Conveying robot for wire drawing of waste tires

A technology of waste tires and robots, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems that the spinning of waste tires cannot realize assembly line operations, waste tires cannot be fixed, and cannot continue to be extracted, etc., to ensure Accuracy, firm fixation, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make it easy to understand the technical means, creative features, objectives and effects achieved by the present invention, the present invention will be further explained below in conjunction with specific drawings. It should be noted that the embodiments in this application and the features in the embodiments can be combined with each other if there is no conflict.

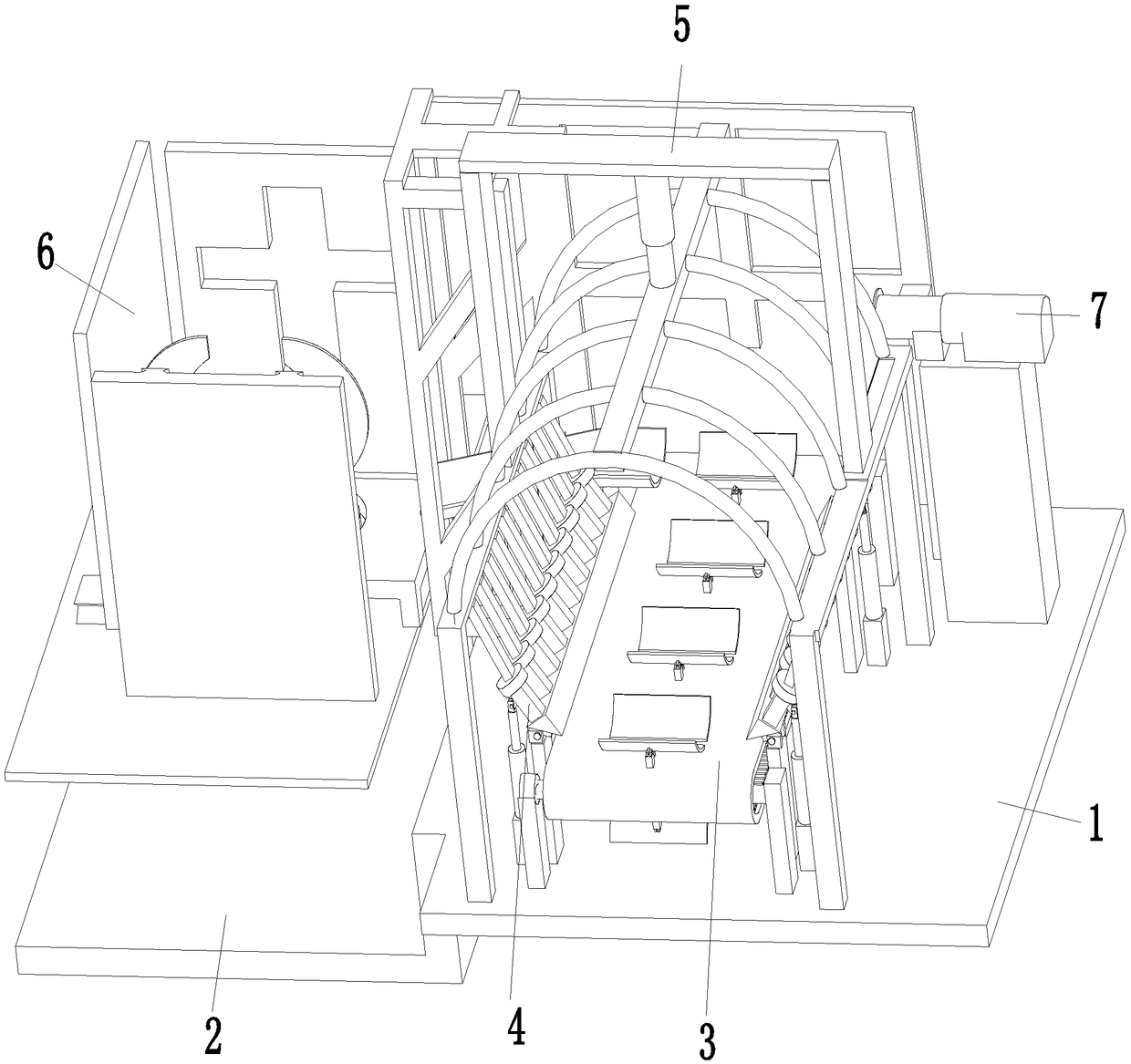

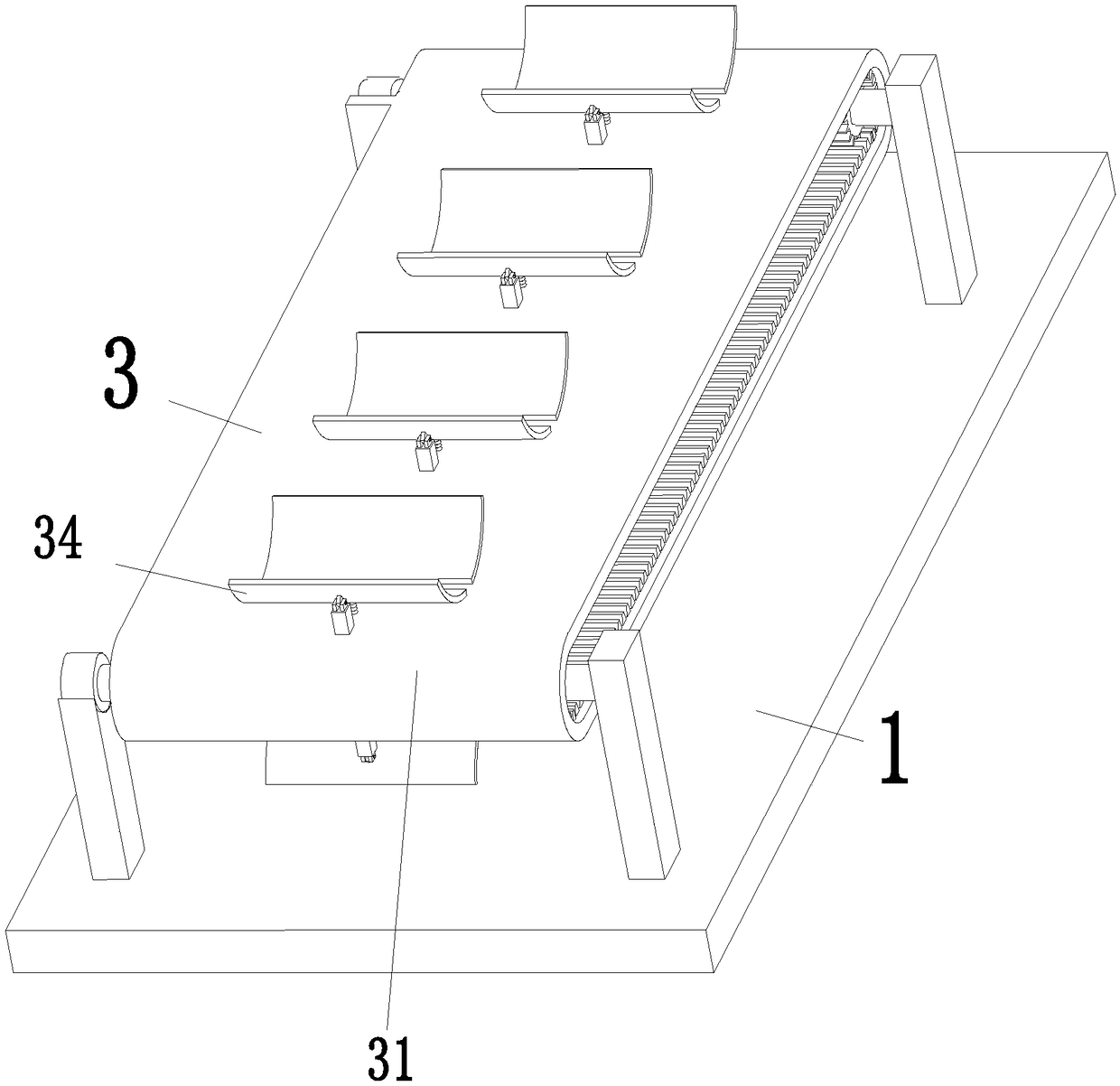

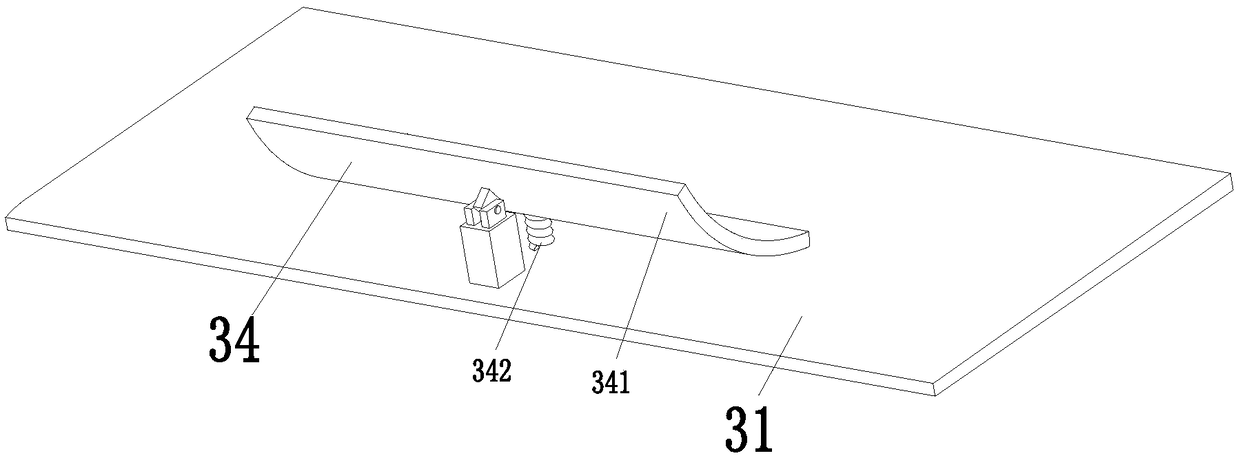

[0031] Such as Figure 1 to Figure 9 As shown, a waste tire threading transfer robot includes a No. 1 bottom plate 1, a No. 2 bottom plate 2, a transmission device 3, an auxiliary device 4, a limit device 5, an execution fixing device 6, and a pushing device 7. The bottom plate 2 is located at the lower left end of the No. 1 bottom plate 1. The lower left end of the No. 1 bottom plate 1 is fixedly connected to the upper right end of the No. 2 bottom plate 2. The transmission device 3 is installed on the middle of the upper end surface of the No. 1 bottom plate 1. The auxiliary device 4 is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com