Agricultural all-directional water spraying and fertilizer application equipment

An all-round, agricultural technology, applied in agriculture, fertilization devices, applications, etc., can solve the problems of fertilizer waste, incomplete melting and mixing of fertilizer and water, and no pre-pulverization, etc., to expand the spraying range, high spraying efficiency, and spraying full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

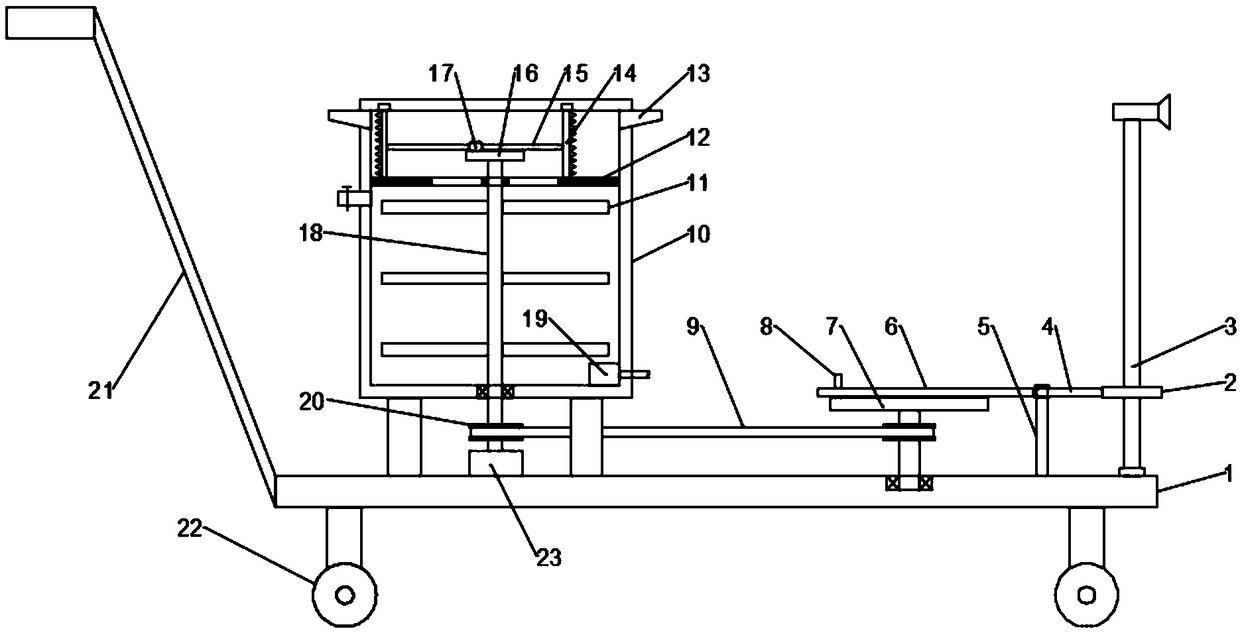

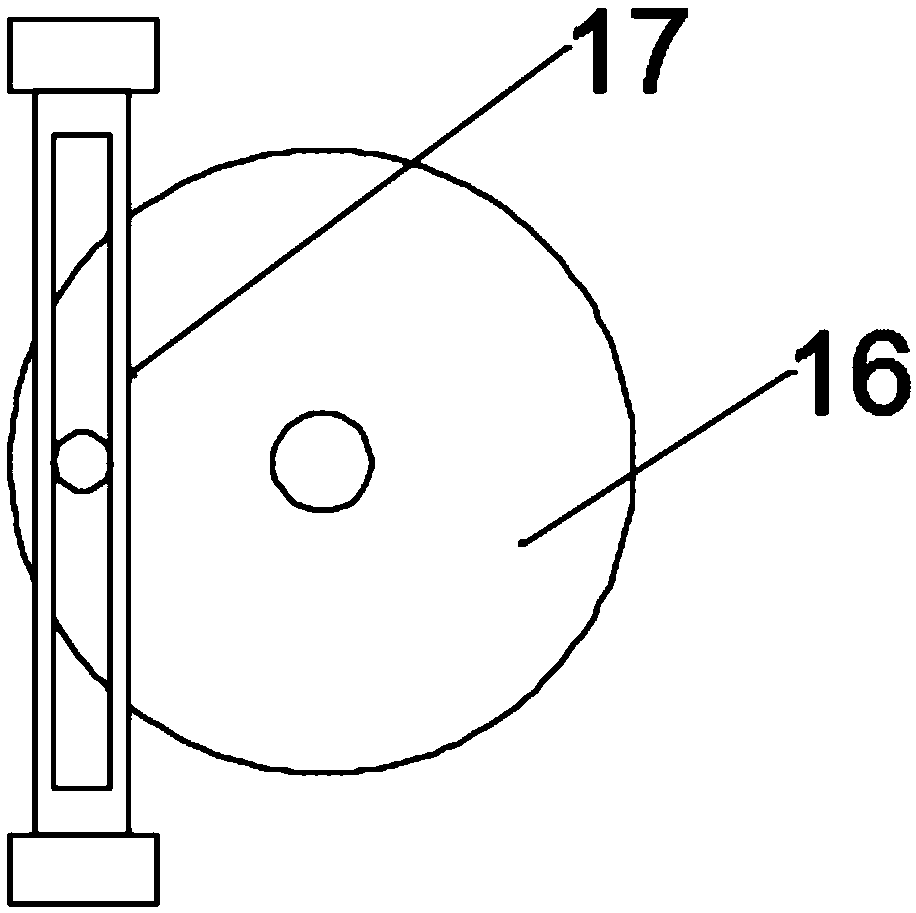

[0022] see Figure 1~3 , in the embodiment of the present invention, an all-round sprinkling and fertilizing equipment for agriculture, including a base plate 1, a preparation device and a sprinkler device, the bottom of the base plate 1 is equipped with an anti-skid wheel 22 through the supporting legs, and one end of the base plate 1 is welded and fixed with a handrail 21. A preparation device is installed on one side of the upper surface of the substrate 1. The preparation device includes a water tank 10, a stirring shaft 18, a motor 23 and a crushing mechanism. The water tank 10 is installed above the substrate 1, and the upper part of the inner cavity of the water tank 10 is welded and fixed There is a baffle, and the screen 12 is installed with screws on both sides