Device for detecting medical sterile glove for surgery

A detection equipment, a technique for surgery, applied in the direction of detecting the appearance of fluid at the leak point, using liquid/vacuum for liquid tightness measurement, etc., can solve the problems of high labor intensity, low work efficiency, and complicated procedures, etc. Low labor intensity, high work efficiency, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

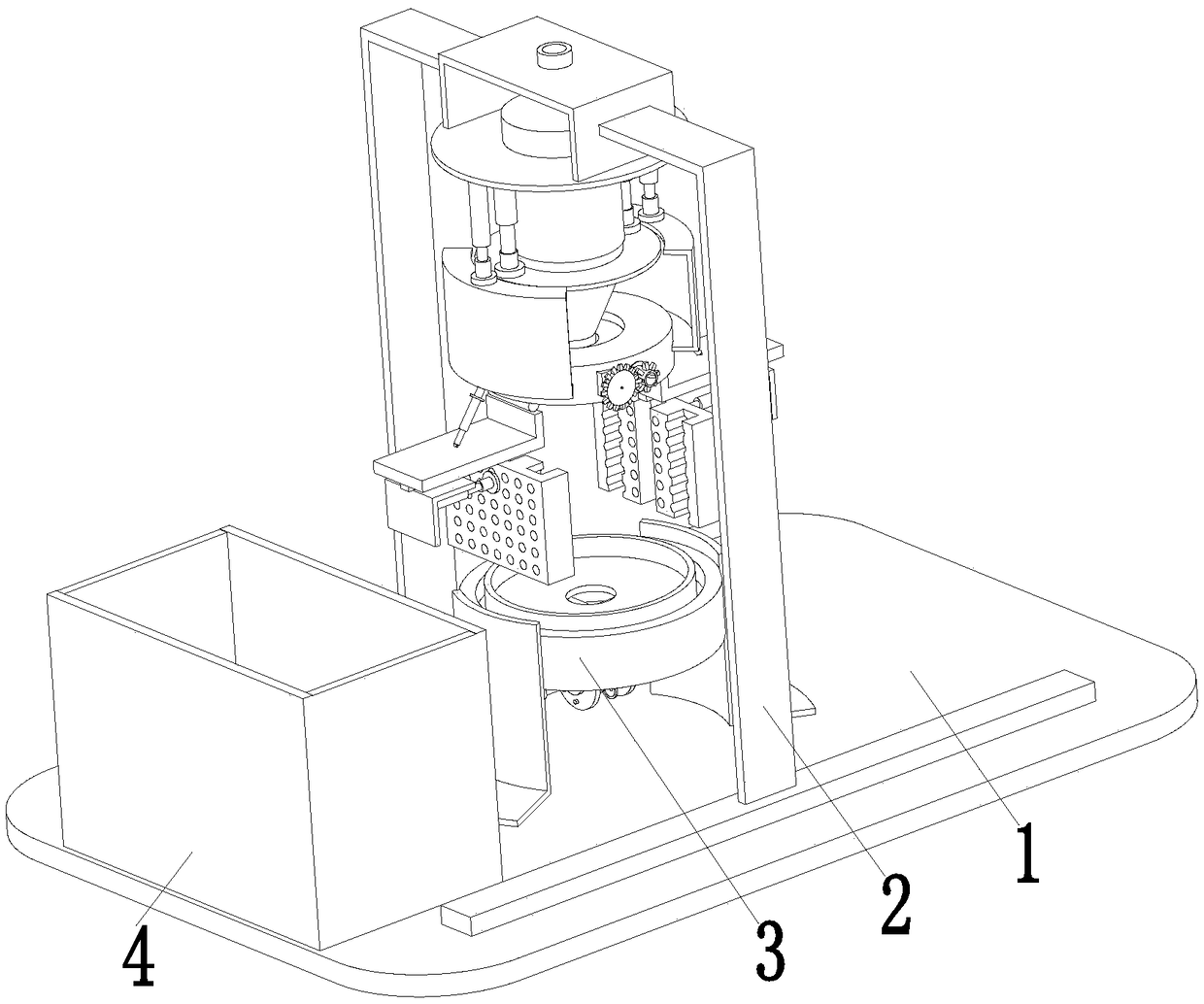

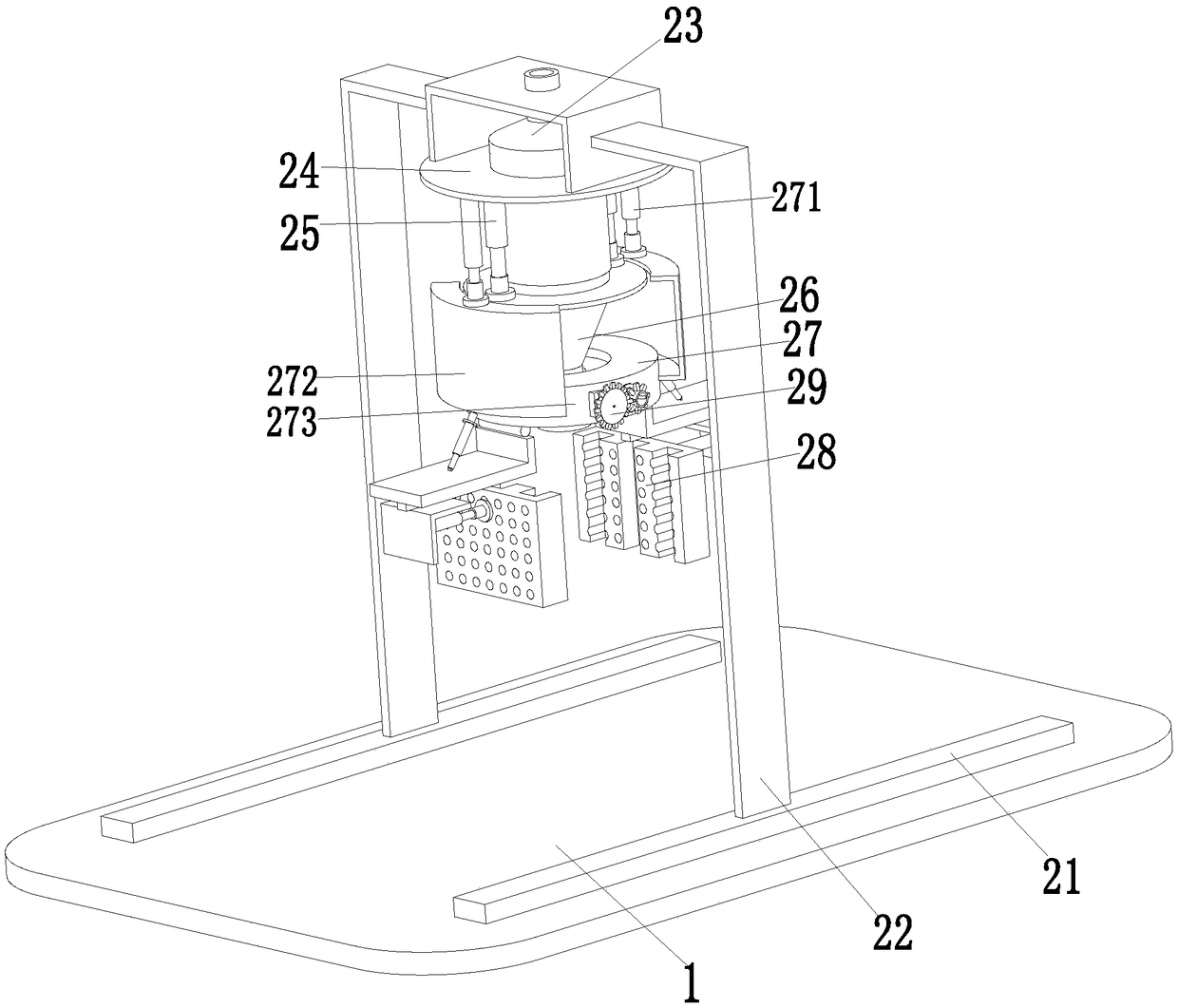

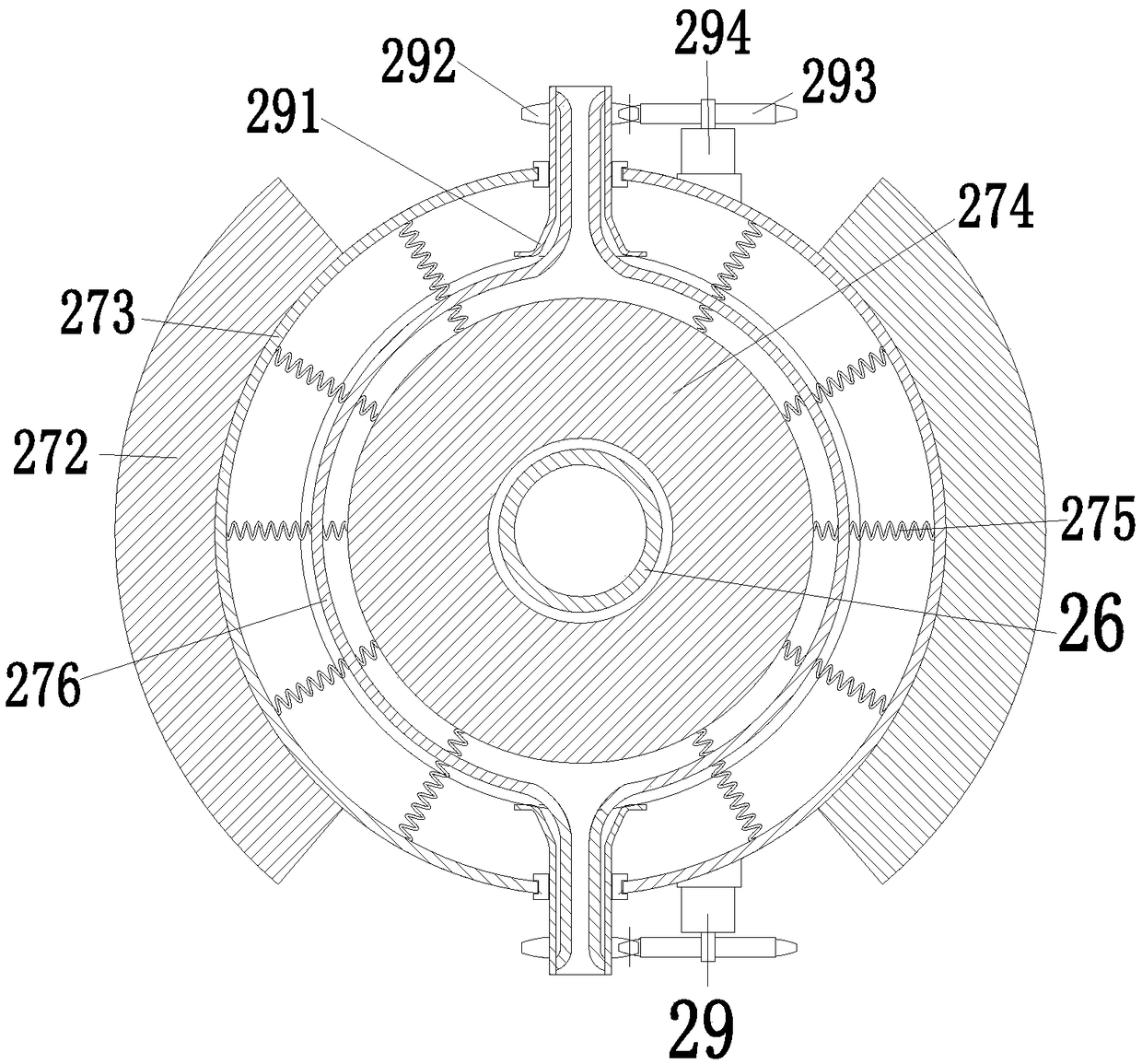

[0024] Such as Figure 1 to Figure 6 As shown, a medical sterile glove testing device for surgery includes a base plate 1 on which a fixed sealing device 2, a tension control device 3 and a test water tank 4 are installed, wherein the tension control device 3 is located at the side of the fixed seal device 2 Directly below, the test water tank 4 is located on the front side of the bottom plate 1, and the test water tank 4 is filled with a special test liquid. The opening and closing control device 3 can control the opening and closing movement of the gloves during work, so that the gloves can be tested with the fixed sealing device 2 Operation, the fixed sealing device 2 can seal the opening of the glove and check the glove with the help of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com