Engine electronic control redundant system

A redundant system and engine technology, applied in the direction of engine control, electrical control, combustion engine, etc., can solve problems such as inability to diagnose, potential safety hazards, and potential safety hazards in the engine, so as to improve work stability, prevent major failures, and ensure stability. running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the specific embodiments in the drawings.

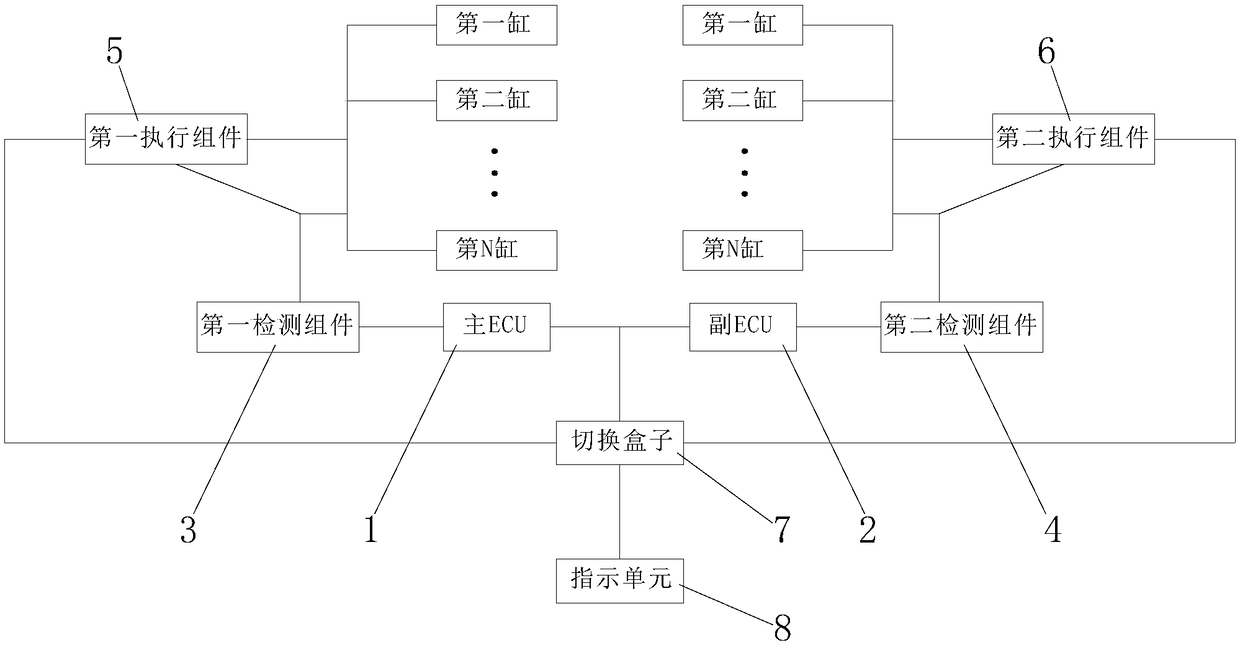

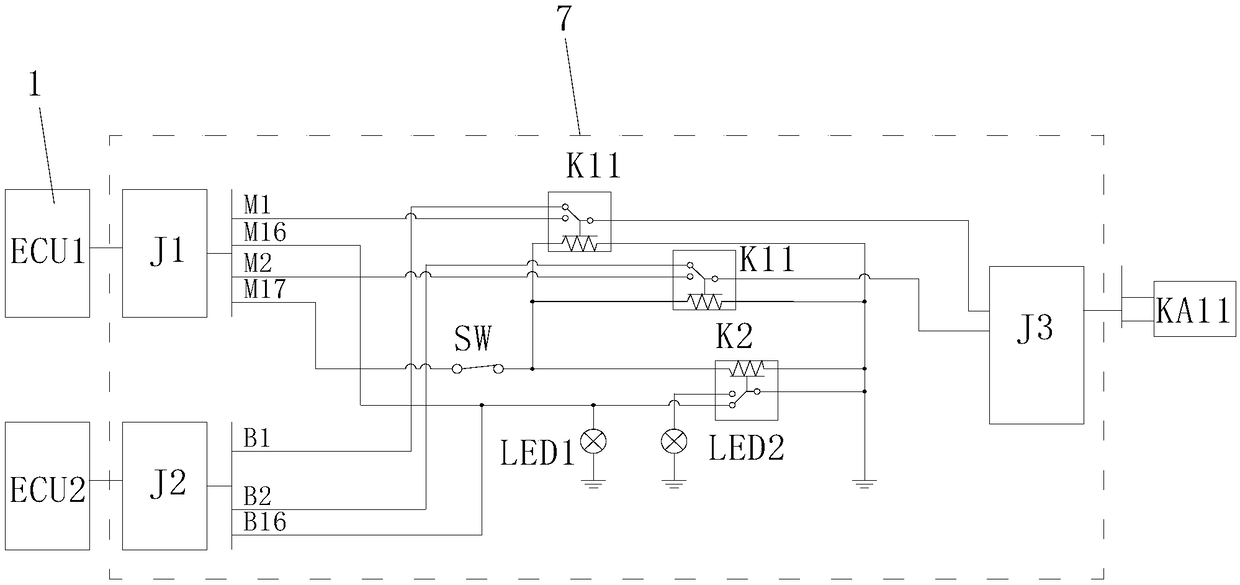

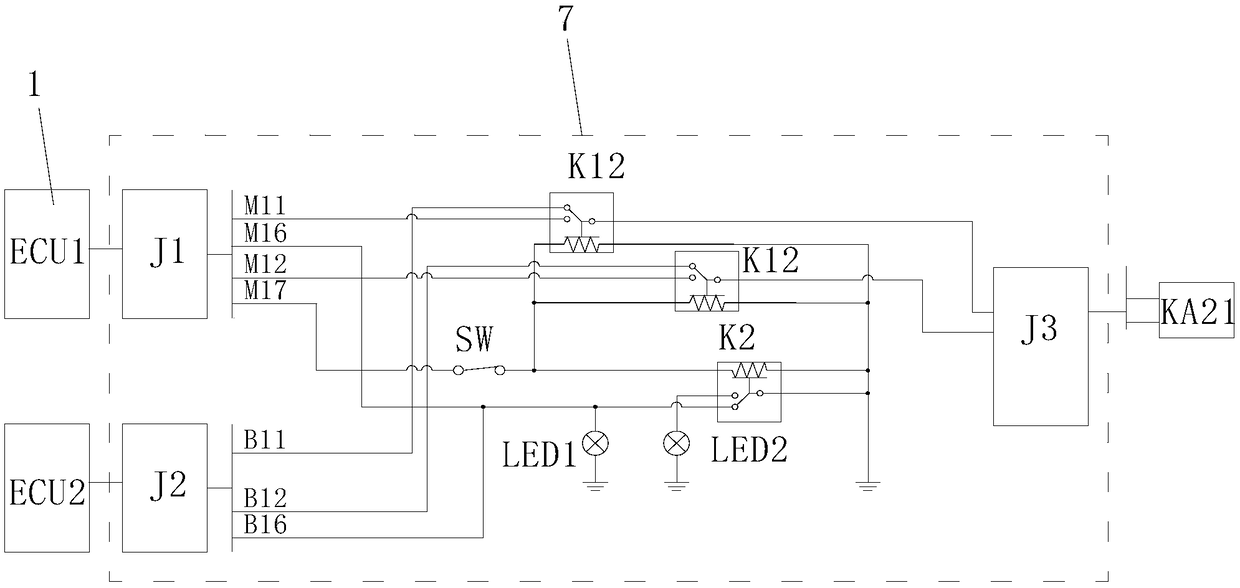

[0019] Refer to Figure 1-3 , An engine electronic control redundant system, including a main ECU1, a secondary ECU2, a first detection component 3 and a second detection component 4 for monitoring the parameters on both sides of the V-type internal combustion engine, respectively, for controlling the two sides of the V-type internal combustion engine Working first executive component 5 and second executive component 6, switching box 7 for switching control signals of main ECU1 and sub-ECU2; first detection component 3 signal output terminal is connected with main ECU1 signal input terminal, second detection component 4 The signal output terminal is connected to the signal input terminal of the secondary ECU2. The control signal output terminal of the main ECU1 is connected to the control terminals of the first executive assembly 5 and the second executive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com