of the baffle, and there are installation holes for the screen 12 to be installed on the baffle. The shaft is connected to the stirring shaft 18 through a coupling, the stirring shaft 18 runs through the botto...

Embodiment 2

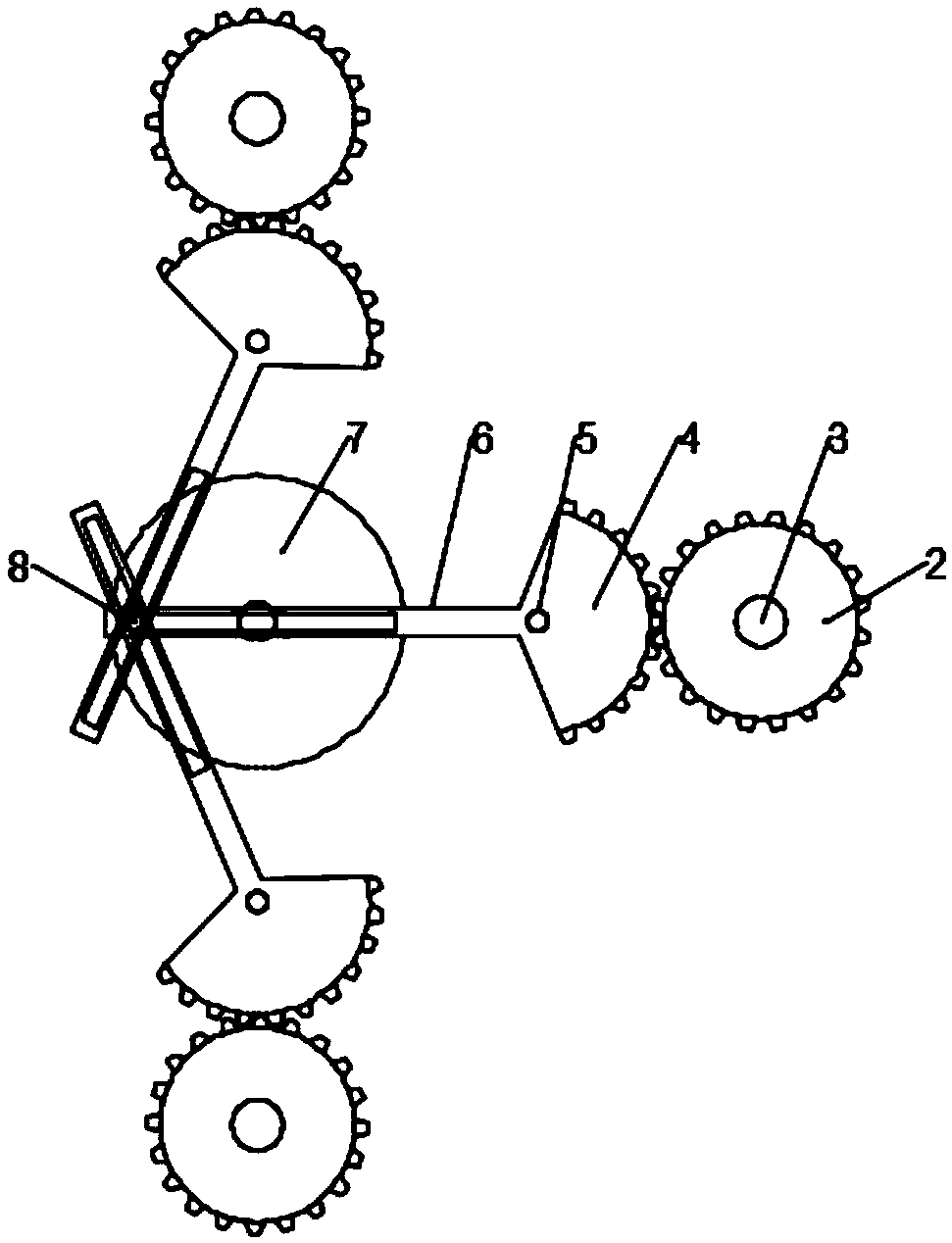

[0027] see Figure 4~5, The difference between this embodiment and Embodiment 1 is that the sprinkler device includes a third disk 28, a connecting rod 27, a mounting plate 26, a rack 24, a gear 2, a mounting rod 3 and a sprinkler head, and the third Disc 28 is installed on the top of the vertical installation shaft, and the vertical installation shaft is rotatably connected with base plate 1 through bearings. Belt pulley 20 is installed on the vertical installation shaft and stirring shaft 18, and the two on the vertical installation shaft and stirring shaft 18 A belt 9 is connected between the pulleys 20, a connecting rod 27 is hinged on the outside of the upper end surface of the third disk 28, and a mounting plate 26 is hinged on the other end of the connecting rod 27. The bottom of the mounting plate 26 is provided with a third slide block 25, the third slide block 25 is slidingly connected with the upper part of the base plate 1, and three racks 24 are installed on the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com