Automatic eye pad packaging equipment

An automatic packaging and eye patch technology, applied in packaging, packaging machines, packaging protection and other directions, can solve the problems of cumbersome operation process, low work efficiency, inability to achieve fully automated production, etc., to improve work efficiency, improve efficiency, and reduce labor. the effect of participation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

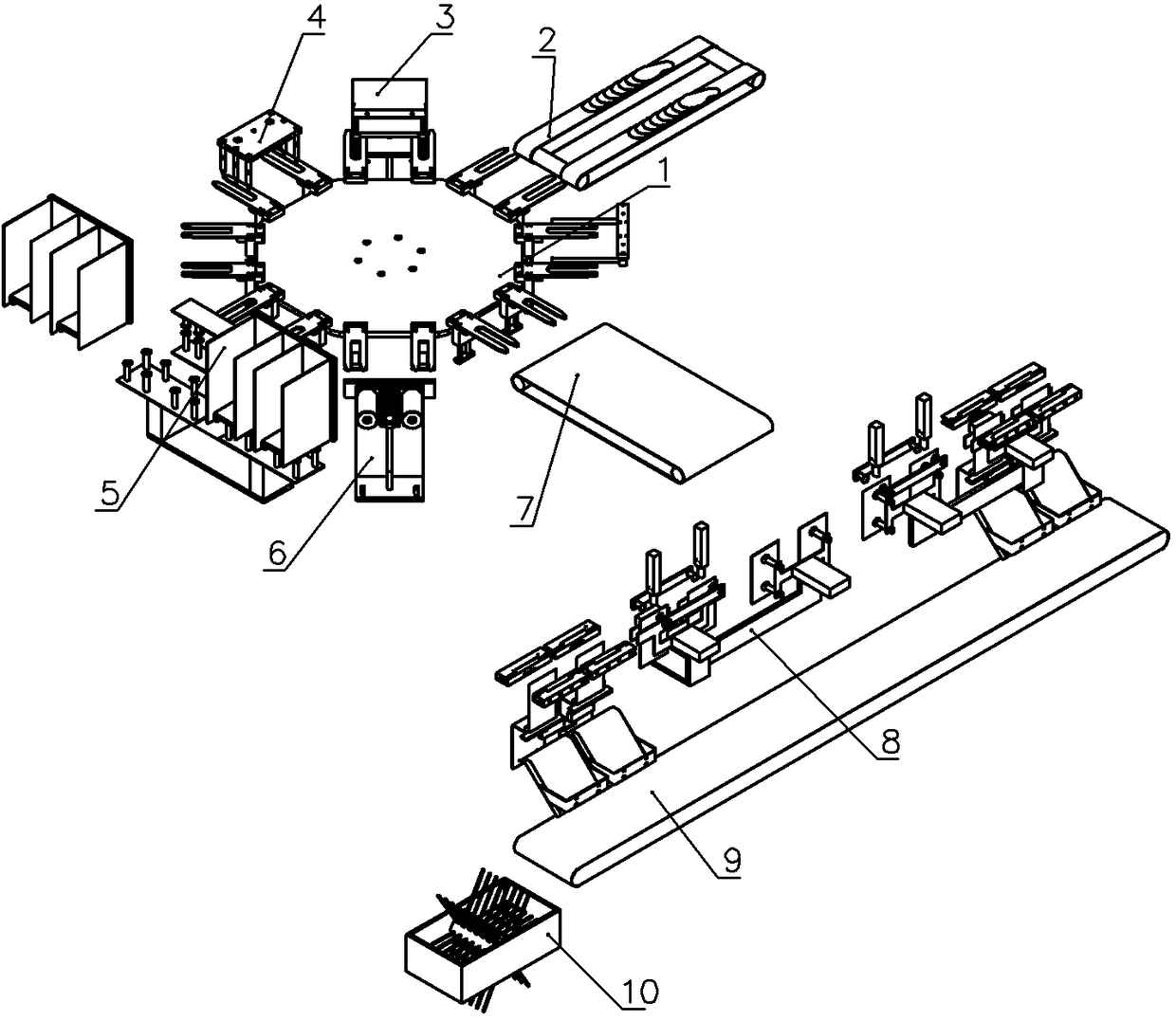

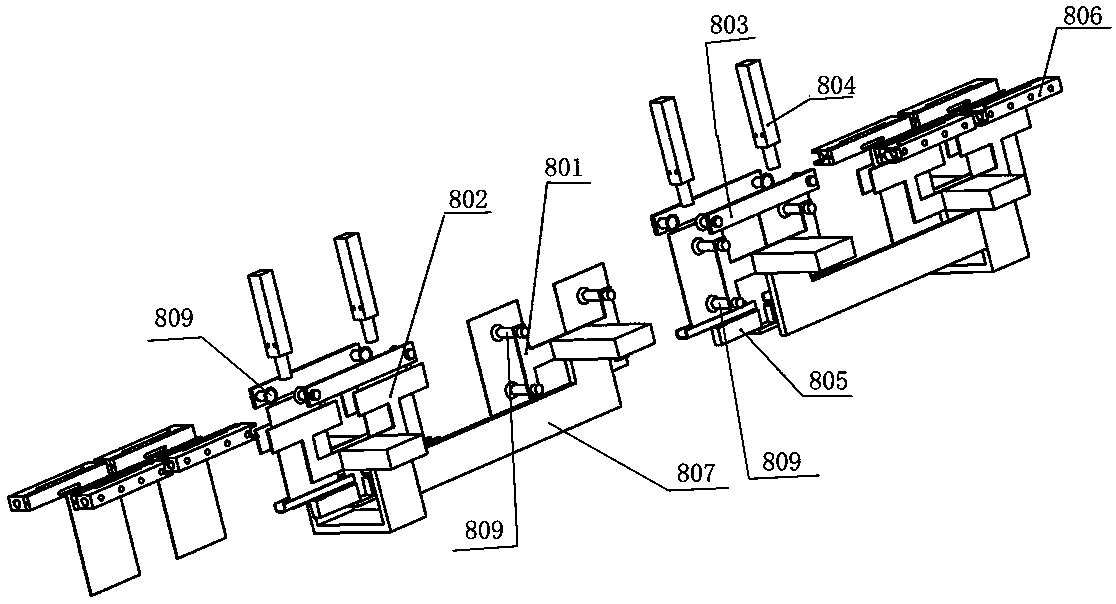

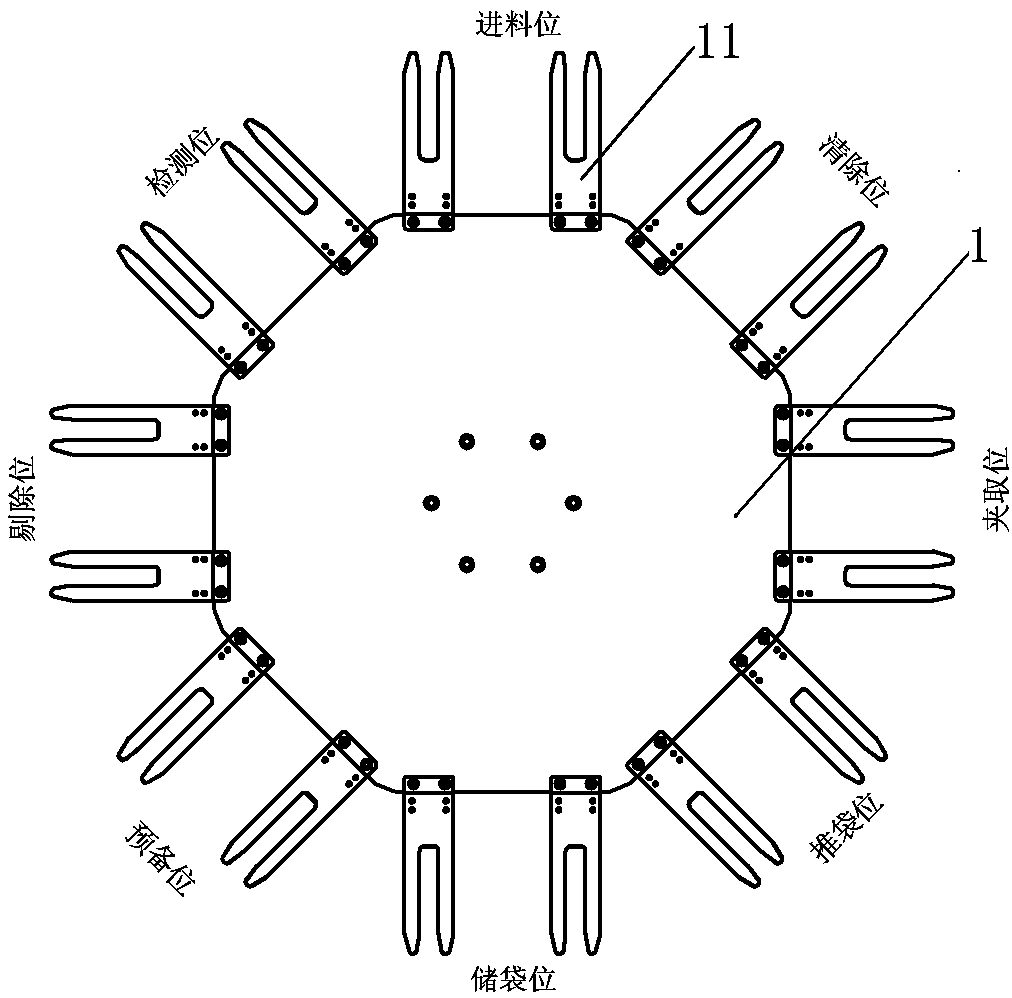

[0023] Example: see figure 1 , figure 2 , image 3 and Figure 4 , in the figure, 1-rotary table, 2-feeding mechanism, 3-detection mechanism, 4-rejection mechanism, 5-bag storage mechanism, 6-push bag mechanism, 7-clamping mechanism, 8-two-way horizontal Moving filling mechanism, 9-discharging conveying mechanism, 10-collecting mechanism, 11-clamping device, 12-eye patch bag body;

[0024] 111-upper clip, 112-clamp body fixing block, 113-lower clip, 114-sliding rod, 115-limiting plate, 116-return spring, 117-bar hole;

[0025] 801-Bag taking mechanism, 802-Exhausting mechanism, 803-Opening mechanism, 804-Filling mechanism, 805-Weighing mechanism, 806-Sealing mechanism, 807-Connecting plate, 809-Vacuum suction cup.

[0026] Automatic packaging equipment for eye stickers, including a bracket and a rotary table 1 arranged on the bracket. Eight work stations are arranged in a ring on the support around the rotary table 1, and the rotary table 1 corresponding to each station a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com