Drilling and shaping device of a coated explosive column

A technology of shaping device and powder column, which is applied in metal processing, smoke and dust removal, cleaning methods and utensils, etc., can solve the problems of no instructions or reports, no data collected, etc., and achieve the effect of simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

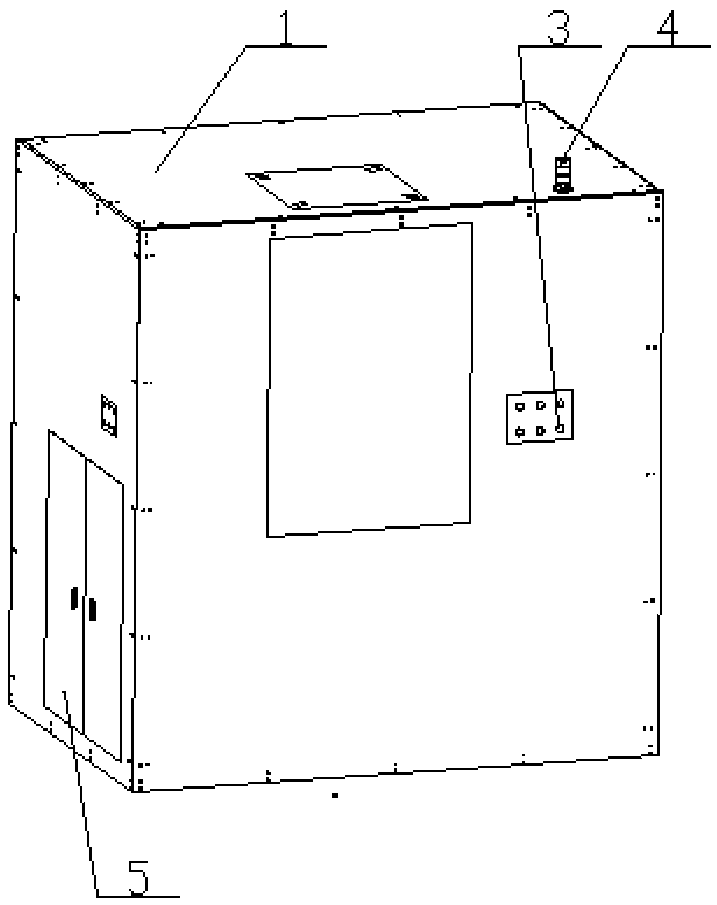

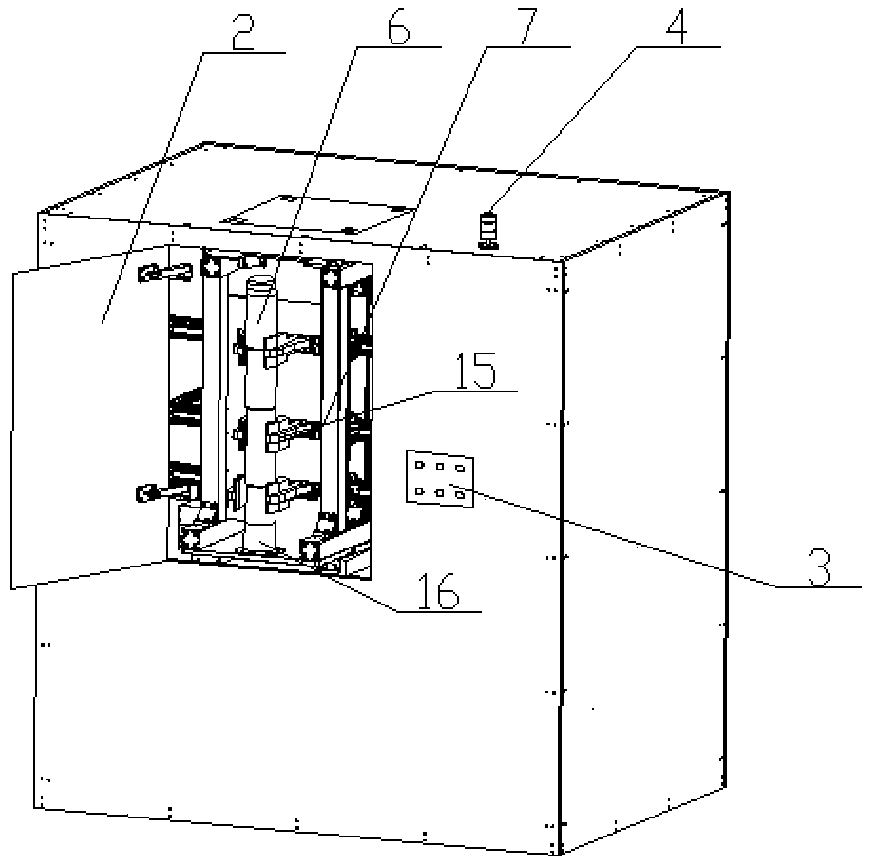

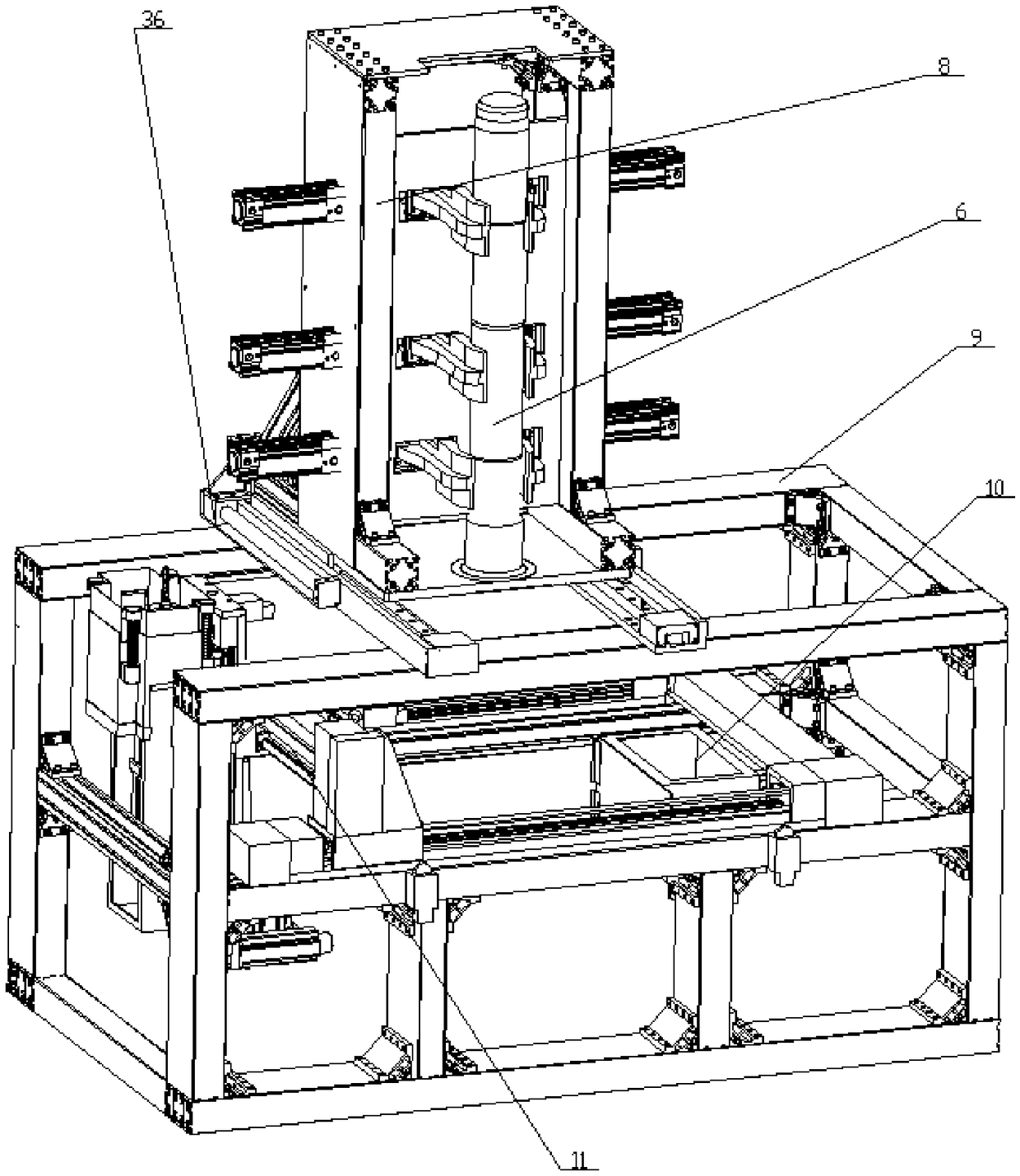

[0042] figure 1 It is a structural diagram of the overall appearance of the device according to the embodiment of the present invention; figure 2 It is a structural diagram of the overall appearance of the device according to the embodiment of the present invention for opening the door and loading materials; image 3 It is a structural diagram of the internal kinematic mechanism assembly of the device according to an embodiment of the present invention; Fig. 4 (a) and Fig. 4 (b) are a structural diagram of a claw assembly of a device according to an embodiment of the present invention; Fig. 5 (a) and Fig. 5(b) is a structural diagram of the camera assembly of the device according to the embodiment of the present invention; FIG. 6(a) and FIG. 6(b) are structural diagrams of the Cartesian coordinate mechanism of the device according to the embodiment of the present invention; Figure 7 is a plan view of the Cartesian coordinate mechanism of the device according to the embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com