Ultrasonic cleaning machine used for production of LED lamp

The technology of an ultrasonic cleaning machine and LED lights is applied in the direction of cleaning methods using liquids, cleaning methods and utensils, chemical instruments and methods, etc., which can solve the problems of large footprint, complex structure, and prone to mechanical failures, and achieve structural Simple, not easy to mechanical failure, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

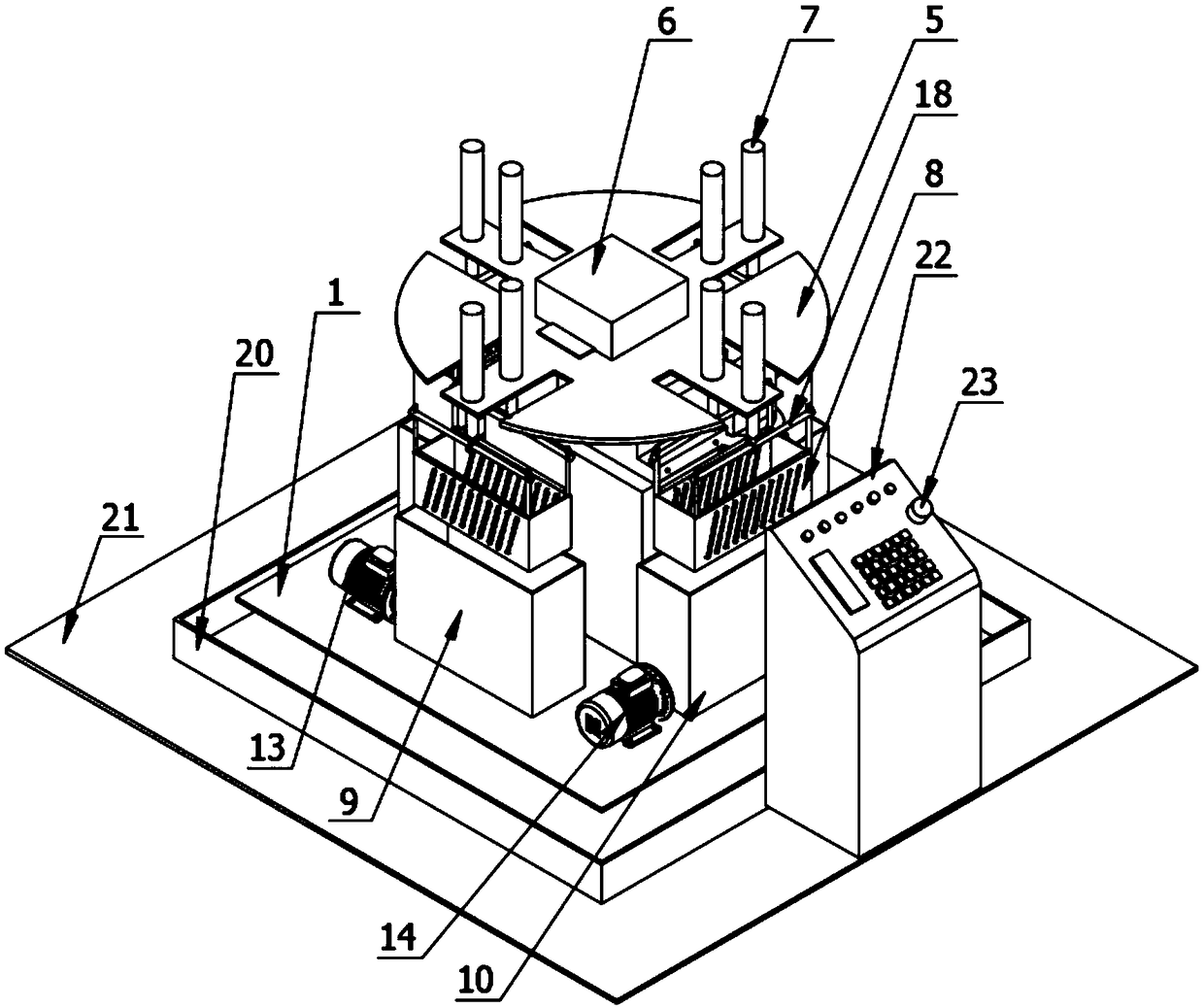

