Special bridge crane for brick-making equipment

A special bridge and crane technology, applied in the direction of cranes, trolley cranes, traveling mechanisms, etc., can solve the problems of inconvenient replacement, large mass inertia of moving components, high manufacturing difficulty and high cost, and achieve enhanced emission uniformity and stability, Improve the safety of on-site operations, and the effect of being less prone to falling and tilting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

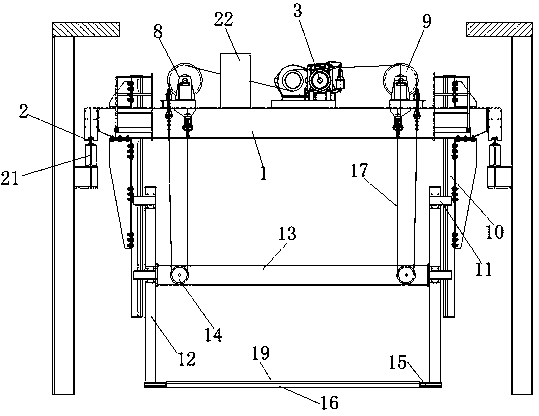

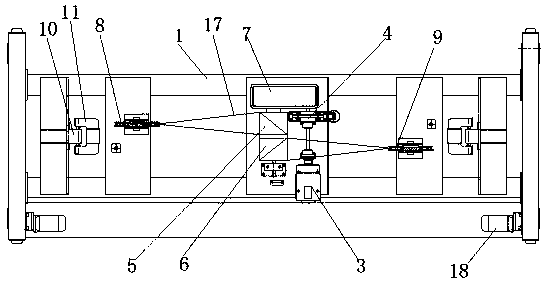

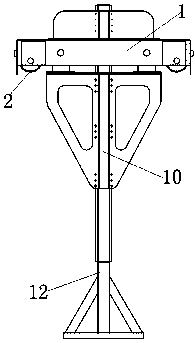

[0022] To make the objectives, technical solutions, and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be described clearly and completely in conjunction with the accompanying drawings in the embodiments of the present invention.

[0023] Such as Figure 1-4 In the illustrated embodiment, a bridge crane dedicated to brick making equipment includes a top base 1 and traveling wheels 2 symmetrically arranged on the left and right sides of the top base 1. The traveling wheels 2 provided on both sides of the top base 1 respectively pass through a drive motor 18 drive; the upper surface of the top seat 1 is equipped with a lifting motor 3, a lifting brake 4, a first lifting drum 5, a second lifting drum 6 and a lifting reducer 7, and the upper surface of the top seat 1 lifting motor 8 and a second top pulley 9 are symmetrically installed on the left and right sides of 3, the top seat 1 is symmetri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com