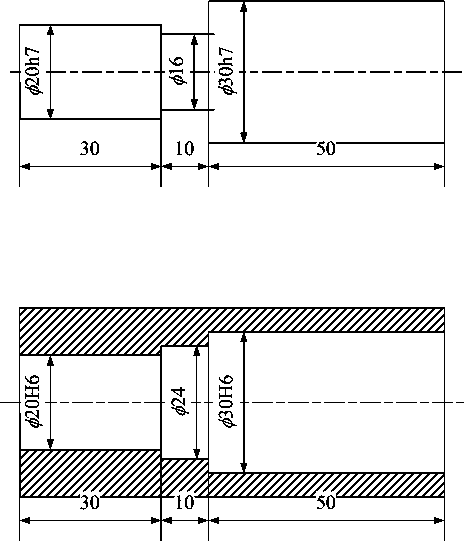

[0072] The nominal diameter of the thin shaft is 20 and the nominal length is 30; the nominal diameter of the transition shaft is 16 and the nominal length is 10; the nominal diameter of the thick shaft is 30 and the nominal length is 50.

[0073] The nominal diameter 30 of the thick shaft is greater than or equal to the nominal diameter 20 of the thin shaft; the nominal diameter 16 of the transitio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com