Method for making multi-functional edentulous and lipless impression tray

A technology of impression tray and production method, applied in dentistry, stamping cup, dental prosthesis, etc., can solve the problems of complicated operation, recording deviation, poor accuracy, etc., to simplify operation steps, reduce operation difficulty, and improve diagnosis and treatment The effect of efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

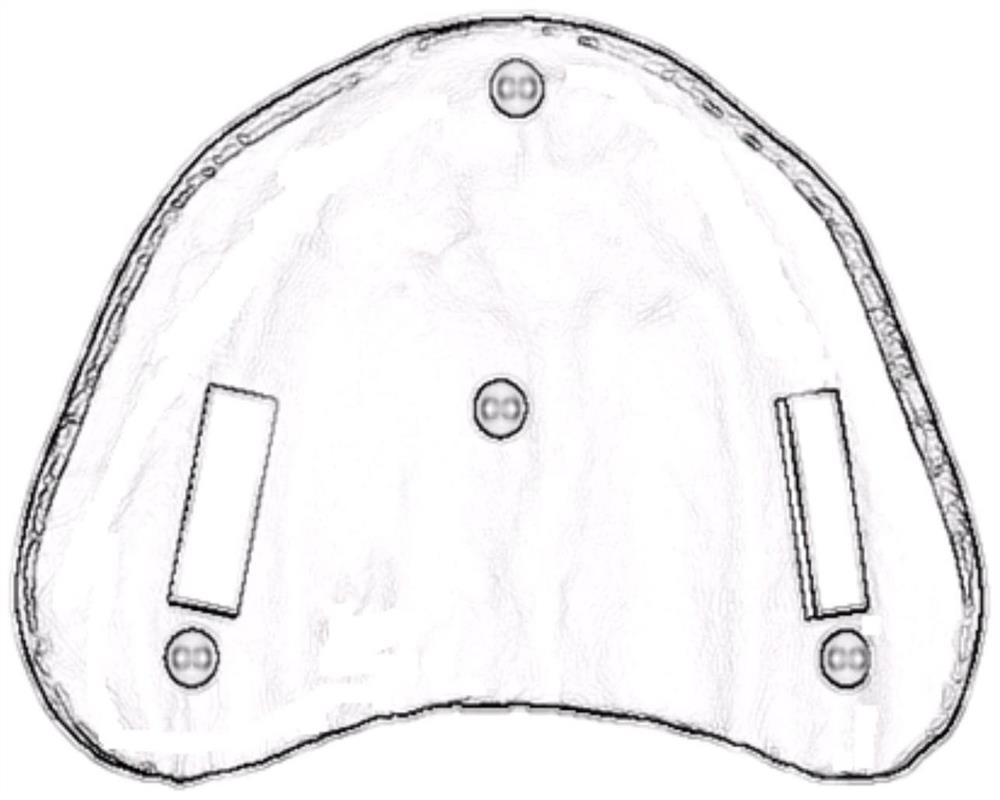

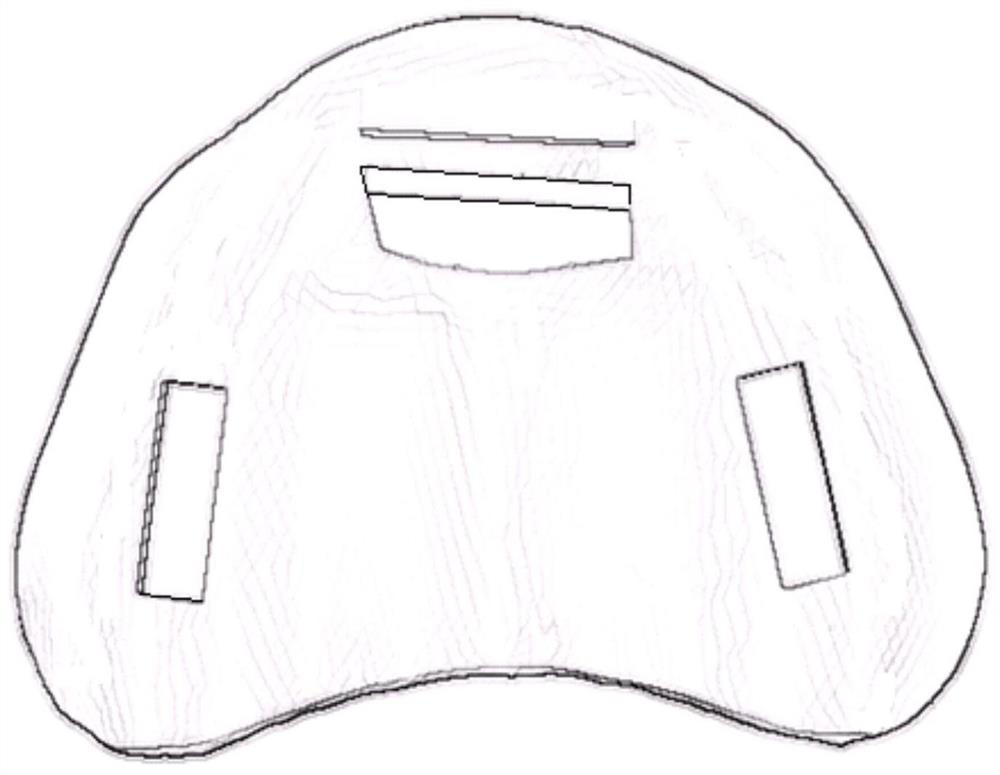

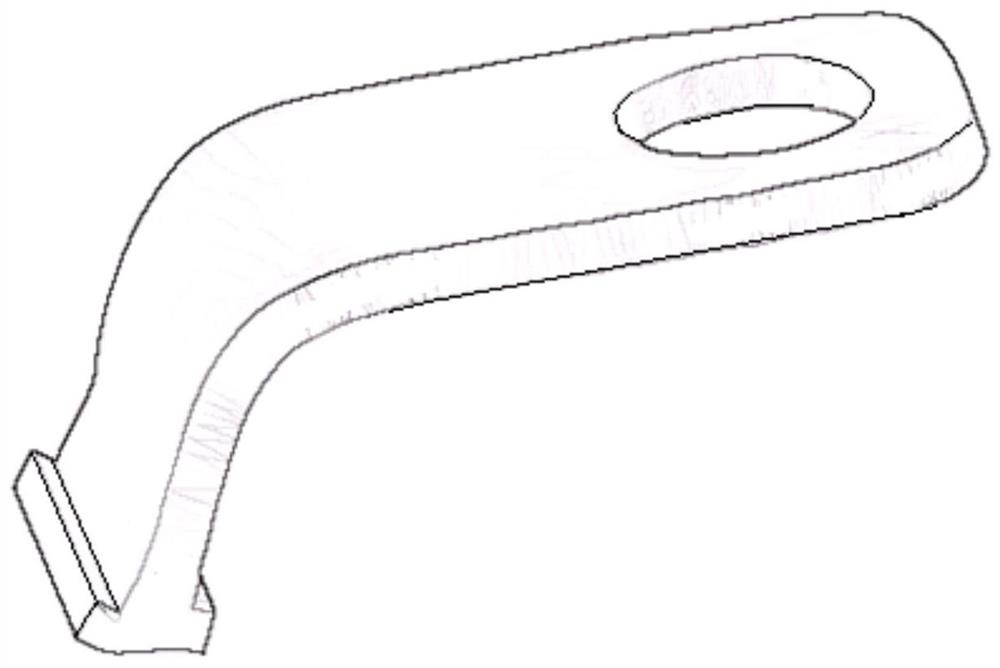

[0026] A method for making a multifunctional edentulous jaw and lipless impression tray of the present invention has the following steps:

[0027] 1) Three-dimensional scanning of the tissue surfaces of the complete denture restorations of three types of edentulous alveolar ridges, large, medium and small, respectively, and three sets of three-dimensional data of the tissue surfaces of the upper and lower dentures were obtained for future use;

[0028] 2) Import the scanned 3D data into the reverse engineering software, and shorten the edge of each set of denture tissue scan data by 1-2mm;

[0029] 3) Negatively offset the tissue surface of the denture scanning data by 2mm;

[0030] 4) Design a spherical structure with a height of 2mm on the offset tissue surface;

[0031] 5) Delete the lip rim in the maxillary denture tissue surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com