Device and method for testing ice water erosion resistant performance of concrete

A technology for testing devices and concrete test blocks, which is applied in the direction of measuring devices, material inspection products, optical testing flaws/defects, etc., can solve problems such as time-consuming, complicated test operations, and large sample volume, so as to reduce labor intensity and test The effect of high efficiency and high control precision

Active Publication Date: 2018-12-07

INNER MONGOLIA UNIV OF TECH

View PDF12 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003]

At the present stage, due to the lack of unified test standards for concrete ice water erosion test equipment, many researchers use self-made concrete ice water erosion resistance test machines, which lack uniformity in the shape and size of the samples and lack of comparability; Second, the impact process of ice water and concrete test blocks is simulated, but the influence of temperature on the test process is ignored, so

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

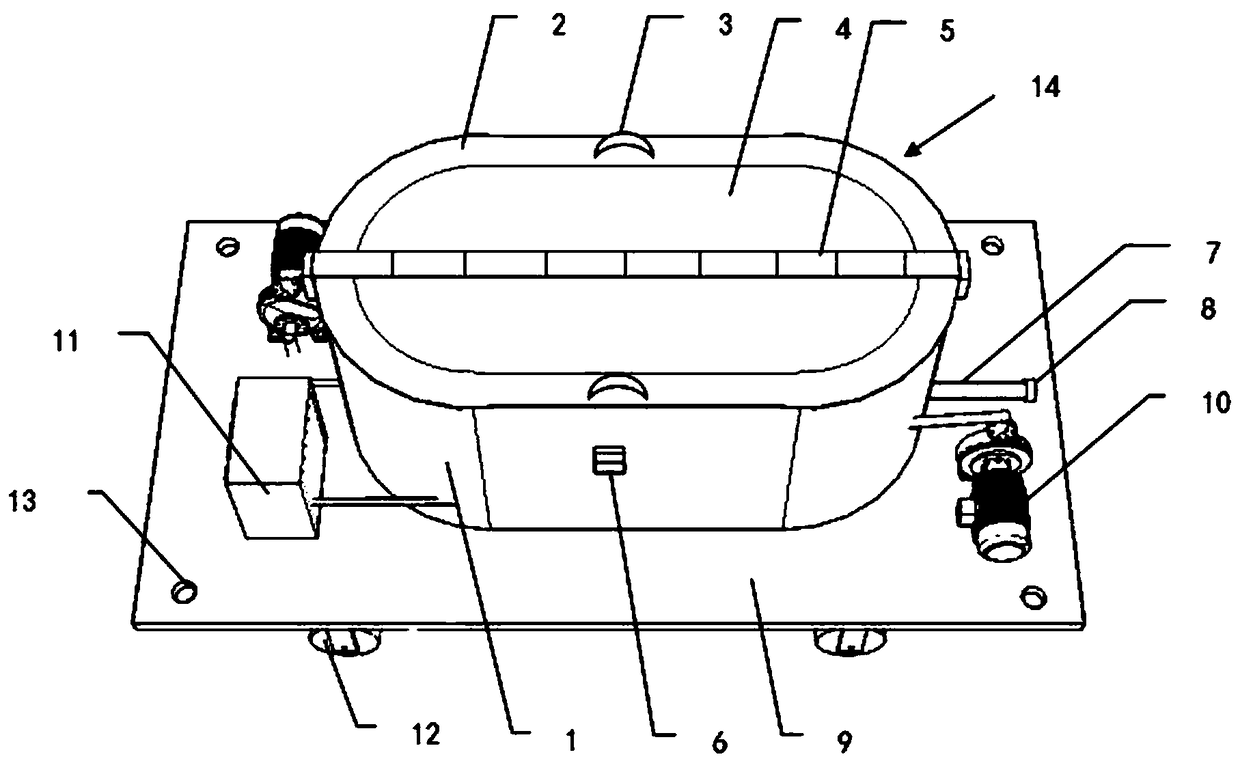

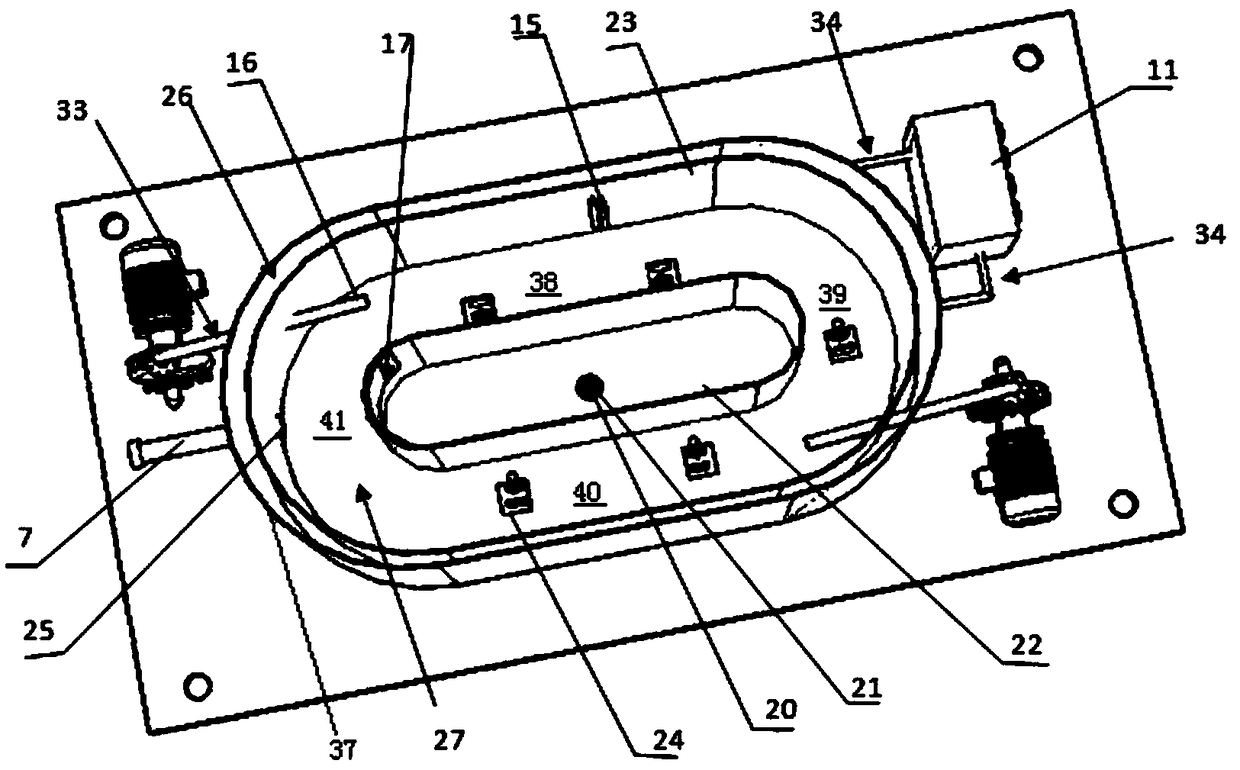

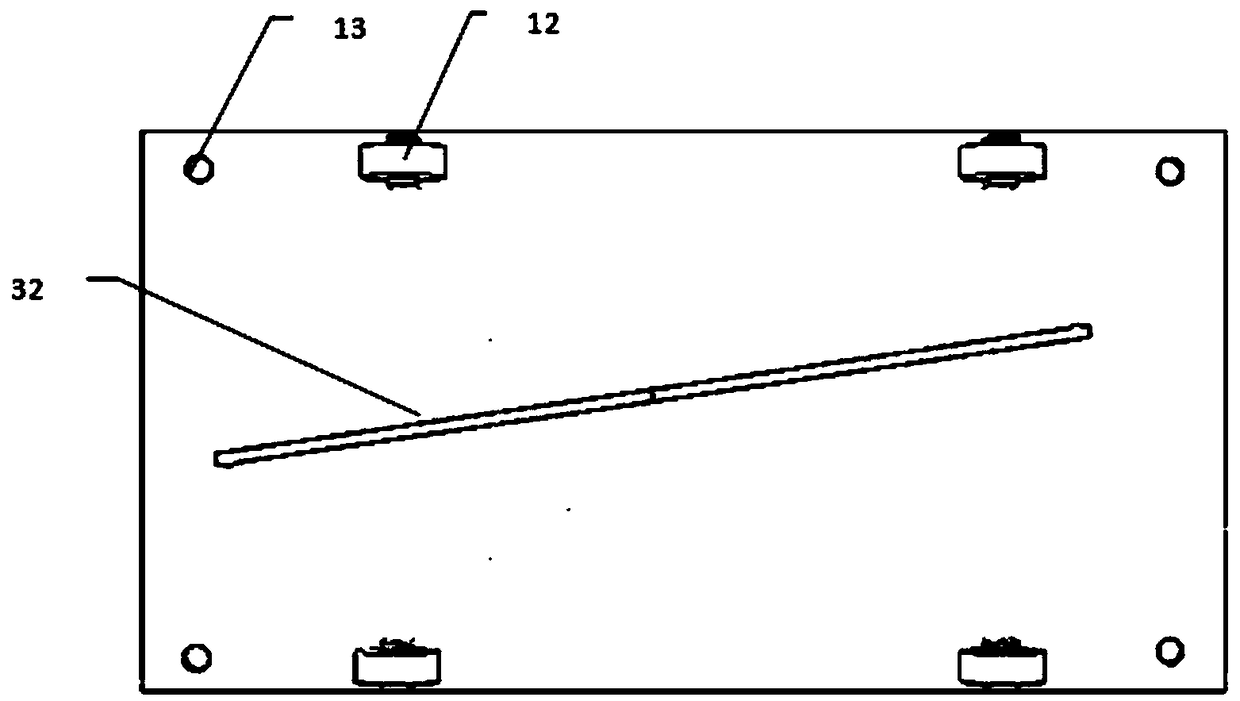