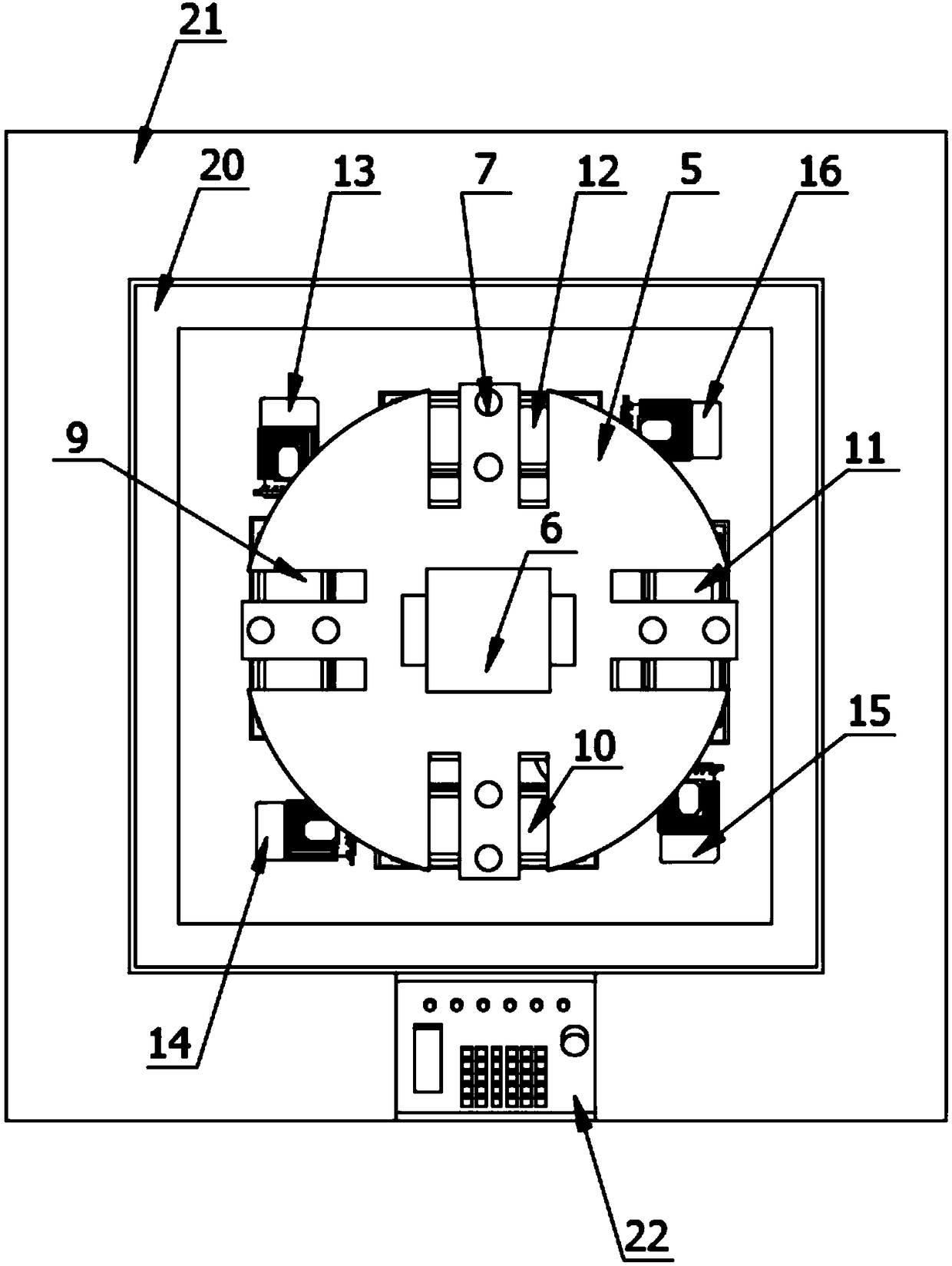

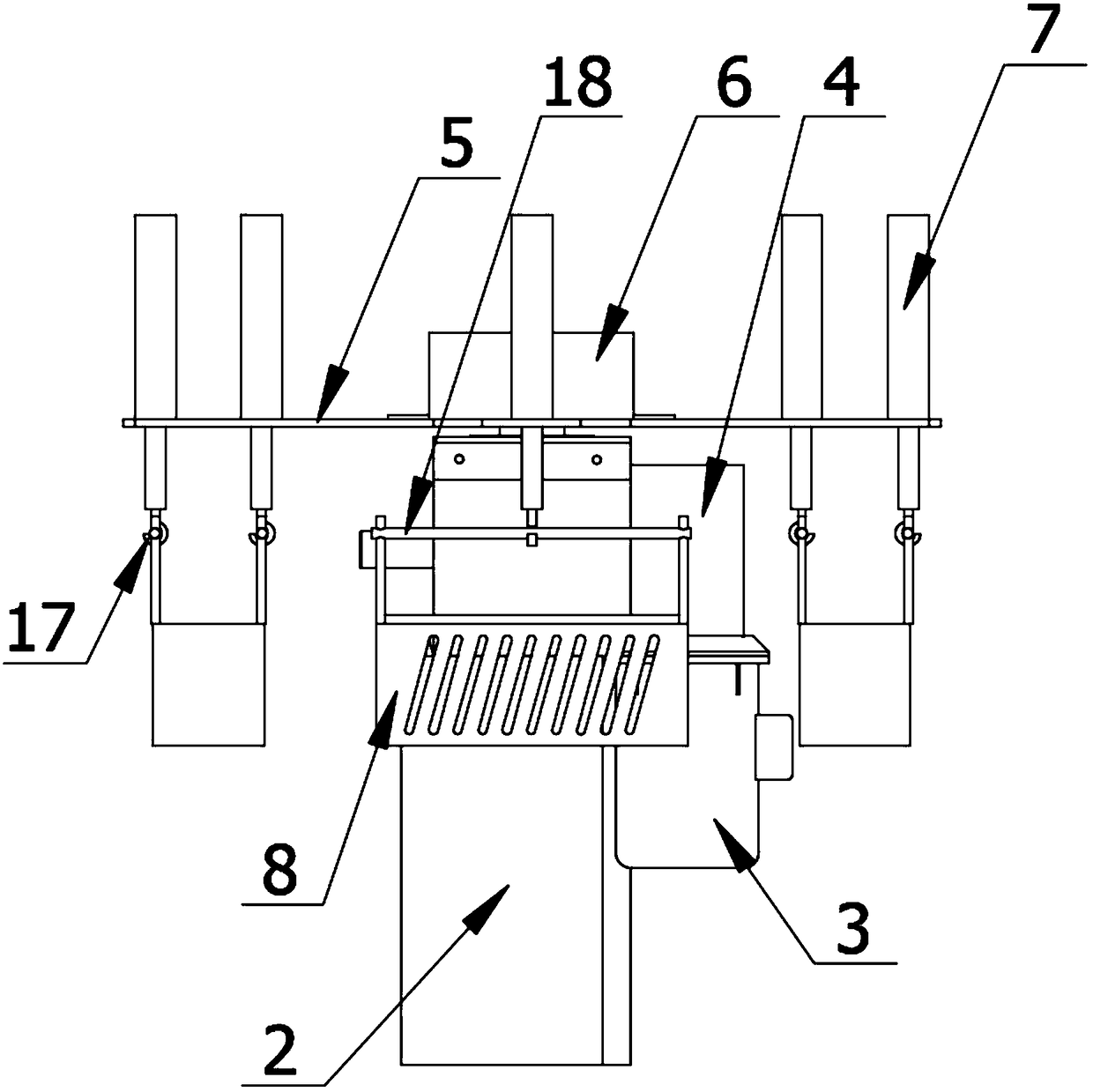

[0019] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5 As shown, an ultrasonic cleaning machine for LED lamp production includes a rotary lifting device, a cleaning device, a base 1 and a control circuit. The servo motor 3 on the motor base 2, the reducer 4 connected to the main shaft of the servo motor 3, the index turntable 5 arranged on the output shaft of the reducer 4, and the index turntable 5 arranged at the center of the index turntable 5 Cable box 6, the indexing turntable 5 is a common carrying tool for mechanical processing, and a special indexing turntable 5 can be customized according to actual needs. The indexing turntable 5 described in this device is provided with four synchronous electric push rods 7 installation positions, for the installation of the synchronous electric push rod 7, the power supply mode that the reducer 4 is connected with the servo motor 3 is used to control the rotation and sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com