A device for locating the spatial direction of the core in the hole and a method for verifying the casing stress relief method

A technology of spatial direction and positioning device, which is applied in earthwork drilling, wellbore/well components, measurement and other directions, which can solve the problems of difficult operation and achieve the effect of simple operation, high precision and simple and easy test method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

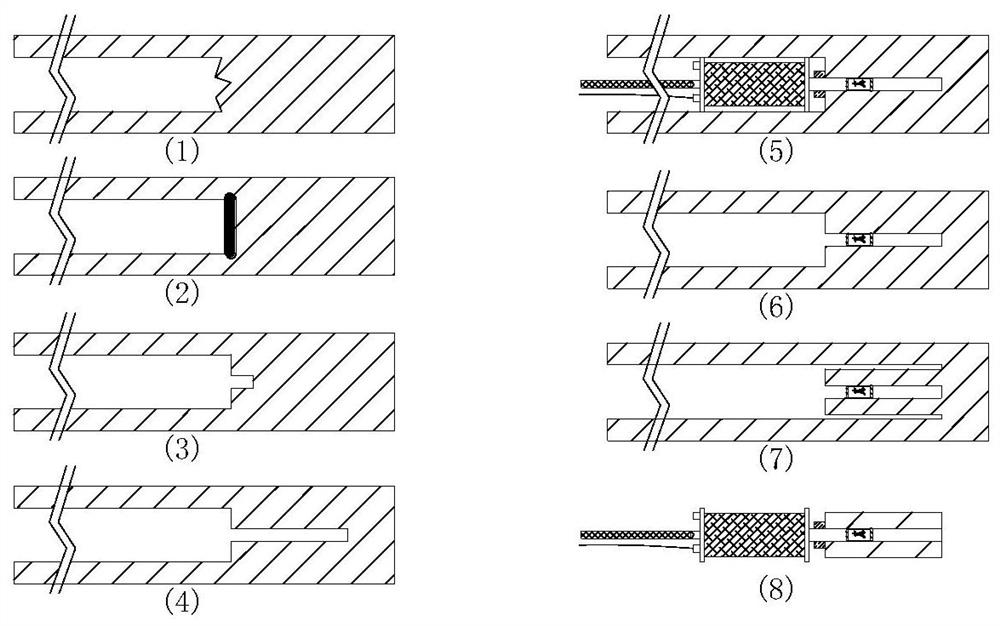

[0036]The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

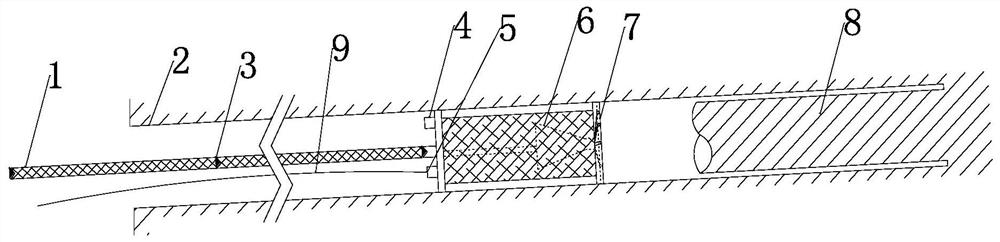

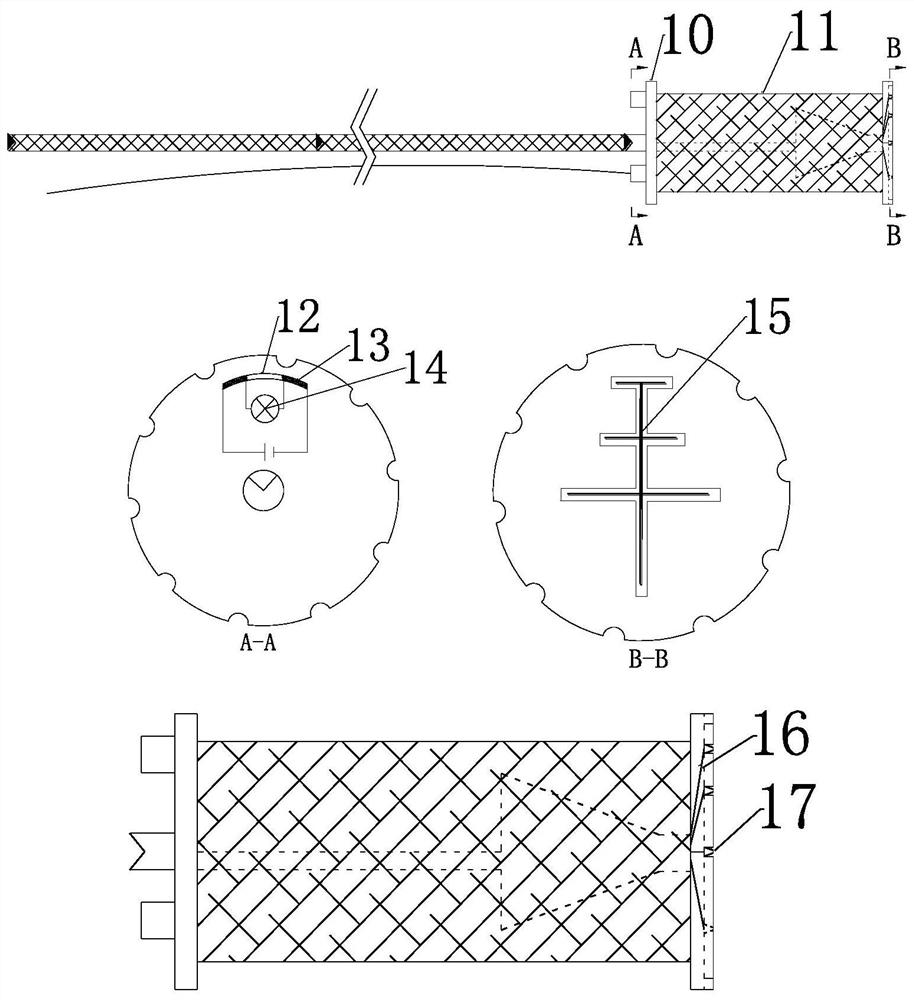

[0037] figure 1 The present invention provides a schematic diagram of a method based on in-hole core marking and orientation technology using casing stress relief method to verify the reliability of original hole core test results, which is suitable for spatial orientation measurement of unbroken core in holes. The device includes a bamboo-style installation rod 1 , a horizontal orientation device 4 , a marking liquid holding box 6 , a high-pressure air pipe 9 , and a thick-walled copper cylinder 11 .

[0038] The rear end of the thick-walled copper cylinder 11 is equipped with a high-pressure air pipe interface 5, and the high-pressure air pipe interface 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com