Double-manipulator ultrasonic detection method

A technology with dual manipulators and detection methods, which is applied in manipulators, program-controlled manipulators, and the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., and can solve problems such as collisions and attitude constraint errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

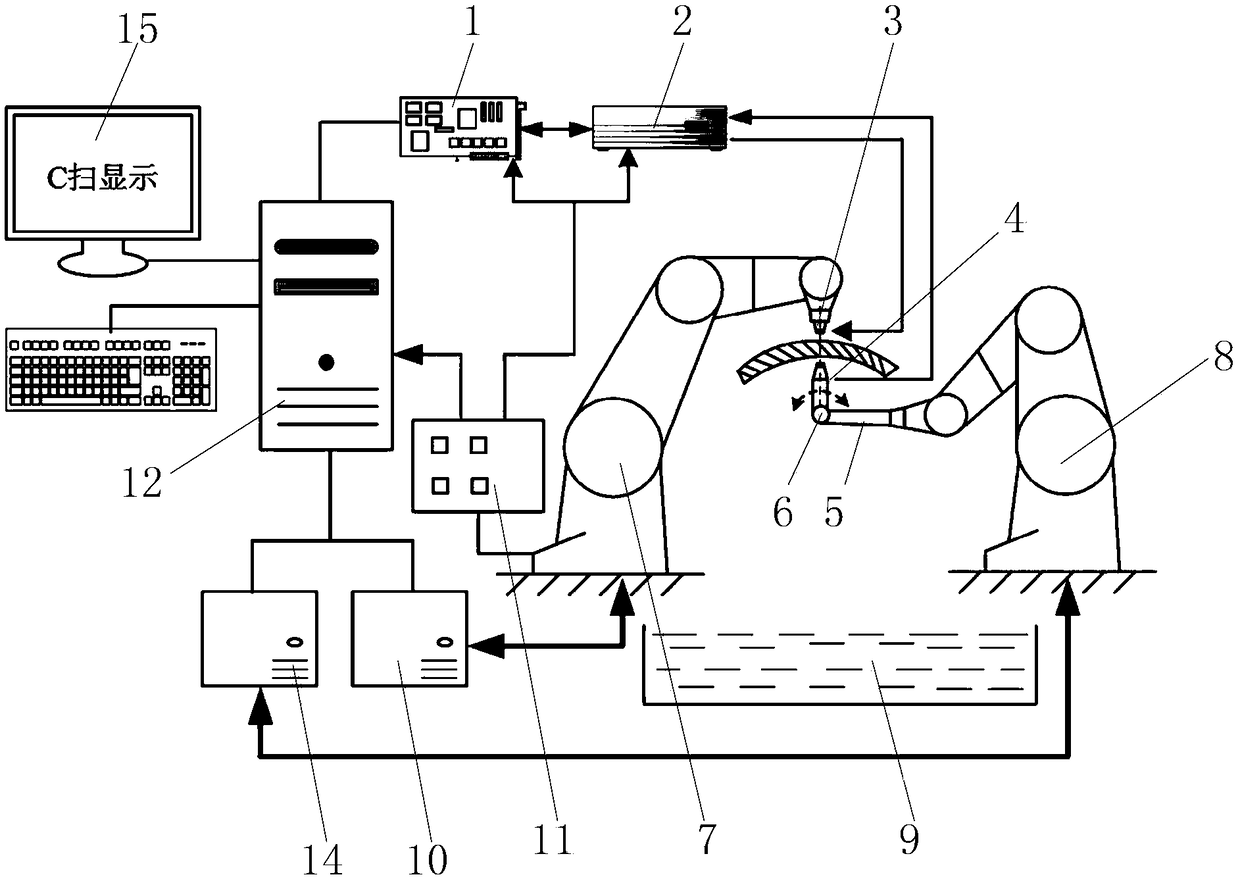

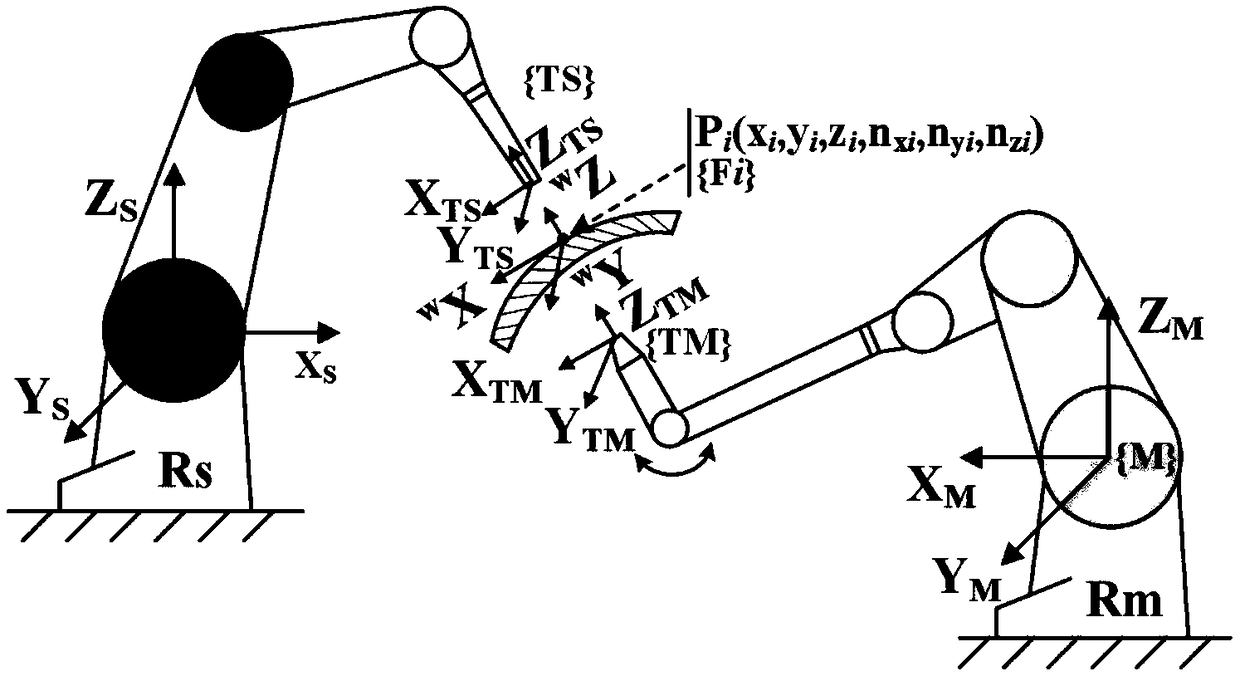

[0048] figure 1 It is a dual-manipulator ultrasonic detection system with an extension rod, which includes an ultrasonic acquisition card 1 for storing ultrasonic data, a pulse transceiver 2 connected to the ultrasonic acquisition card 1 to excite a transmitting probe to transmit ultrasonic waves and a receiving probe to receive ultrasonic waves, Both are connected to the pulse transceiver 2 and installed on the transmitting probe 3 at the end of the master manipulator 7, the receiving probe 4 installed on the extension rod rotation shaft 6, and the extension rod 5 installed between the end of the slave manipulator 8 and the extension rod rotation shaft 6 , the water tank 9 that provides water medium for ultrasonic conduction (wherein the water pump for sucking water in the water tank and the water pipe nozzle sprayed on the workpiece to be inspected are not shown), the master manipulator controller 10 connected with the master manipulator 7, and the slave manipulator 8 The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com