The invention discloses a device for testing the ice water erosion resistant performance of concrete. The device comprises a base plate, a water pump and a low temperature thermostatic water bath arearranged on the base plate; a thermal insulation tank, an outer tank, and an inner tank are arranged on the base plate and form a cooling liquid circulation interlayer and an annular erosion water cavity in sequence. The inner tank is provided with a water flowing gap. A first ice filtering screen is covered on the water flowing gap. Two sides of the water flowing gap are slidingly connected to water level adjusting plates. The interior of the annular erosion water cavity is provided with a water inlet. The bottom of the inner tank is provided with a water outlet. The water outlet is connectedto the water pump. The water pump is connected to the water inlet. A test block fixing support is fixed on the bottom of the annular erosion water cavity. A thermal insulation cover is arranged on the top of a test tank. Two temperature probes measure the temperature of air in the annular erosion water cavity and the temperature of air above the water surface. A temperature display is connected to the first temperature probe and the second temperature probe. The provided device and method can simulate the river ice flood environment in a cold area more realistically and accurately test the ice water erosion resistant performance of concrete.

Description

technical field [0001] The invention relates to the technical field of concrete testing, in particular to a test device and a test method for the anti-icing water erosion performance of concrete. Background technique [0002] Flowing refers to the phenomenon that ice blocks and river water flow together before the river freezes. The Yellow River in my country's Inner Mongolia region or rivers in other areas are prone to ice floods during the closure of the river in winter and the opening of the river in spring. Lots of ice cubes will appear. As the ice moves with the water flow, it will hit the hydraulic structure at a certain speed. The unpredictability of this dynamic load will inevitably affect the safety of the hydraulic structure and reduce the service life of the hydraulic structure. Therefore, in order to ensure the service performance and service life of hydraulic projects in severe cold regions, it is necessary to test and evaluate the anti-ice water erosion perfor...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N33/38G01N21/88G01N5/00

CPCG01N5/00G01N21/8851G01N33/383

Inventor 王萧萧刘曙光闫长旺姜琳

Owner INNER MONGOLIA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com