Laminated sawing machine

A stacked, sawing machine technology, applied in circular saws, sawing components, sawing equipment, etc., to achieve the effects of convenient processing, increased safety, and labor cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

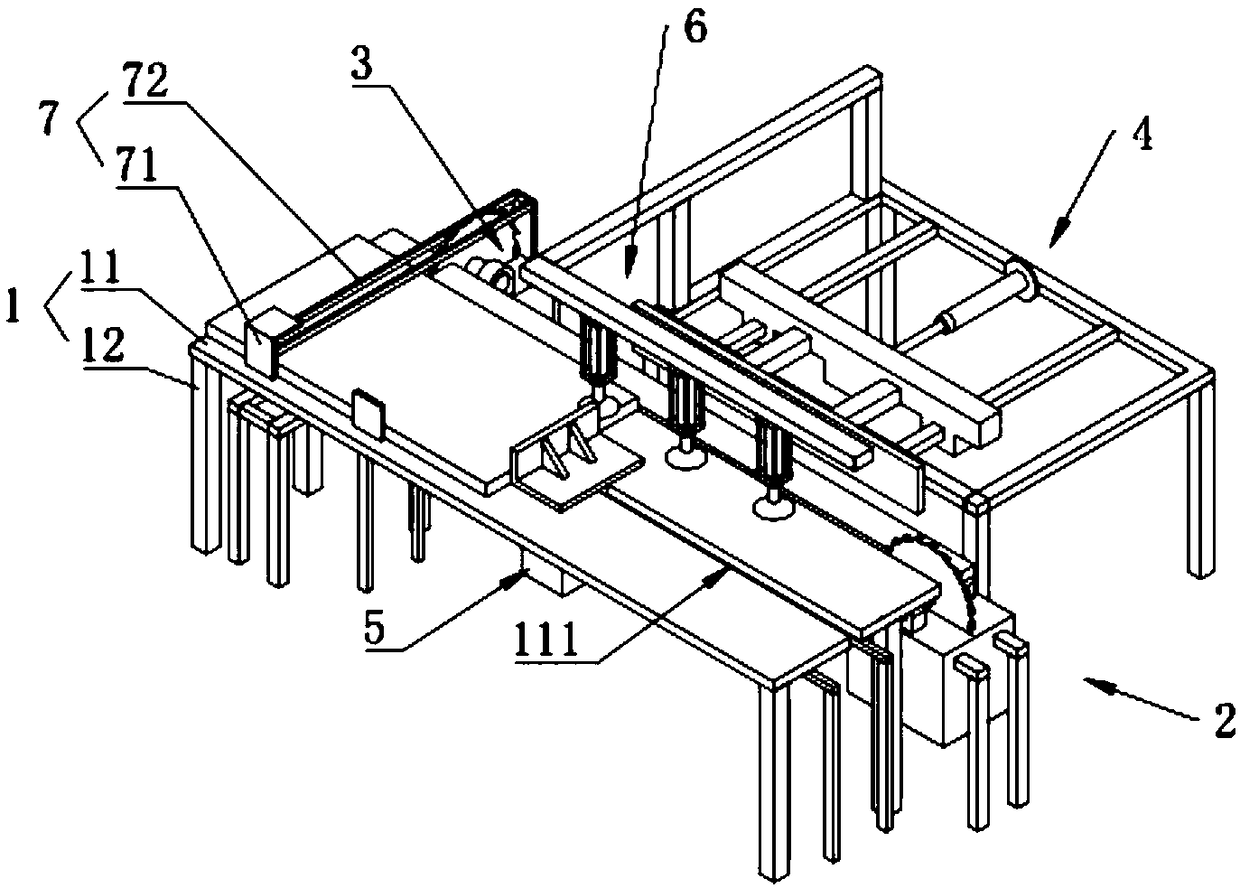

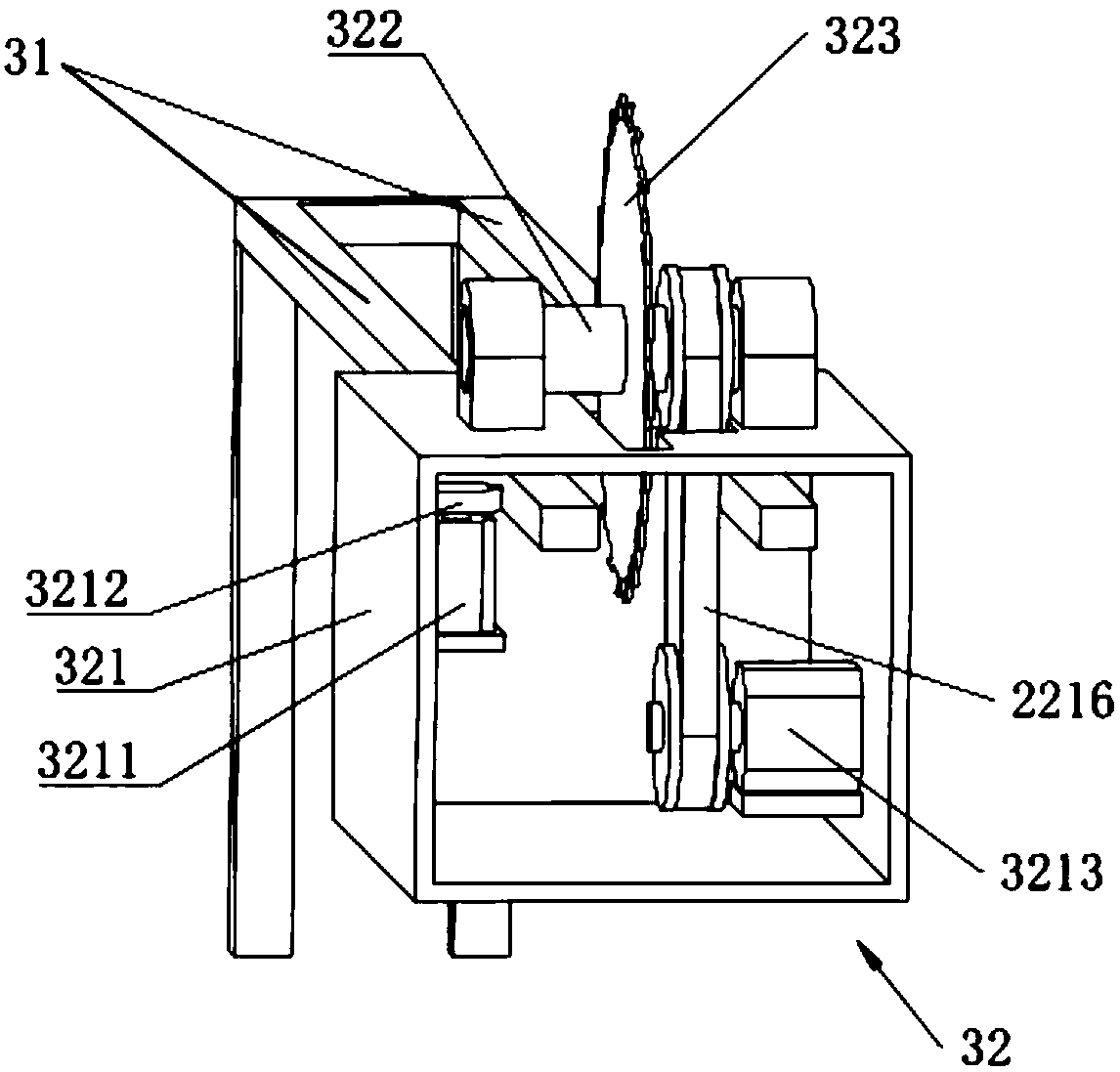

[0030] A stack sawing machine, such as figure 1 As shown, the frame 1, the transverse sawing device 2, the transverse propulsion device 4, the longitudinal sawing device 3, the longitudinal propulsion device 5 and the pressing device 6, wherein the frame 1 plays a role in supporting the equipment and the plank, The transverse sawing device 2 and the transverse propulsion device 4 work together to saw the wood into a plate with a suitable width, and the longitudinal sawing device 3 and the longitudinal propulsion device 5 process the plank again to form a shaped product with a suitable length.

