A soil remediation device for soil polluted by heavy metals

A soil remediation and polluted soil technology, applied in the restoration of polluted soil, etc., can solve problems such as weak reproductive capacity, low repair efficiency, soil pollution, etc., and achieve the effects of improving equipment mobility, improving processing efficiency, and improving soil fertility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

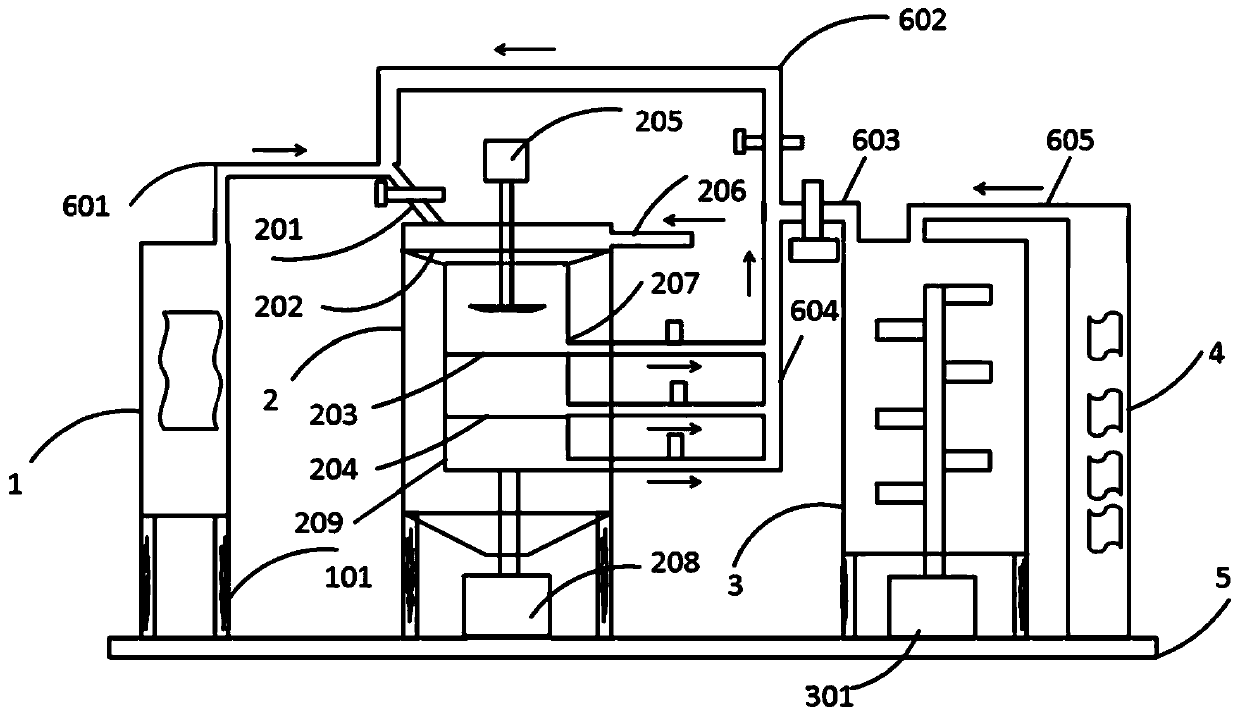

[0035] refer to figure 1 , the present invention includes mud tank 1, rinse tank 2, dry-wet mixer 3, sludge dehydration and drying device 4; Sludge outlet pipe 604, sludge dehydration and drying sludge pipe 605; the soil to be treated is put into the mud tank 1, and after the mud preparation is completed, it enters the rinsing tank through the mud inlet pipe 601 for rinsing, and the sludge after rinsing Discharge into the dry-wet sludge mixer 3 through the rinsing sludge outlet pipe 604; the remaining sludge after being treated by the sludge dehydration and drying device enters the dry-wet sludge mixer 3 through the dehydration and drying sludge pipe 605 and drenches The washed sludge is mixed, and the mixed sludge is discharged;

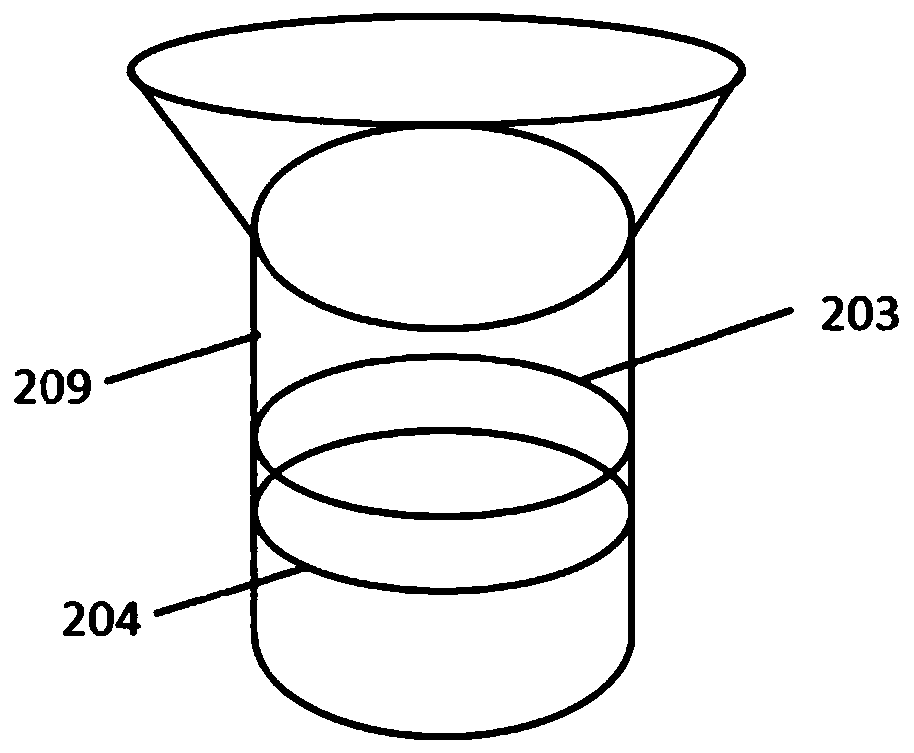

[0036]The upper part of the rinsing tank is provided with a horizontal filter screen 202, and when the mud inlet pipe 201 arranged on the top of the rinsing tank passes the mud into the rinsing tank, the filter screen 1 performs preliminary filtrat...

Embodiment 2

[0045] The specific embodiment is the same as Example 1, the difference is that the soil is polluted by cadmium (0.08-0.15g / kg), and the organic complexing agent EDTA of concentration 0.2mol / L, oxalic acid of concentration 0.15-0.23mol / L, 0.1-0.25 The concentration of mercury ions in the soil decreased by 86.8% after the mol / LKI solution was treated with three kinds of leaching agents sequentially and mixed with the remaining sludge for composting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com