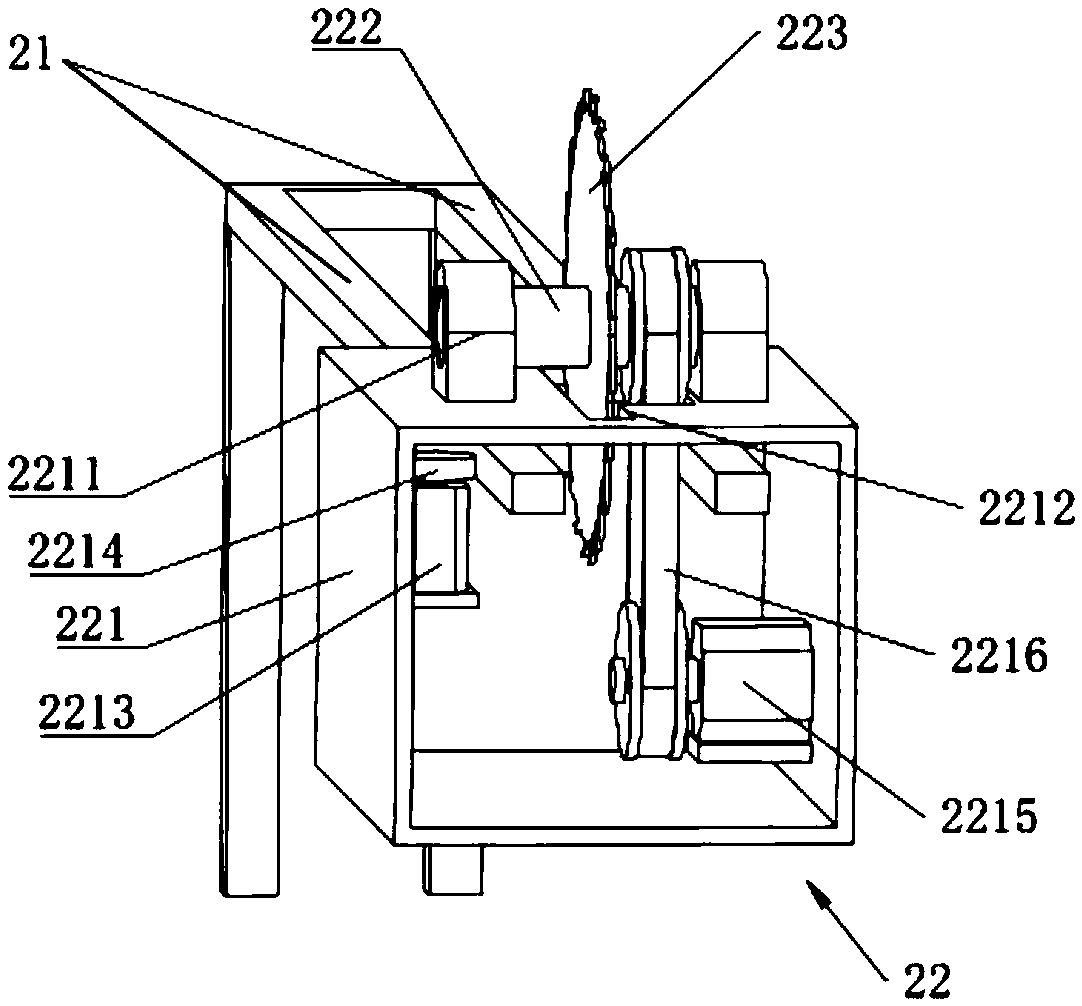

[0031] combine figure 1 and figure 2 , The frame 1 includes a support board 11 and a foot 12 for supporting the support board 11 , the support board 11 is kept horizontal, and the wood sawing process is performed on the support board 11 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com